Wire feed plate mechanism for submerged-arc welding

A wire feeder, submerged arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of waste, single function, easy scattered welding wire, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

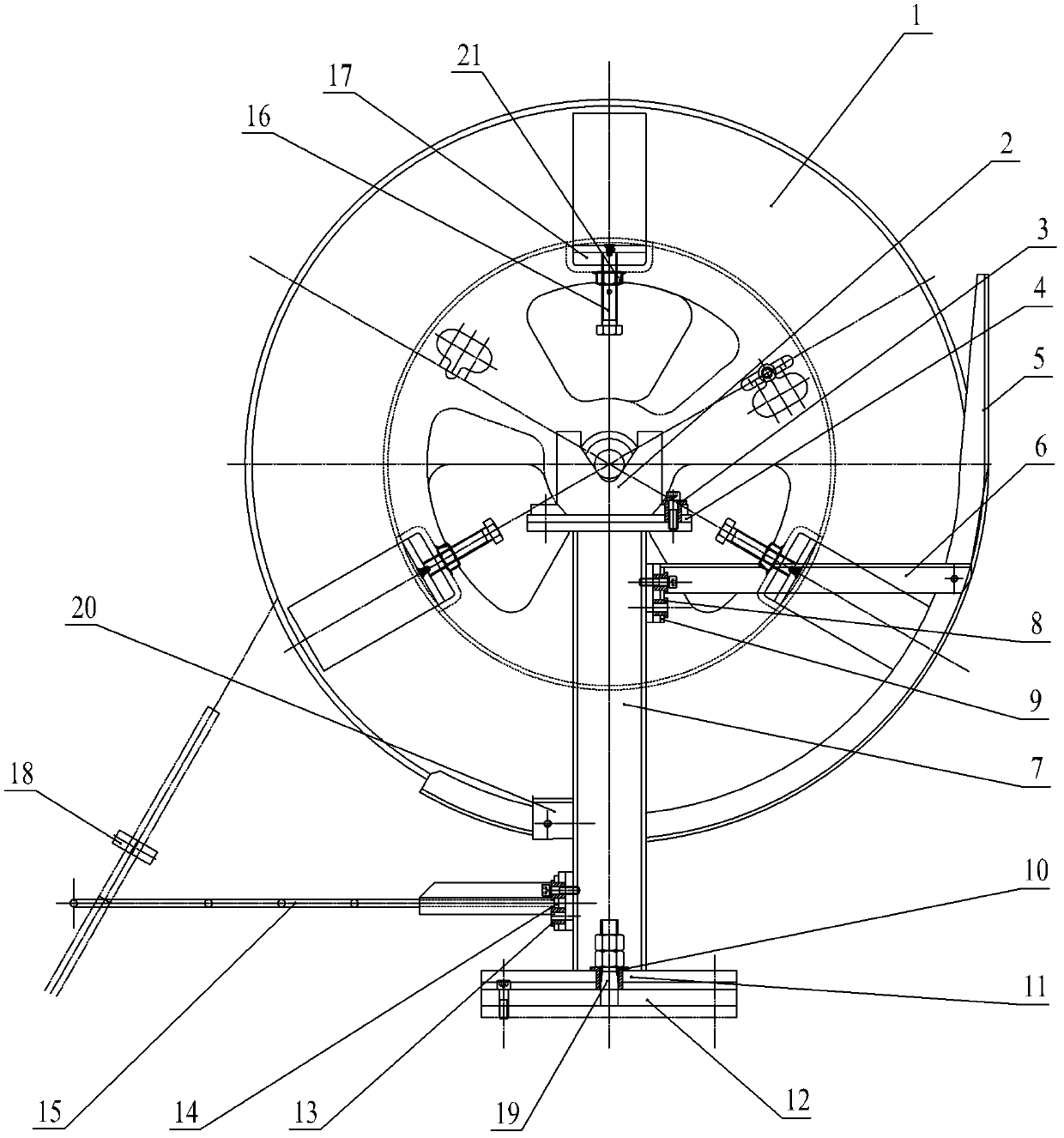

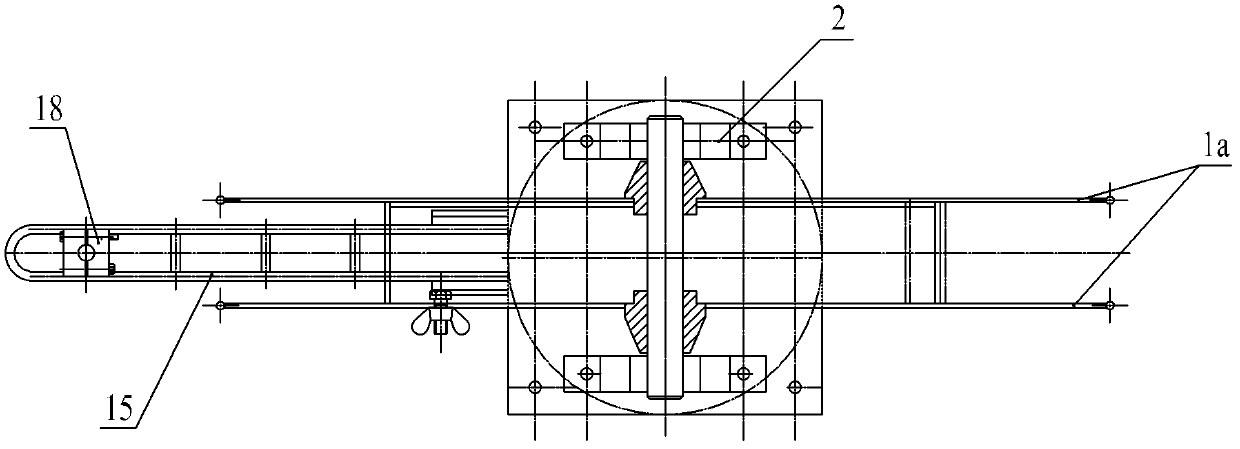

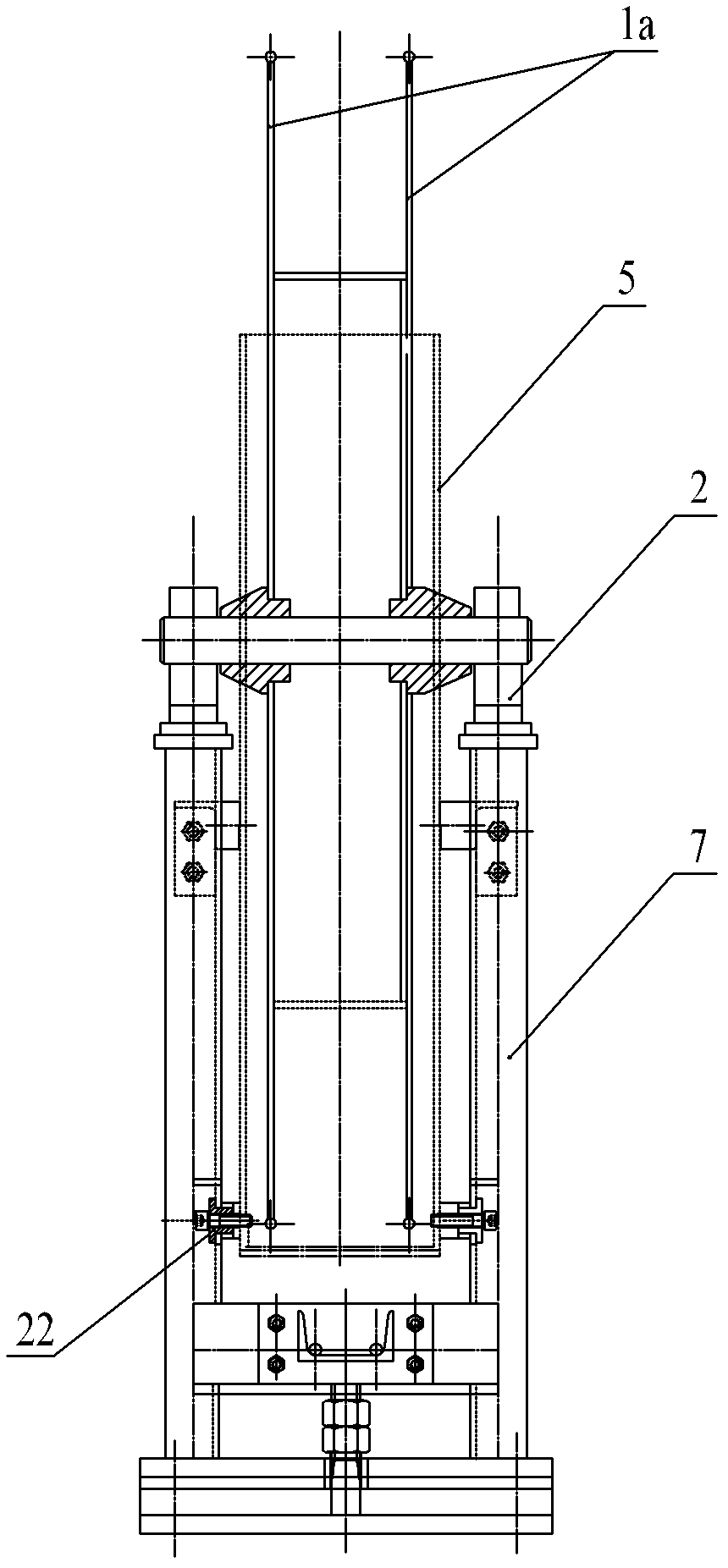

[0014] As shown in the figure: the submerged arc welding wire feeding reel mechanism in the embodiment is mainly composed of a reel frame 1, a shaft seat 2, a first bakelite sleeve 3, a first bakelite board 4, a guard plate 5, an angle iron frame 6, and channel steel legs 7. The second bakelite cover 8, the second bakelite board 9, the third bakelite cover 10, the third bakelite board 11, the bottom plate 12, the fourth bakelite board 13, the fourth bakelite cover 14, the jacket 15, the jacking screw 16, Compression plate 17, conduit clip 18, screw rod 19, connecting plate 20, fixing nut 21 and the fifth Bakelite cover 22 and other parts constitute.

[0015] Such as Figure 1~Figure 3 As shown, the disc frame 1 is installed on the shaft seat 2 through the shaft support of its own center, and the shaft seat 2 is fixedly connected to the top of the channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com