Mechanical arm and fermented beancurd bottling mechanism applying same

A technology of manipulators and fermented bean curd, which is applied in the direction of manipulators, program-controlled manipulators, and manufacturing tools. It can solve the problems of affecting visual effects, poor bottling effect of fermented bean curd, low success rate and low bottling efficiency, etc., to ensure rationality and improve bottling The effect of high efficiency and bottling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

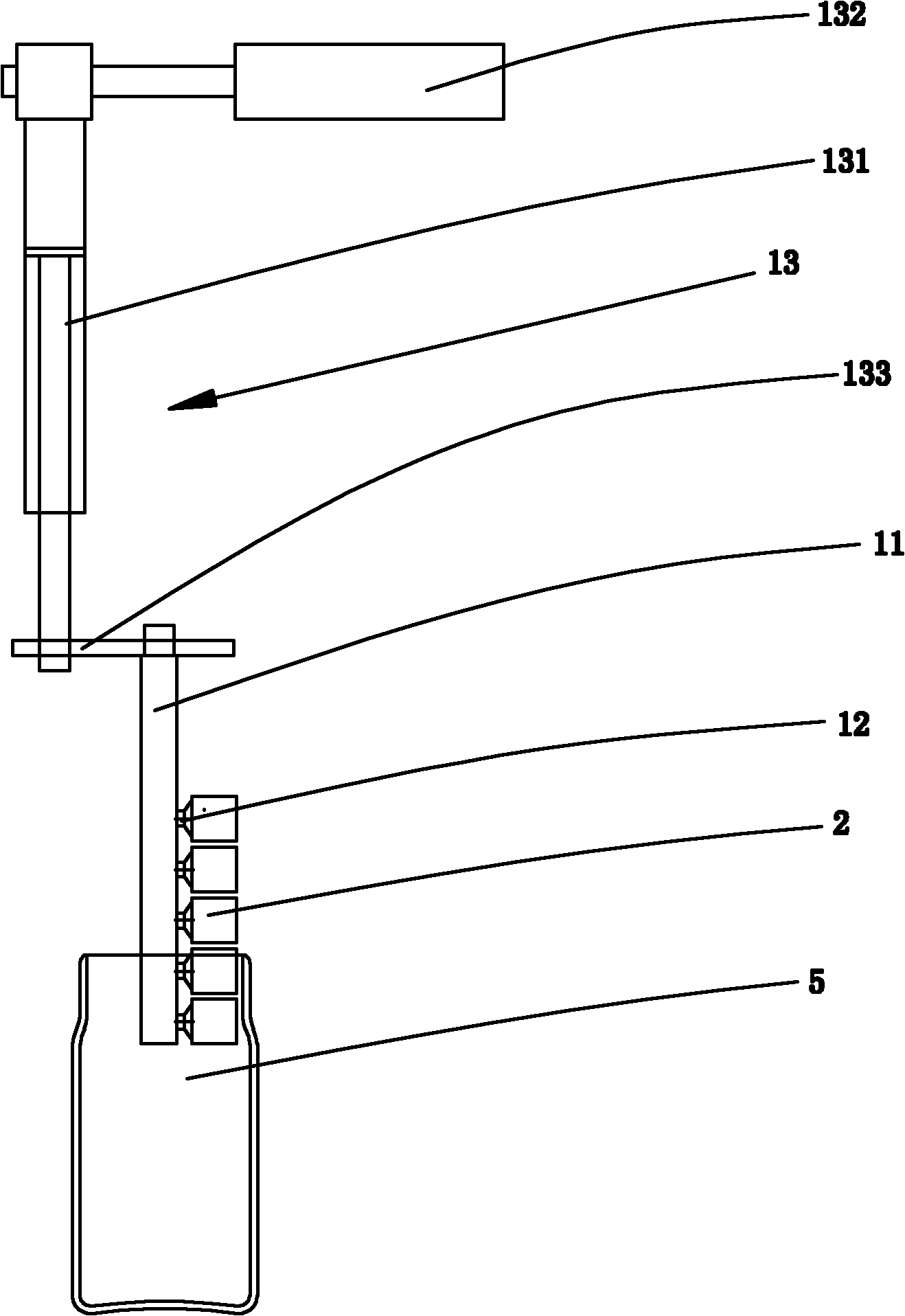

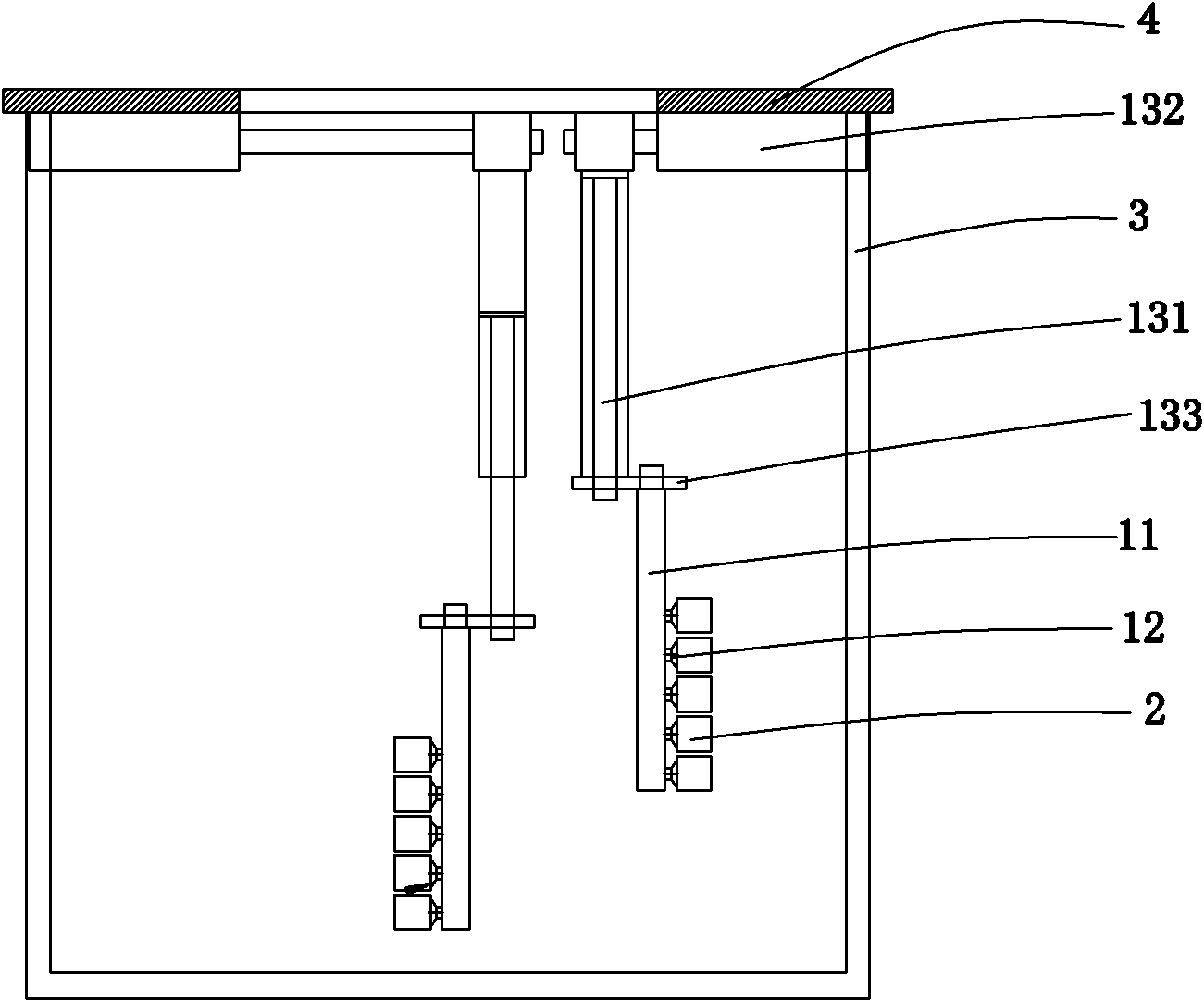

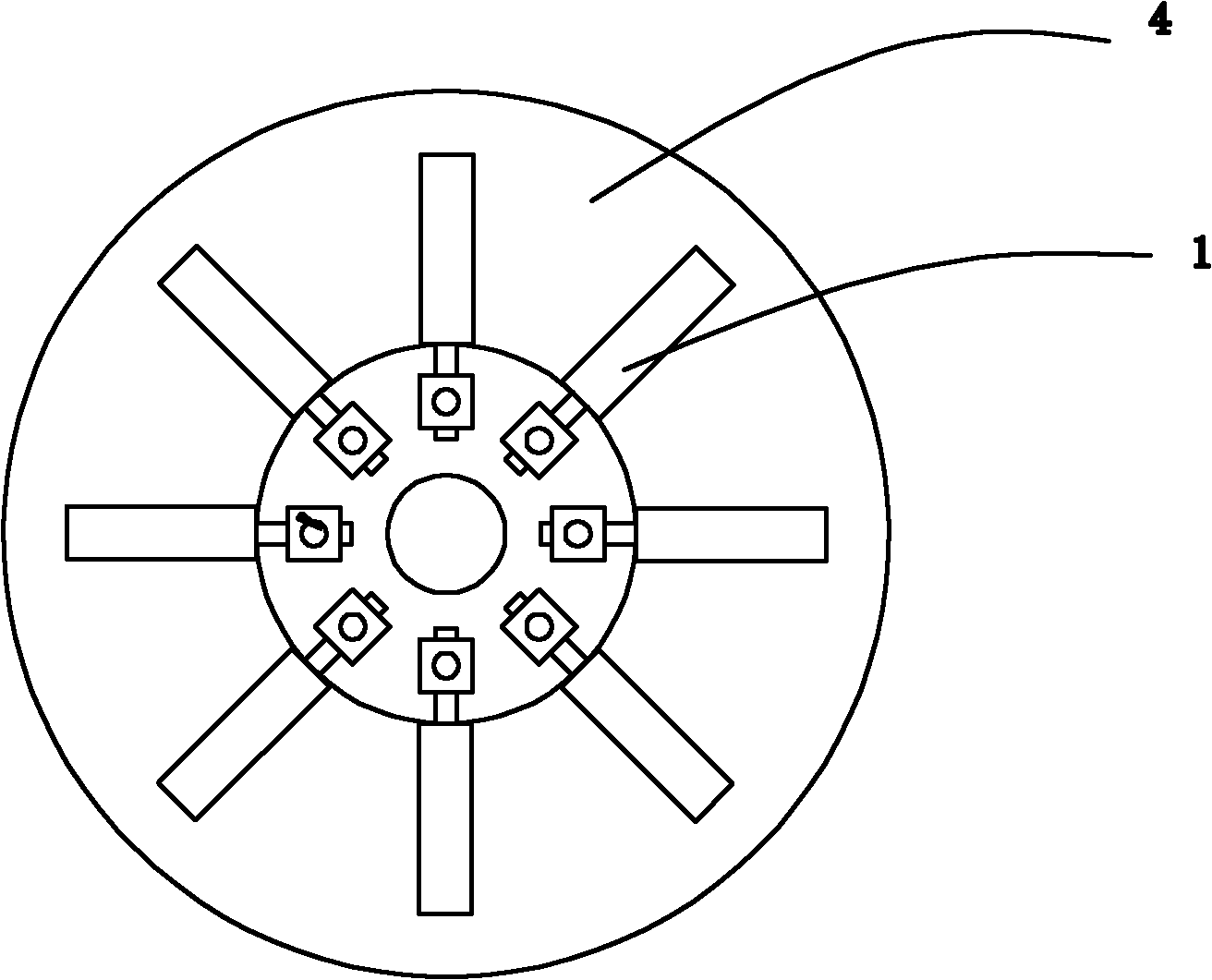

[0016] Such as figure 1 As shown, the manipulator of the present invention includes a longitudinal fixed base 11, and the fixed base 11 is longitudinally equipped with several suction cups 12 for absorbing fermented bean curd 2, and the suction cups 12 are equidistantly distributed on the fixed base 11, and are relatively The distance between the centers of two adjacent suction cups 12 is the thickness of the fermented bean curd 14, so that one suction cup can absorb a piece of fermented bean curd, and the arrangement of the fermented bean curd is more orderly. The fixed seat 11 is driven by the transmission mechanism 13 to move up, down, forward and backward. The transmission mechanism 13 includes a transverse connecting rod 133 connected to the fixed seat 11, and the other end of the connecting rod 133 is connected to a longitudinal cylinder 131. The other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com