Bouquet processing production line and production method

A production line and bouquet technology, applied in the production line of flower bouquets, can solve the problems of unguaranteed pruning effect, low efficiency, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

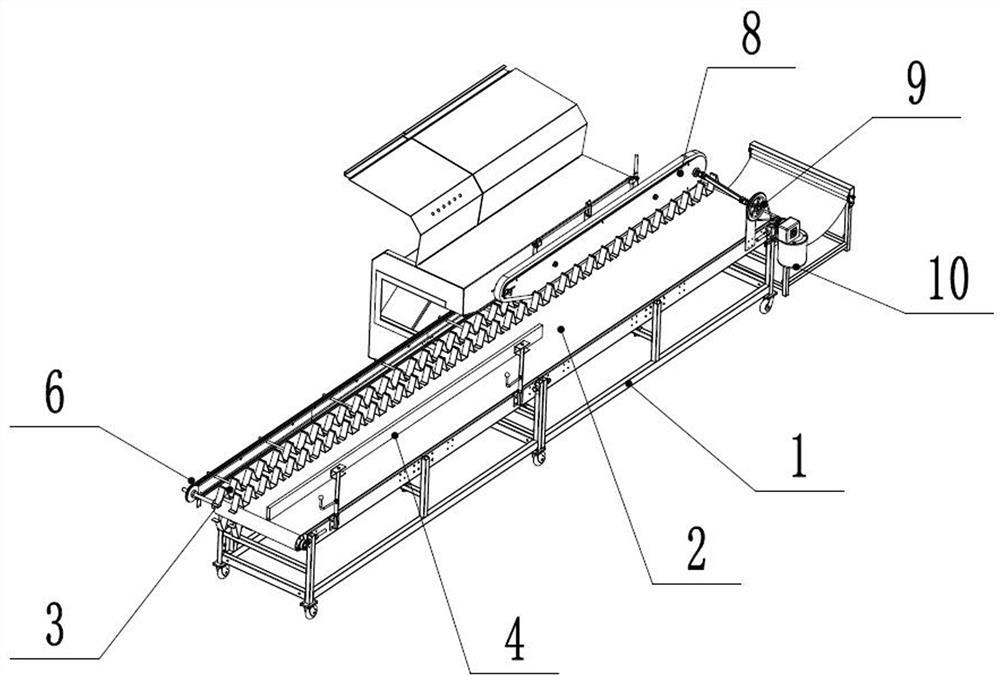

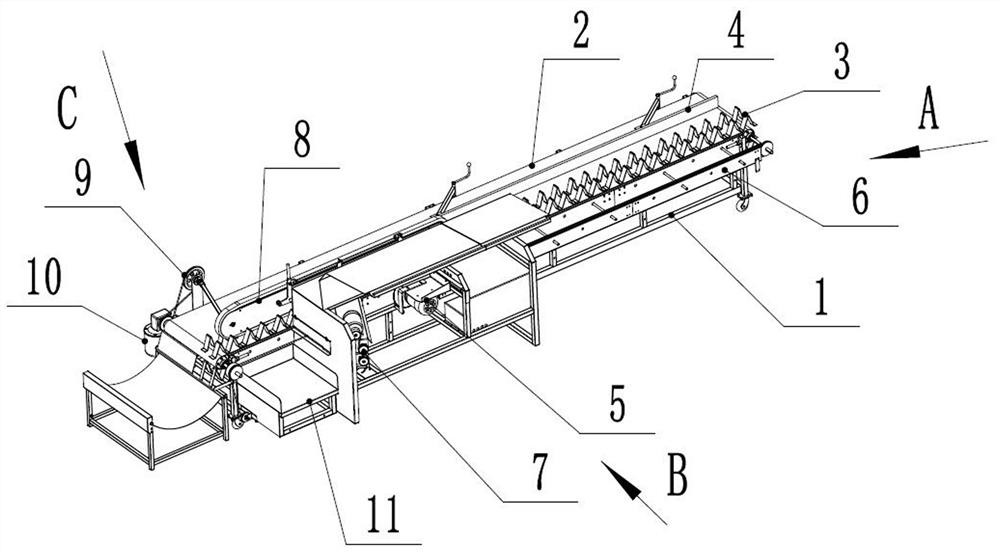

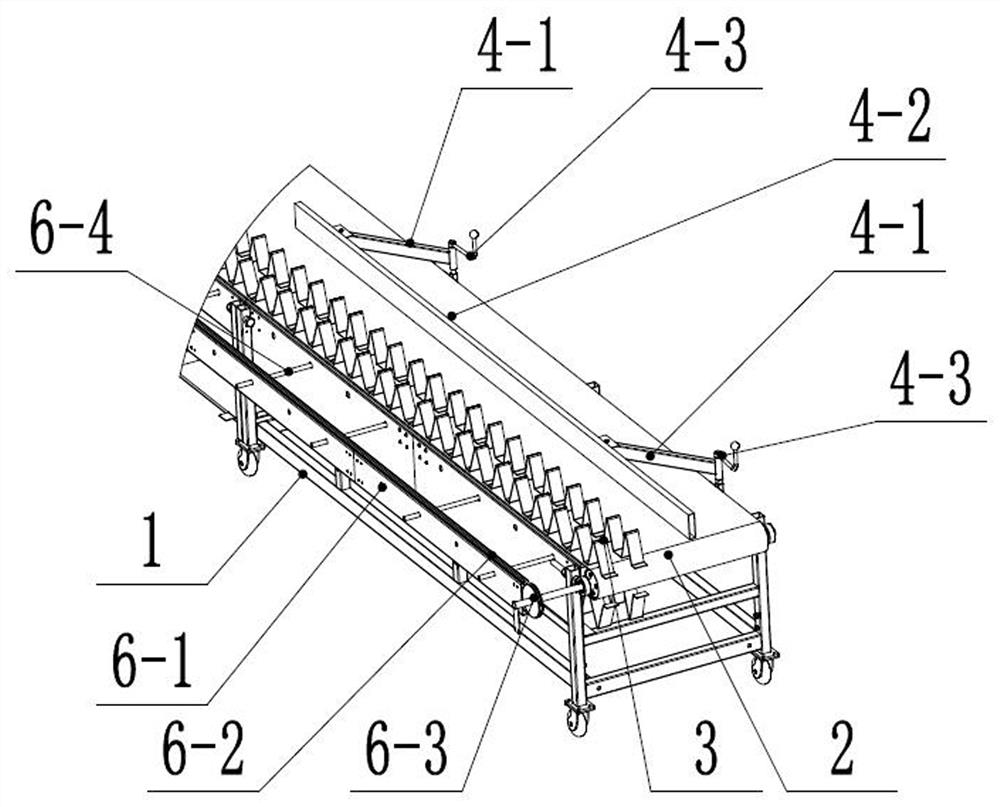

[0060] like figure 1 and 2 , a bouquet processing production line and production method, comprising a frame 1, the frame 1 is equipped with a conveyor belt 2; the conveyor belt 2 is provided with a plurality of partitions 3 along the conveying direction, and the partitions 3 are configured to place bouquets. empty slot.

[0061] The frame 1 also includes a translation positioning device 4 , a cutting device 5 , a carding device 7 and an automatic strapping machine placed on the strapping station 11 arranged in sequence along the conveying direction of the conveyor belt 2 .

[0062] The translation positioning device 4 is used to align the tops of the fresh flowers; the cutting device 5 is used to cut the roots of the fresh flowers; the combing device 7 is used to remove redundant branches and needles on the fresh flowers by whipping.

[0063] Beside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com