Rotary corona discharge low temp plasma source apparatus

A low-temperature plasma and corona discharge technology, applied in the direction of plasma, discharge tube, circuit, etc., can solve the problems of energy density and active particle concentration flow field uniformity to be improved, so as to improve the flow field uniformity and improve the activity Effect of particle concentration and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

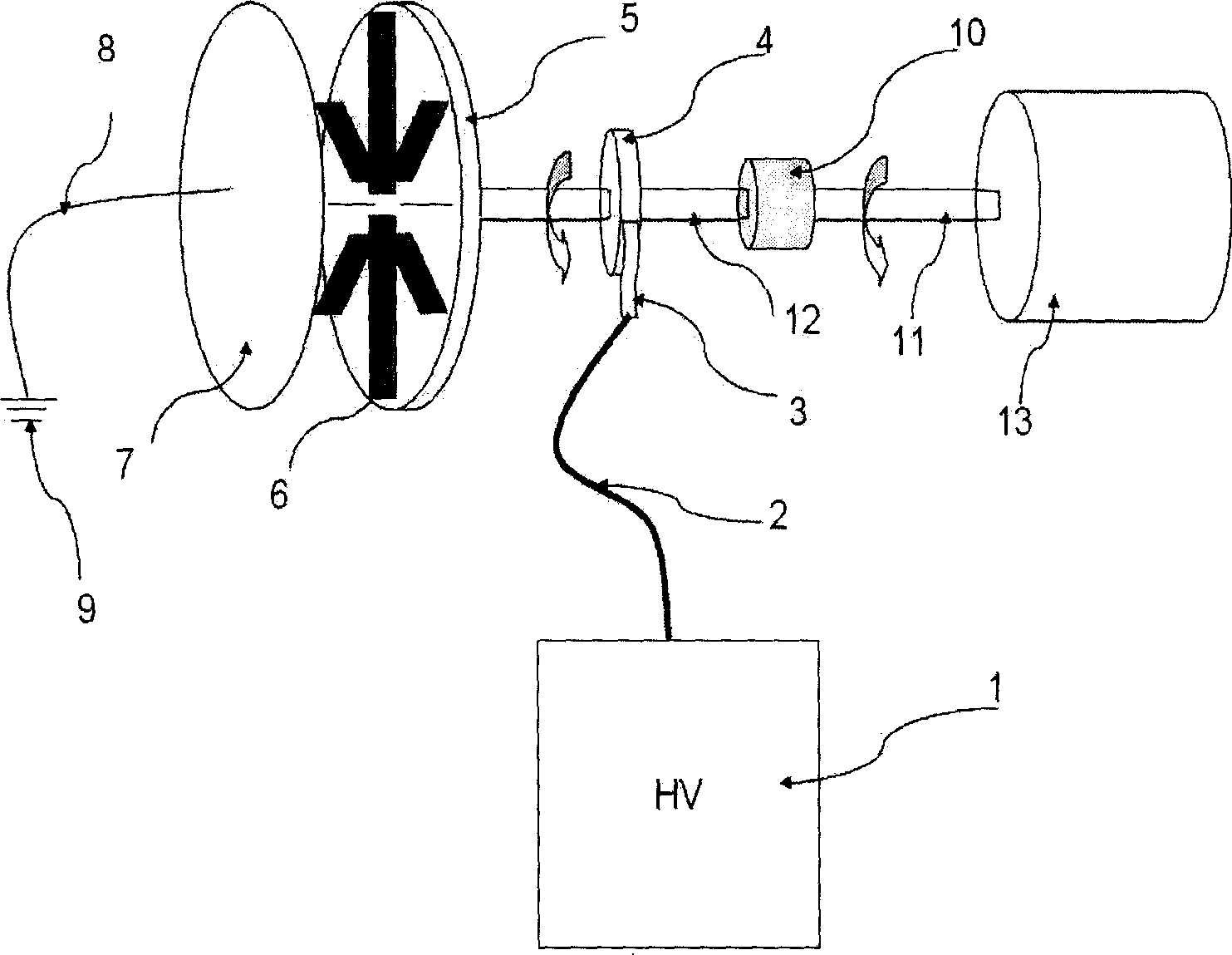

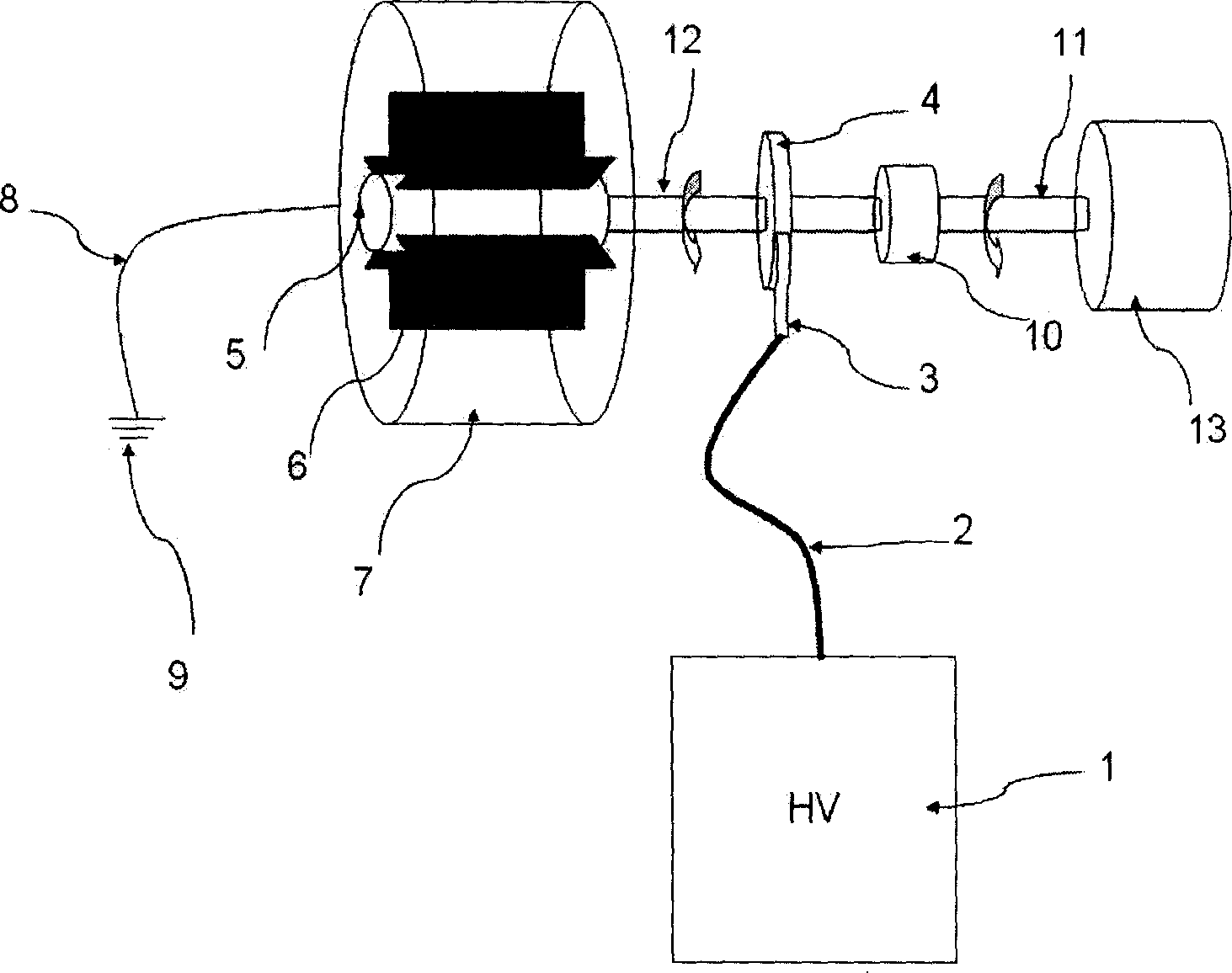

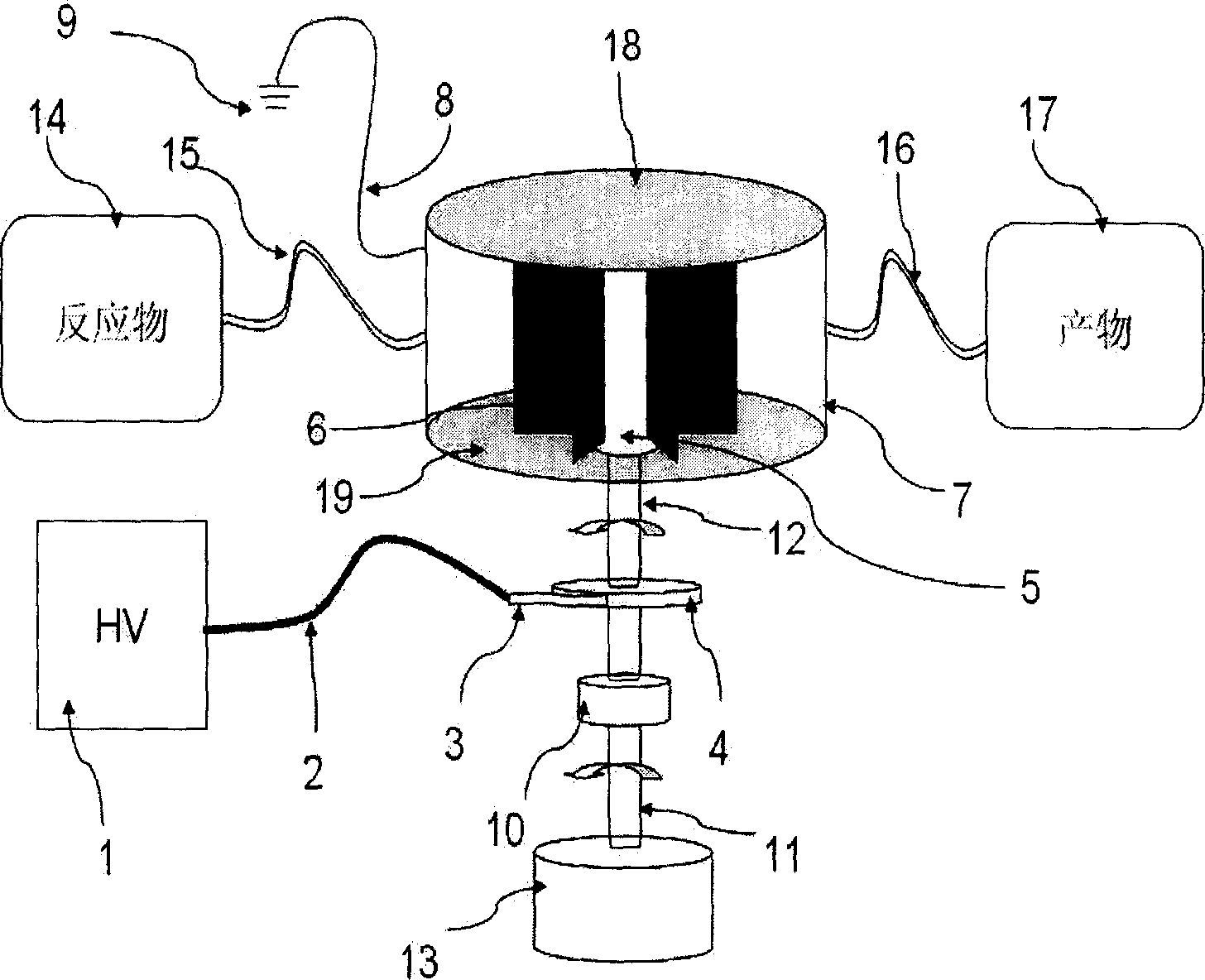

[0012] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

[0013] This specific embodiment will be used to carry out chemical raw material synthesis. The high-voltage electrode is composed of a high-voltage electrode curved plate 5 and an array of ultra-thin sheet electrodes 6 . Both the curved plate of the cylindrical high voltage electrode and the ultra-thin sheet electrode are made of stainless steel, and the surface of the ultra-thin sheet electrode is coated with platinum to prevent corrosion. The high-voltage electrode is rigidly connected to the high-voltage electrode drive shaft 12. The high-voltage electrode drive shaft is made of stainless steel and has a slip ring 4 on the outside. The power source drive shaft 11 is connected to the high-voltage electrode drive shaft through an insulating connection 10. The insulating connection is a contact insulating con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com