Organic waste gas degradation method based on dielectric barrier discharge

A technology of dielectric barrier discharge and organic waste gas, applied in the field of ions, can solve problems such as substandard degradation rate, and achieve the effect of improving degradation efficiency, changing discharge electric field strength, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

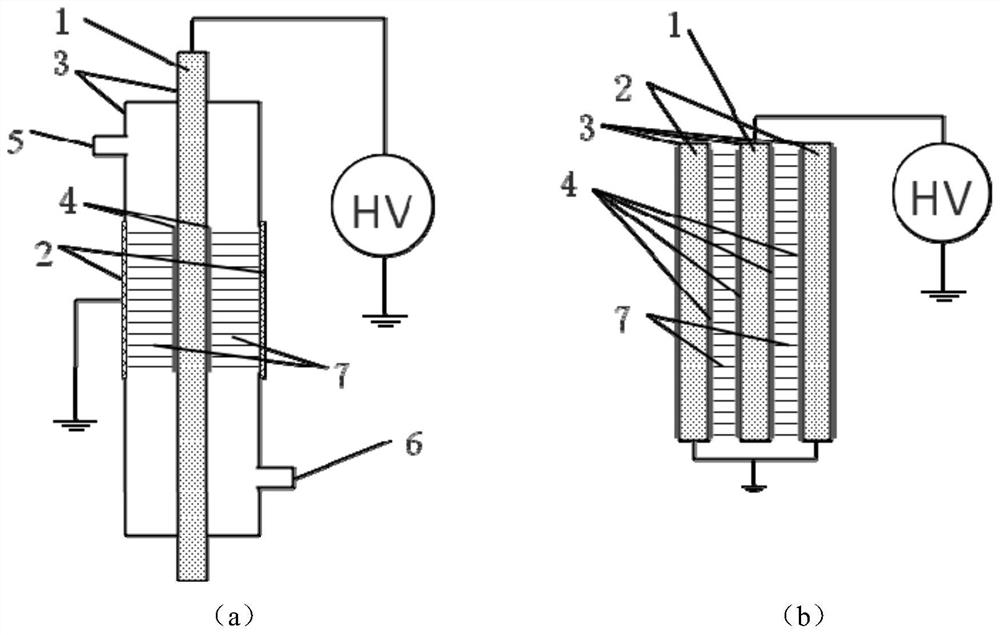

[0044] by figure 1 The coaxial tubular dielectric barrier discharge low-temperature plasma reactor in a, wherein the high-voltage electrode 1 with a dielectric tube in the center is coaxially sleeved in the barrier dielectric tube 3 (specifically, quartz), and the ground electrode 2 is wrapped in the barrier dielectric tube On the outer wall of 3, an air inlet 5 and an air outlet 6 are provided on the outer wall of the barrier medium tube 3, and the discharge area 7 formed by the gap between the outer wall of the medium high voltage electrode 1 and the inner wall of the barrier medium tube 3 is located in the center, The fluorine-containing material coating 4 is located on the surface of the outer dielectric tube of the tubular high-voltage electrode 1 .

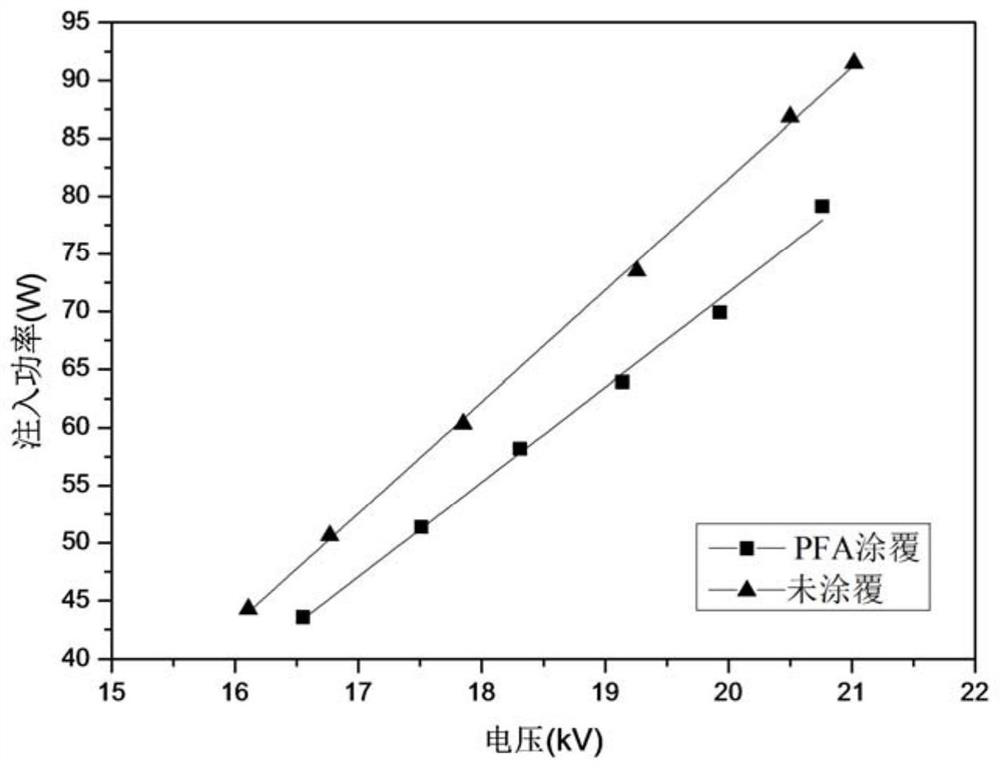

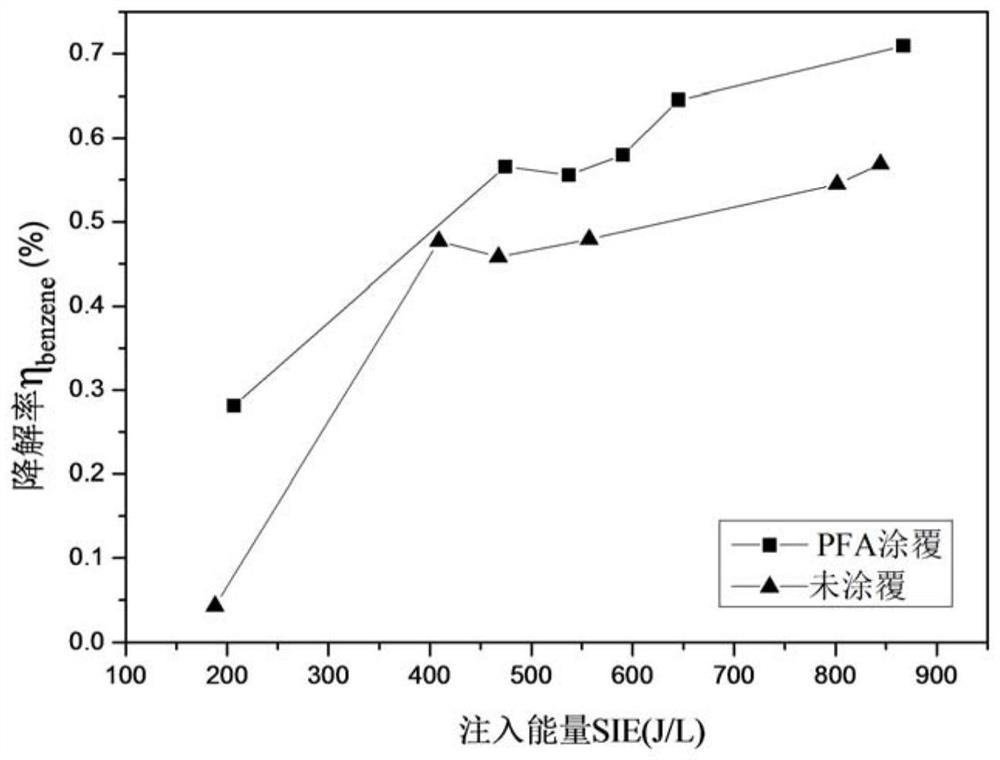

[0045] PFA is sprayed by physical spraying method, wherein, the inner diameter of the outer tube of the coaxial tubular dielectric barrier discharge low-temperature plasma reactor is 18mm, the barrier medium layer is 2mm, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com