Micro lithium-rich high-energy-density lithium cobalt oxide positive pole material and preparation method thereof

A technology of density lithium cobalt oxide, cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unstable crystal structure, inability to ensure high discharge specific capacity, etc., to improve cycle performance, high energy density, discharge The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a slightly lithium-rich high energy density lithium cobalt oxide positive electrode material provided by the present invention comprises the following steps:

[0021] Step 1, weighing cobalt salt, aluminum salt and nickel salt according to a certain metal molar ratio, dissolving them in deionized water, and preparing salt solution A;

[0022] Specifically, the cobalt salt, aluminum salt and nickel salt are respectively CoSO 4 、Al 2 (SO 4 ) 3 、NiSO 4 , CoSO 4 、Al 2 (SO 4 ) 3 、NiSO 4 Weigh according to the molar ratio of metal Co:Al:Ni (80-96):(2-10):(2-10), and the metal ion concentration in salt solution A is 1mol / L.

[0023] Step 2, preparing NaOH solution and ammonia solution;

[0024] Specifically, the concentration of the NaOH solution is 2 mol / L, and the concentration of the ammonia solution is 1 mol / L.

[0025] Step 3, adding a certain amount of deionized water and ammonia water in the reactor as the reaction bottom liquid in the ...

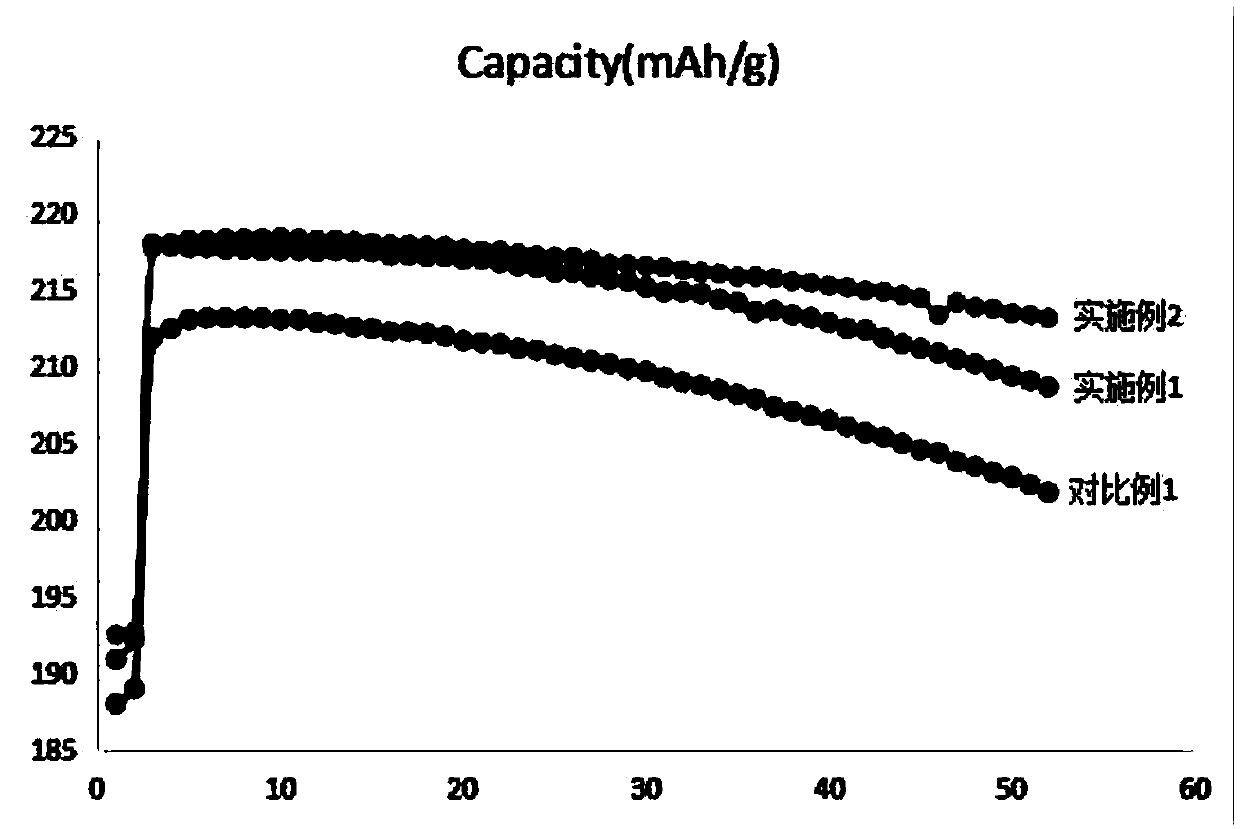

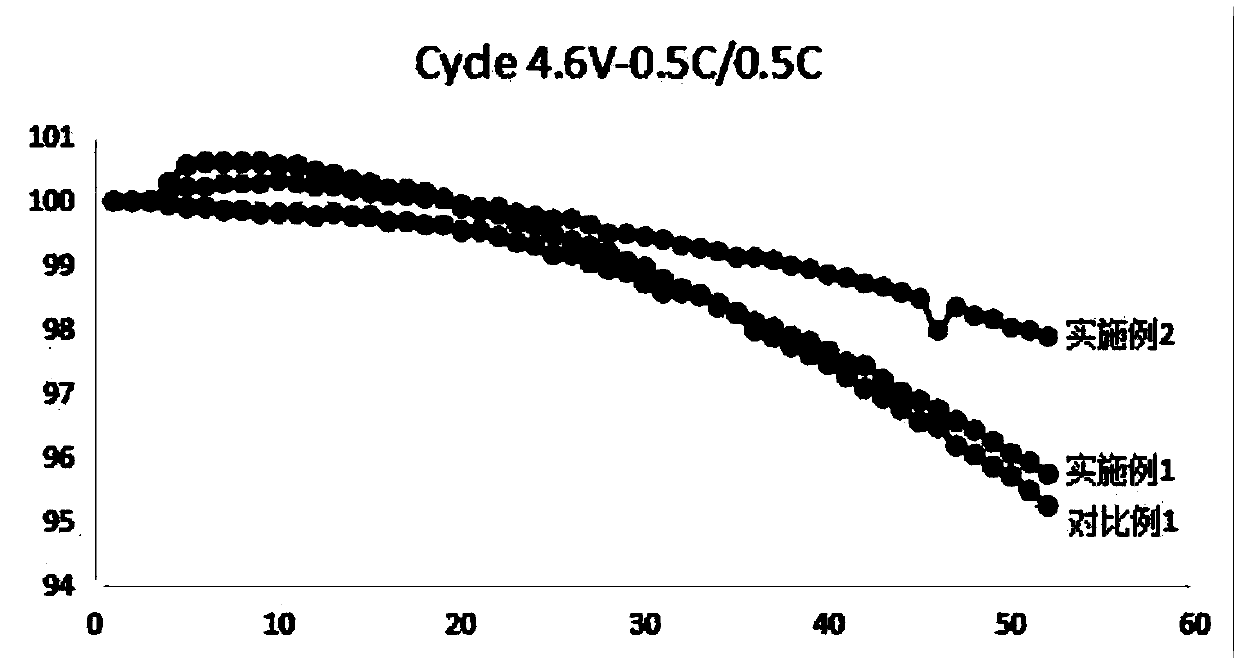

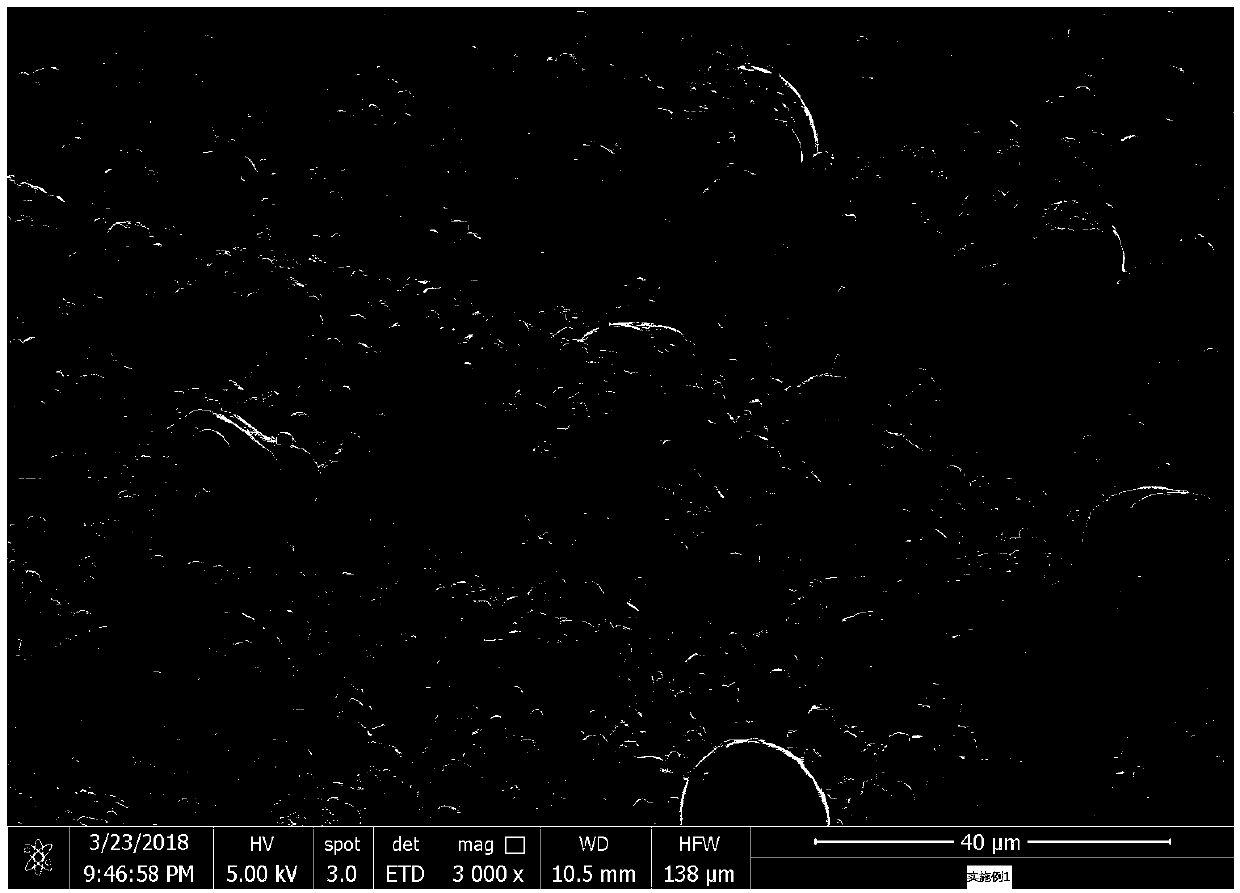

Embodiment 1

[0041] 1) CoSO 4、Al 2 (SO 4 ) 3 、NiSO 4 Weigh according to the ratio of Co:Al:Ni 92:3:5, dissolve in deionized water, and make salt solution A with a metal ion concentration of 1mol / L 1 ; Configure the NaOH alkali solution with a concentration of 2mol / L and the ammonia solution with a concentration of 1mol / L. Add a certain amount of deionized water and ammonia water into the reaction kettle, and configure a 0.5mol / L ammonia solution as the reaction bottom liquid. Then the saline solution A 1 , NaOH solution and ammonia solution are added to the reaction kettle at a certain flow rate at the same time to form a mixture, and a part of the mixture is taken for co-precipitation reaction for 12 hours to obtain a mixed solution of precipitated particles with a suitable particle size, and the mixed solution of precipitated particles is aged for 12 hours, washed The sediment was washed several times until the washing solution was neutral, then filtered, dried in an oven at 120°C,...

Embodiment 2

[0045] 1) CoSO 4 、Al 2 (SO 4 ) 3 、NiSO 4 Weigh according to the ratio of Co:Al:Ni 92:2:6, dissolve in deionized water, and make salt solution A with metal ion concentration of 1mol / L 1 ; Configure the NaOH alkali solution with a concentration of 2mol / L and the ammonia solution with a concentration of 1mol / L. Add a certain amount of deionized water and ammonia water into the reaction kettle, and configure a 0.5mol / L ammonia solution as the reaction bottom liquid. Then the saline solution A 1 , NaOH solution and ammonia solution are added to the reaction kettle at a certain flow rate at the same time to form a mixture, and a part of the mixture is taken for co-precipitation reaction for 12 hours to obtain a mixed solution of precipitated particles with a suitable particle size, and the mixed solution of precipitated particles is aged for 12 hours, washed The sediment was washed several times until the washing solution was neutral, then filtered, dried in an oven at 120°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com