Fluid conduit system and fittings therefor

a conduit system and flue pipe technology, applied in the direction of pipe joints, non-disconnectible pipe joints, manufacturing tools, etc., can solve the problems of increasing the difficulty of making sweat solder connections, affecting the performance of the system, and affecting the service life of the system,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

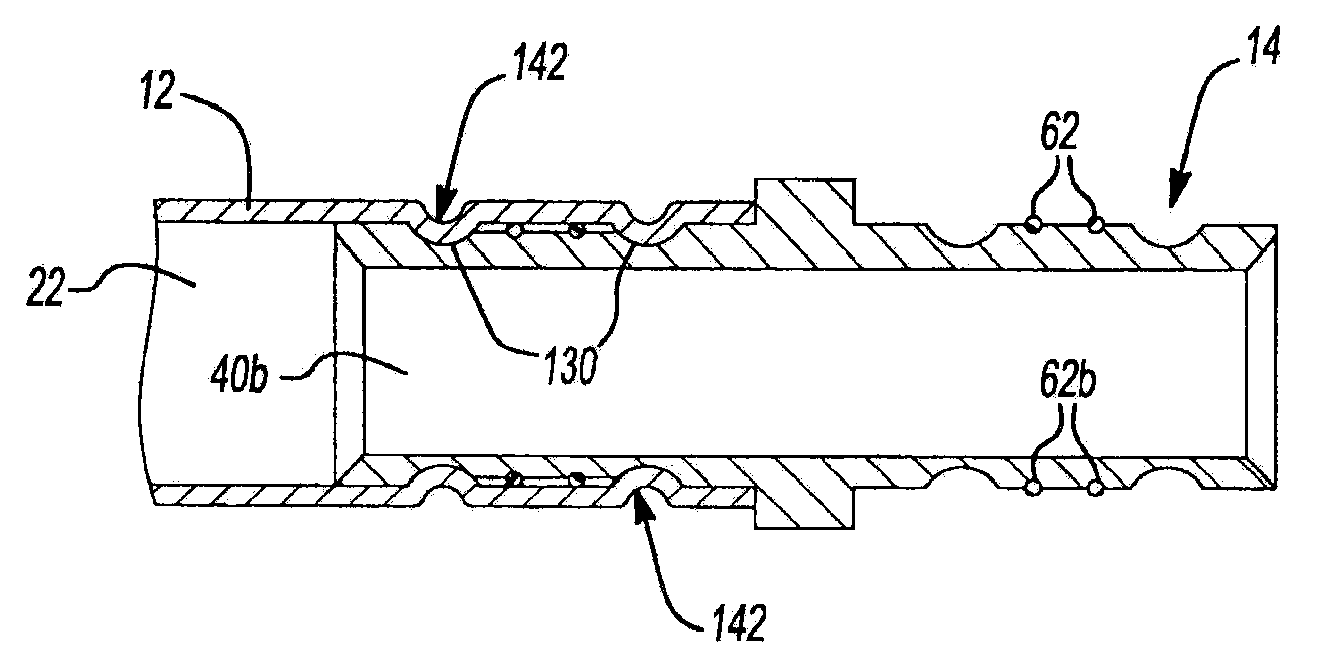

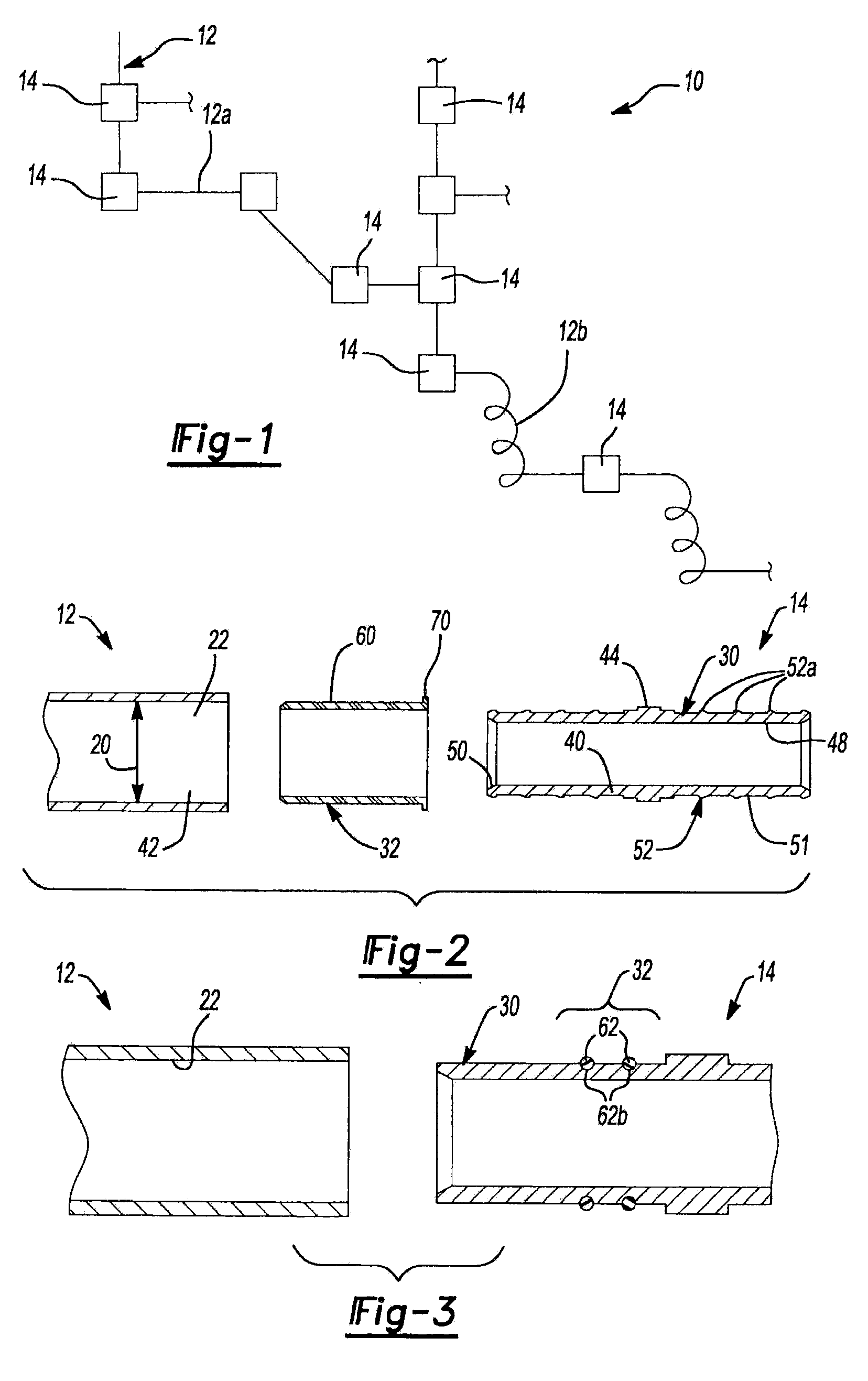

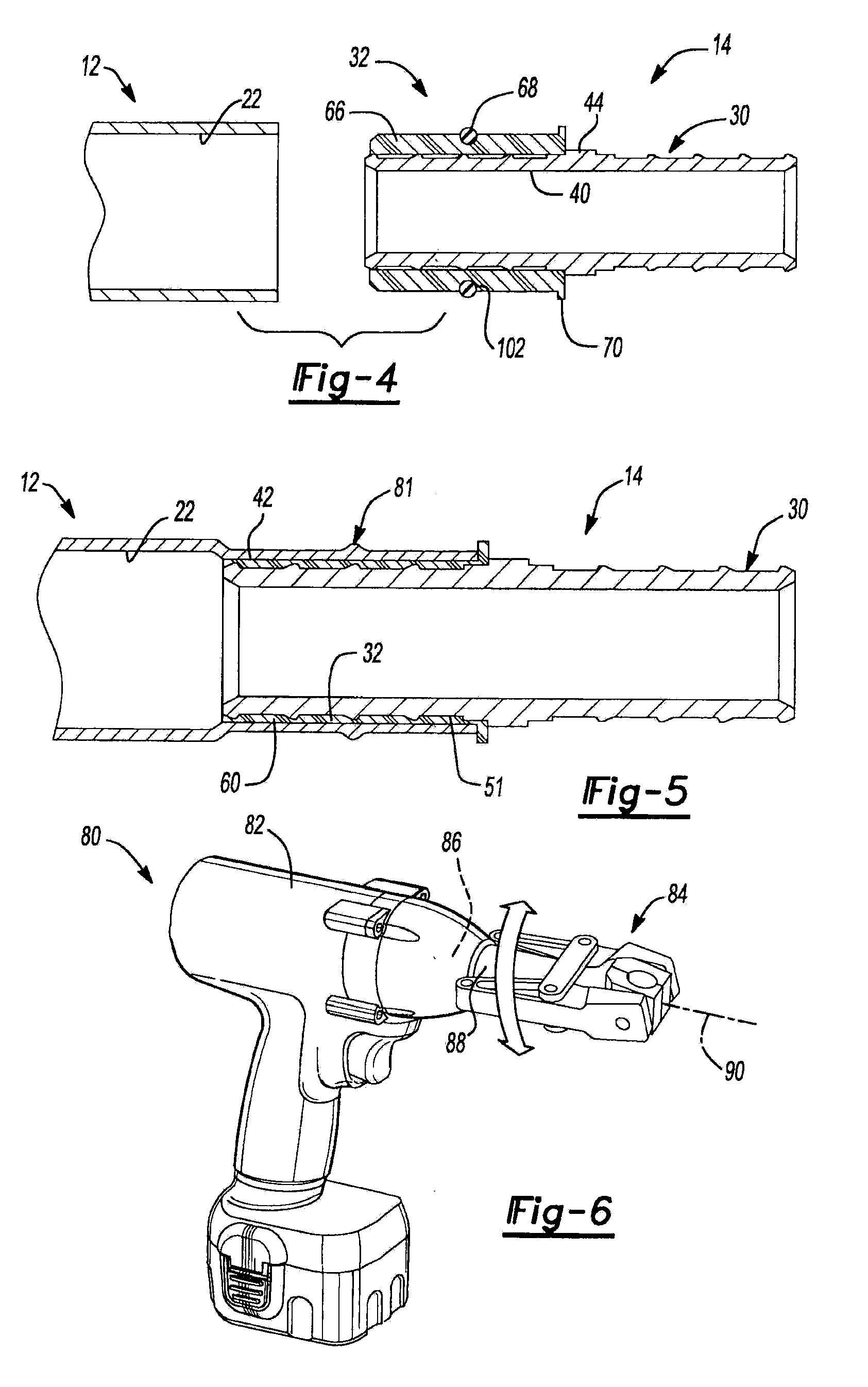

[0037] With reference to FIG. 1 of the drawings, an exemplary fluid conduit system constructed in accordance with the teachings of the present disclosure is generally indicated by reference numeral 10. The fluid conduit system 10 is illustrated to include a plurality of tubes 12 and a plurality of fittings 14 that are employed to join the tubes 12 to one another. In the example provided, the fluid conduit system 10 is employed to route and deliver potable water and as such, the tubes 12 may be constructed of copper and include conventional commercially available hard drawn tubing sticks 12a and conventional soft tubing 12b (also referred to herein as “annealed”, or “flexible metal” tubing) of the type that is commercially available in a coiled form from sources such as Mueller Industries, Inc. of Memphis, Tenn. Those skilled in the art will appreciate, however, that the tubes 12 may be made out of any suitable metal or plastic material and that the teachings of the present disclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com