Integrated pipe bender

A pipe bending machine and pipe fitting technology, which is applied in the field of pipe fitting flaring and pipe bending integrated pipe bending machine, can solve the problems of inconvenient pipe bending product promotion and use, difficult pipe bending processing and positioning, and increased processing procedures, so as to avoid uncertainty factor, production quality assurance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

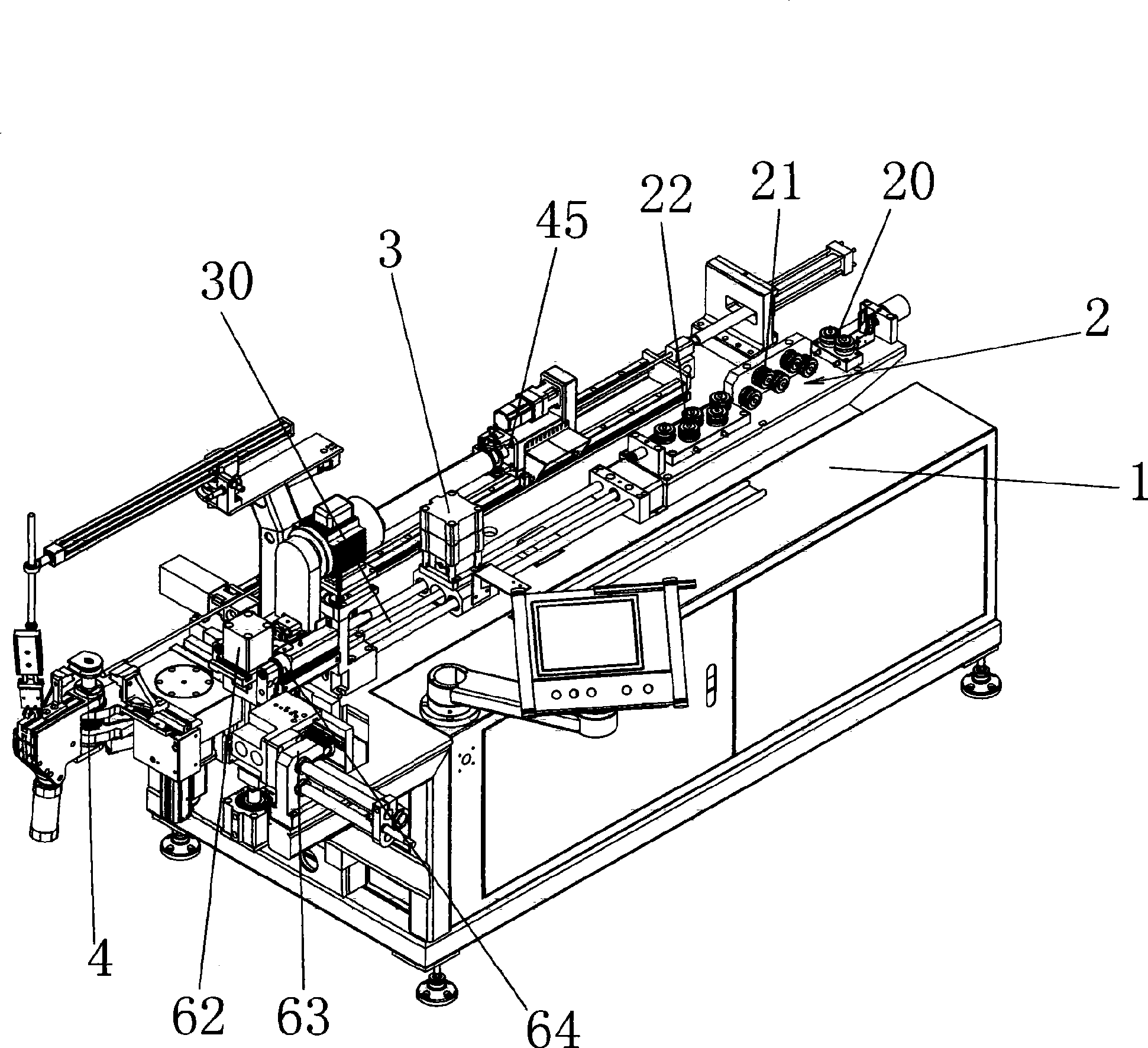

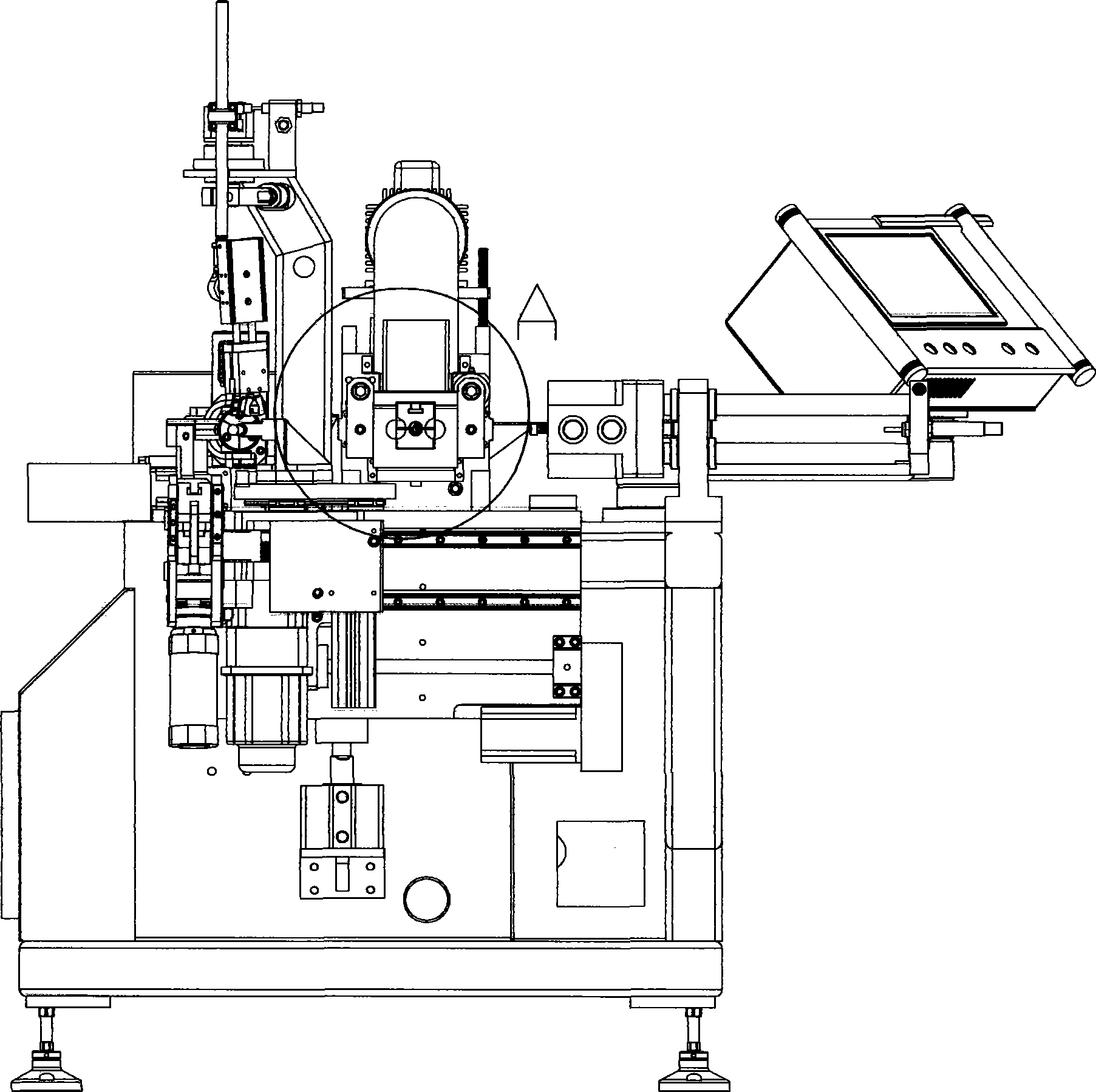

[0028] As shown in the figure, the integrated pipe bending machine includes an organic machine tool workbench 1, on which a pipe fitting straightening mechanism 2, a pipe fitting feeding structure 3 and a pipe bending forming mechanism 4 are sequentially installed. A material cutting device and a pipe head flaring device are also arranged between the pipe forming mechanisms 4 .

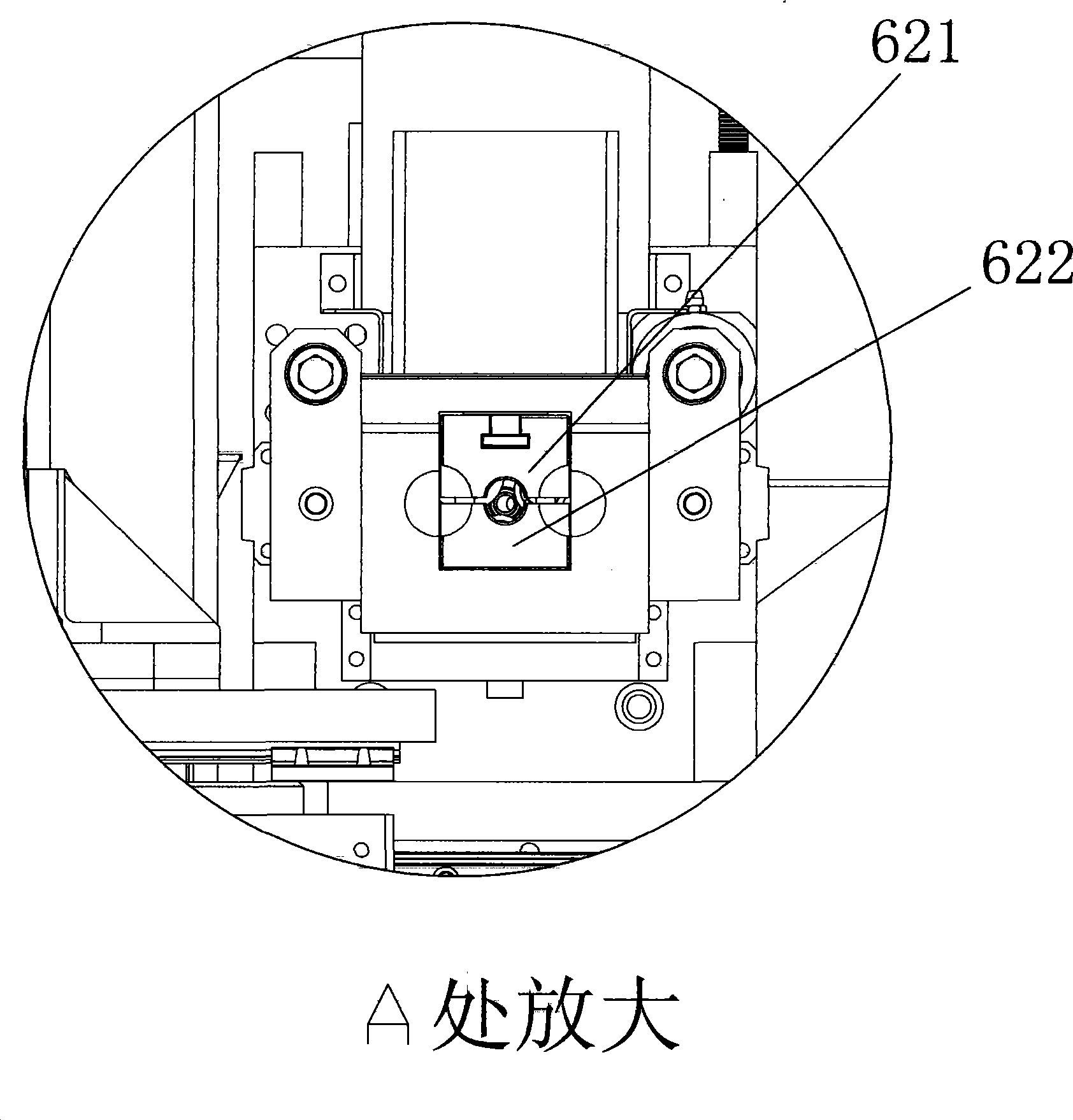

[0029] The cutting device includes a hollow rotating shaft 51 through which pipes pass, a cutting knife 52 mounted on the rotating shaft 51 and a control mechanism 53 for controlling the opening and closing of the cutting head. In the present invention, the rotating shaft 51 is driven by a motor. The pipe head flaring device includes a flaring punch 61 that can move in translation, a flaring clamping die mechanism 62 and a driving mechanism 63 that drives the flaring pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com