Switch terminal processing method and processing device thereof

A technology of switch terminals and processing equipment, which is applied in the direction of electric switches, contact parts manufacturing, electrical components, etc., can solve the problems of narrow center mold space, limited number of installed tools, and difficulty in center mold design, so as to achieve sufficient action space, The effect of improving work efficiency and product quality and reducing the cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the features of the technical solution of the present invention, the technical solution of the present invention will be further described in detail below through specific implementation manners and in conjunction with the accompanying drawings.

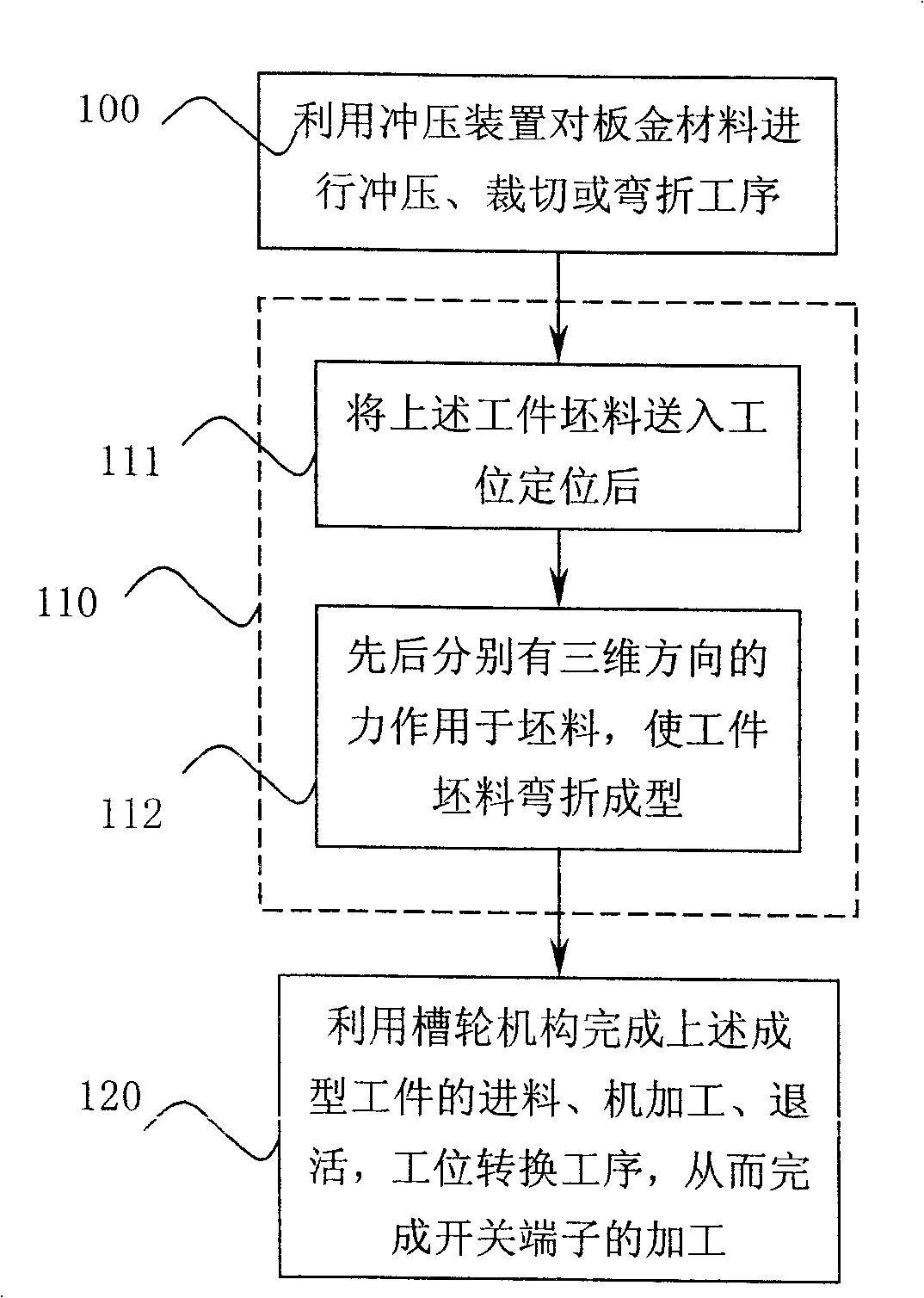

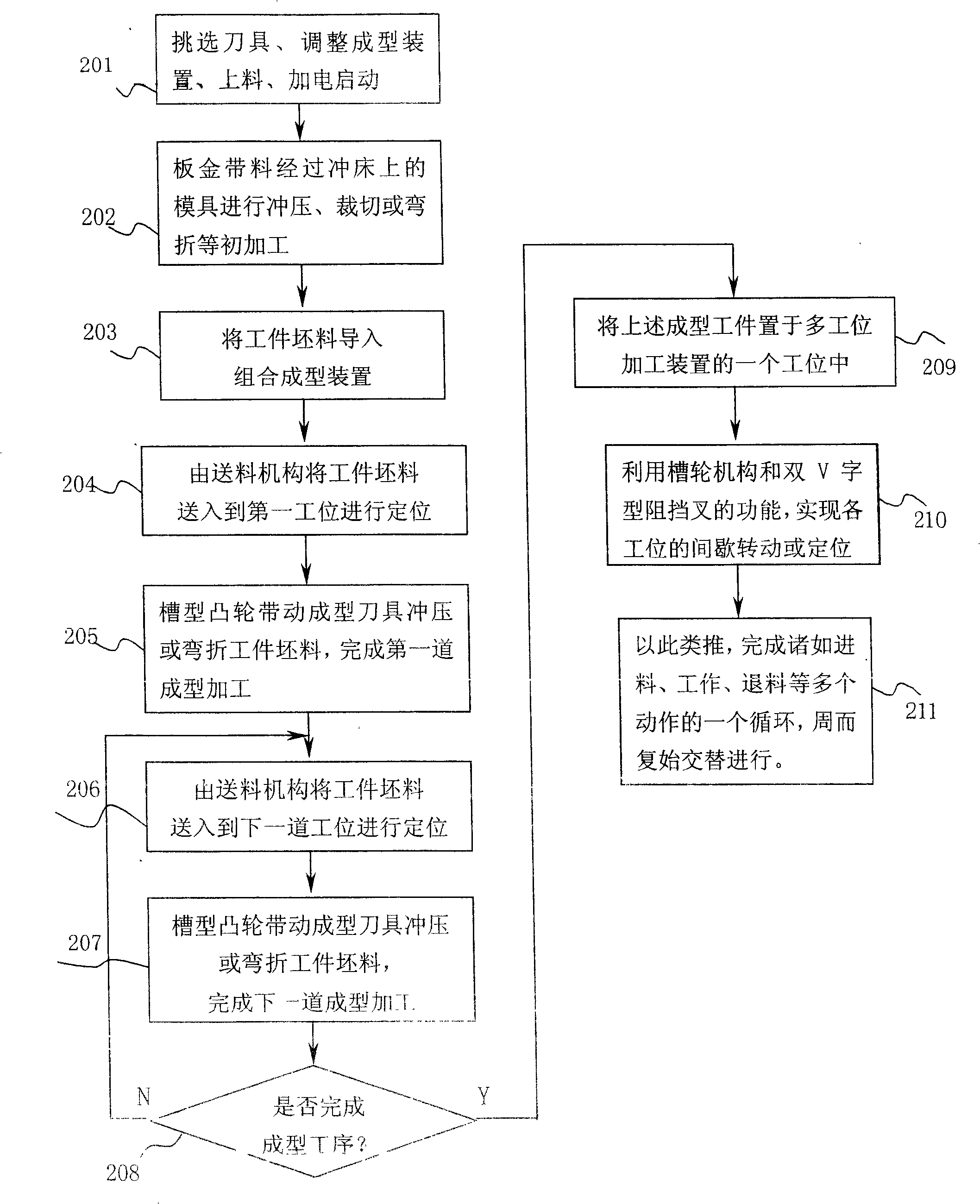

[0032] Such as Picture 1-1 As shown, the processing method of the switch terminal of the present invention mainly includes the following three steps: stamping and cutting step 100, that is: using a stamping device to stamp, cut or bend the sheet metal material; forming step 110, that is: first, The above-mentioned workpiece blank is sent to the station for positioning 111, and three-dimensional force acts on the blank one after another, so that the workpiece blank is bent and formed 112, and the three-dimensional direction force is respectively moved by a plurality of forming tools in the guide rails in their respective directions And it is produced by crimping with the surface of the workpiece b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com