Continuous casting entity simulation and virtualization realization platform

A technology of physical simulation and continuous casting, which is applied in the field of continuous casting physical simulation system and virtual realization platform, can solve the problem of inability to provide virtual design, virtual production, virtual training and virtual maintenance, no establishment of virtual continuous casting production line, and lack of production process control simulation and other issues to achieve the effects of shortening the development cycle, strong intuitiveness, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

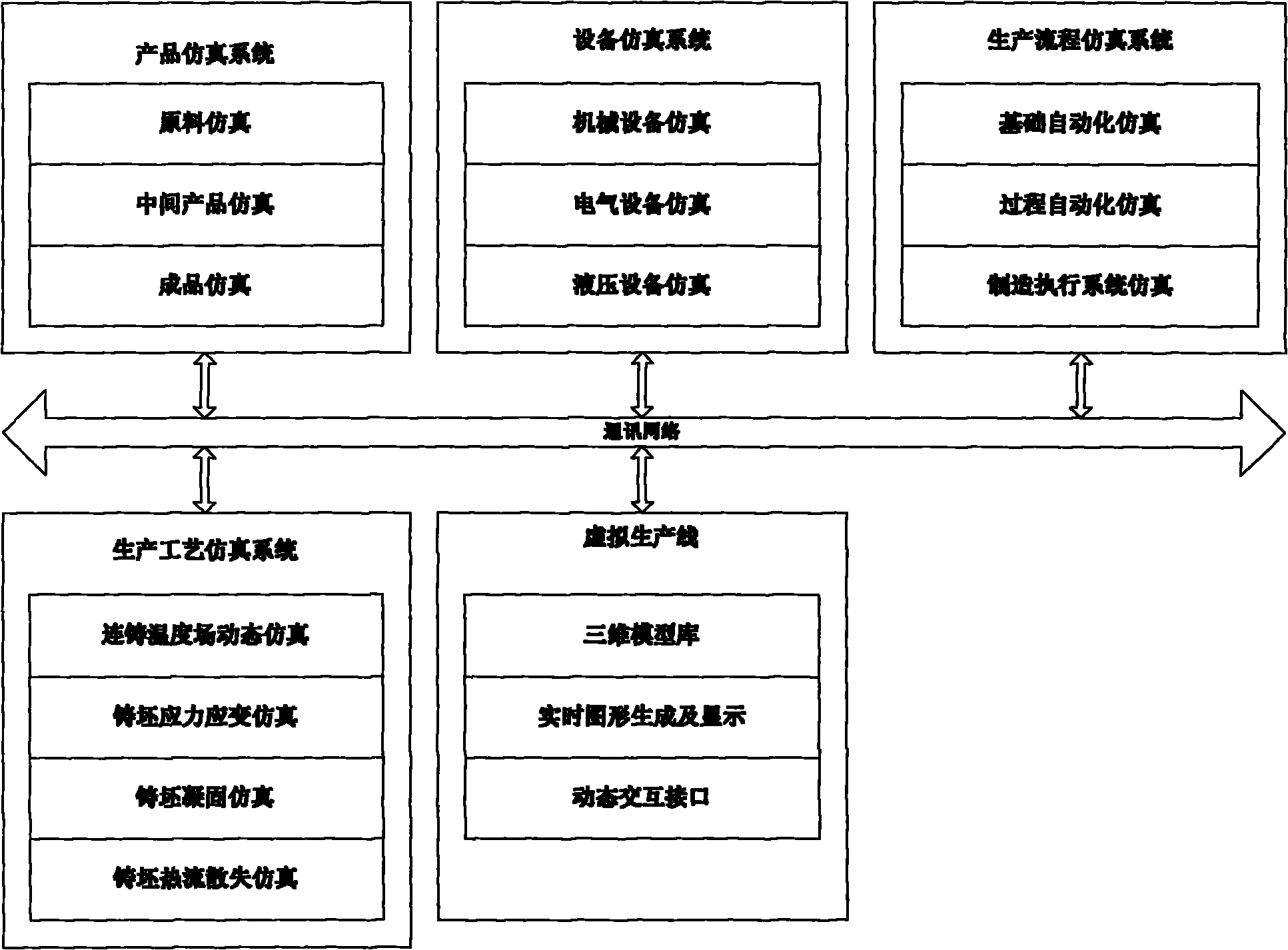

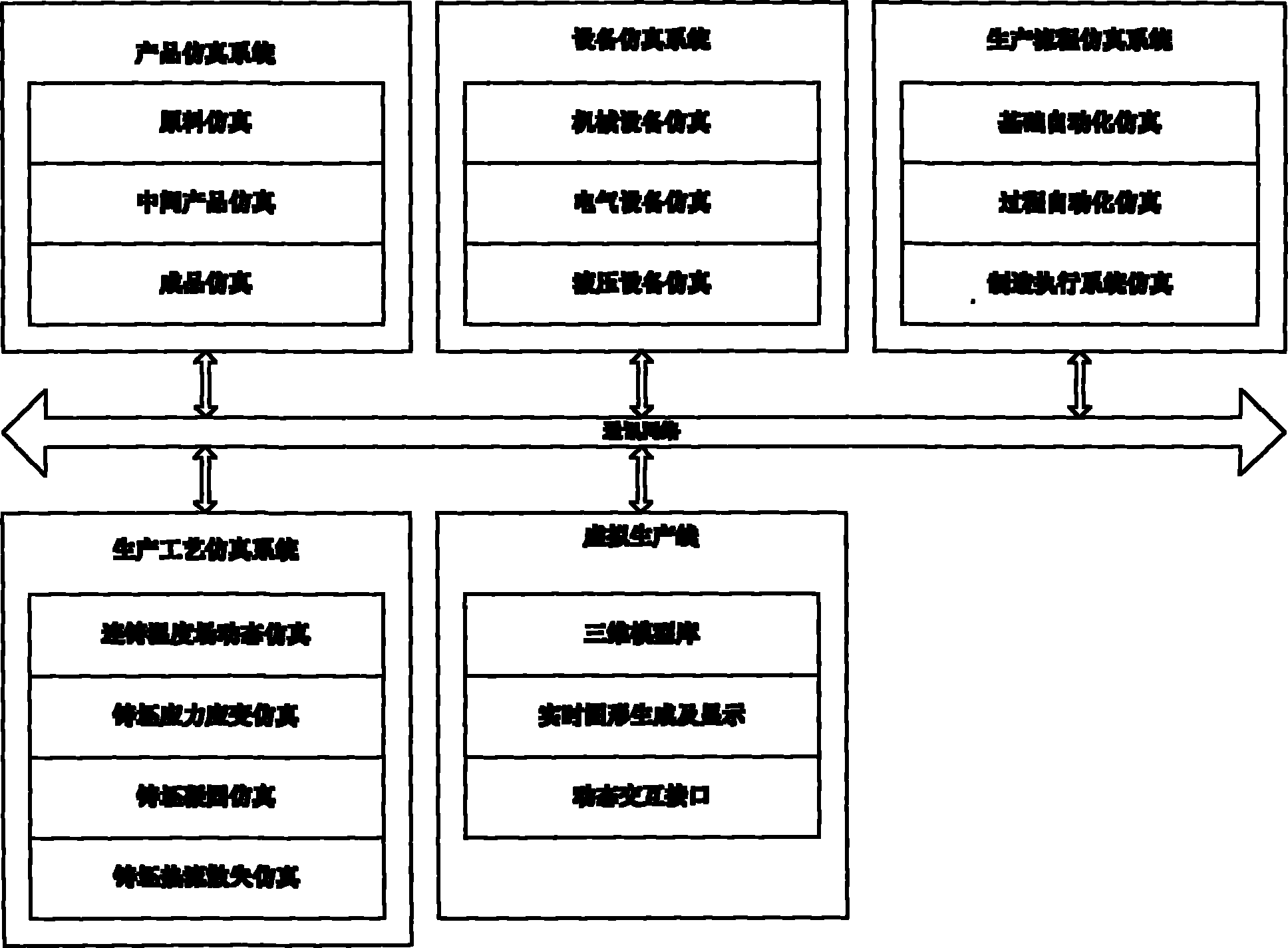

[0018] Embodiment 1: as figure 1 Described: a continuous casting entity simulation system, which includes a production process simulation system connected to a communication network, an equipment simulation system, a product simulation system and a production process control simulation system; wherein the production process simulation system is used for continuous casting production process The simulation of equipment; the equipment simulation system is used to simulate the mechanical, electrical and hydraulic equipment involved in production; the product simulation system is used to simulate raw materials, intermediate products and finished products; the production process simulation system is used to control the process of continuous casting production process Simulation.

[0019] The production process simulation system includes:

[0020] Continuous casting temperature field dynamic simulation module: use the numerical simulation based on the solidification heat transfer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com