Module capacity measurement system and module capacity measurement method

A measurement system and capacity test technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of module test compatibility and low test efficiency, prone to subjective errors, relying on manual operation, etc., to improve safety Sex and efficiency, lower quality requirements, fast and compatible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In order to solve the technical problems existing in the prior art, an embodiment of the present invention provides a module capacity measurement system.

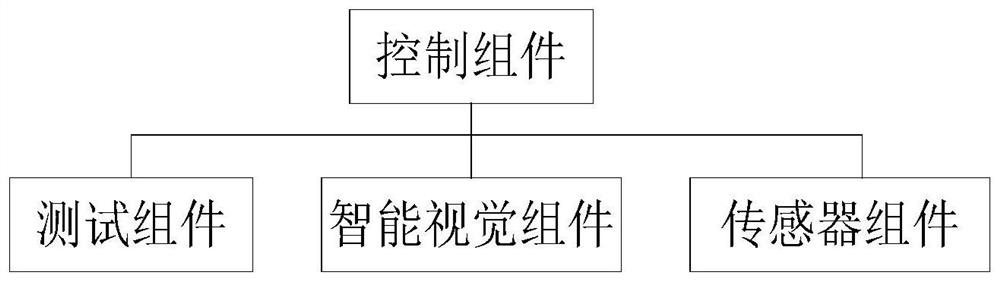

[0040] figure 1 A schematic structural diagram of a module capacity measurement system according to an embodiment of the present invention is shown; refer to figure 1 As shown, the module capacity measurement system according to the embodiment of the present invention includes a test component, an intelligent vision component, a sensor component and a control component, wherein the control component is respectively connected to the pre-test component, the intelligent vision component and the sensor component.

[0041] Among them, the test component is mainly used to fix the module to be tested during the module capacity measurement process, and in the measurement stage, based on the charge-discharge control signal, the capacity test is performed on the module to be tested that has been connected in series to obtain c...

Embodiment 2

[0059] In order to solve the technical problems existing in the prior art, an embodiment of the present invention provides a method for measuring the capacity of a module. The module capacity measurement method in this embodiment is implemented on the basis of the module capacity measurement system disclosed in the first embodiment.

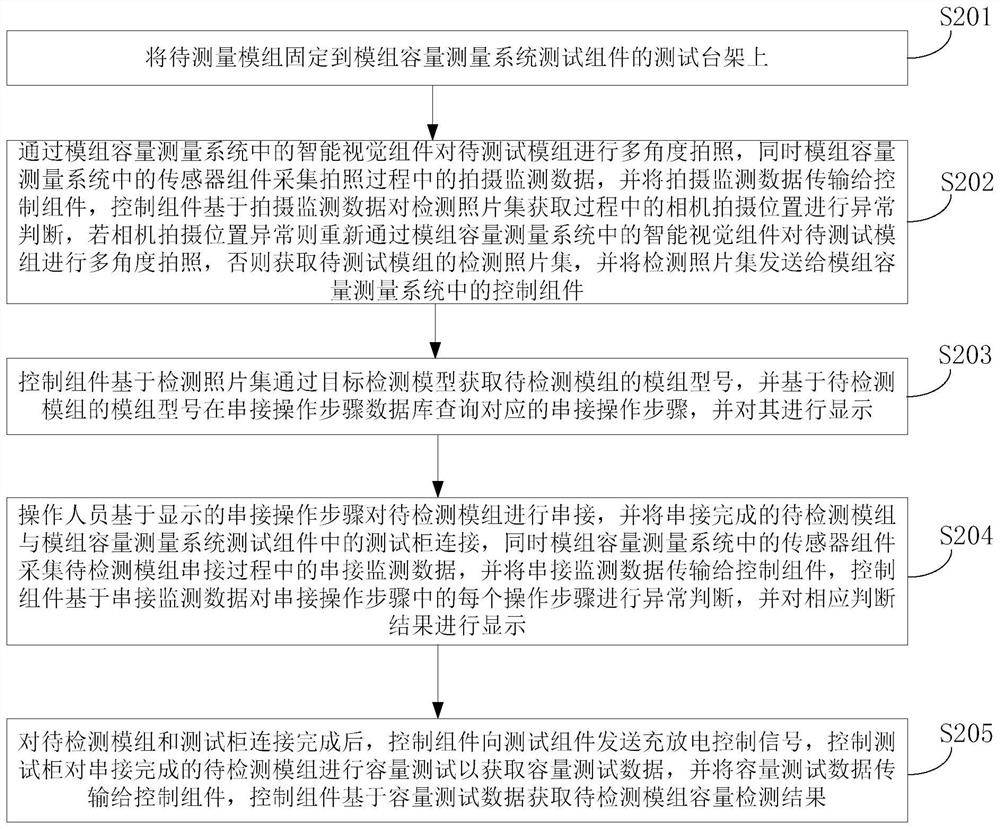

[0060] figure 2 A schematic flowchart of the method for measuring the capacity of a module according to the second embodiment of the present invention is shown. Referring to Embodiment 2, the method for measuring the capacity of a module according to an embodiment of the present invention includes the following steps.

[0061] In step S201, the module to be measured is fixed on the test bench of the test component of the module capacity measurement system.

[0062] Specifically, the module to be tested is fixed on the test bench of the test component in the module capacity measurement system by the fixing member on the test bench.

[0063] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com