Hydraulic equipment for hot-rolled member scale removal

A descaling equipment and equipment technology, applied in the direction of workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve the problems of insufficient descaling, no descaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

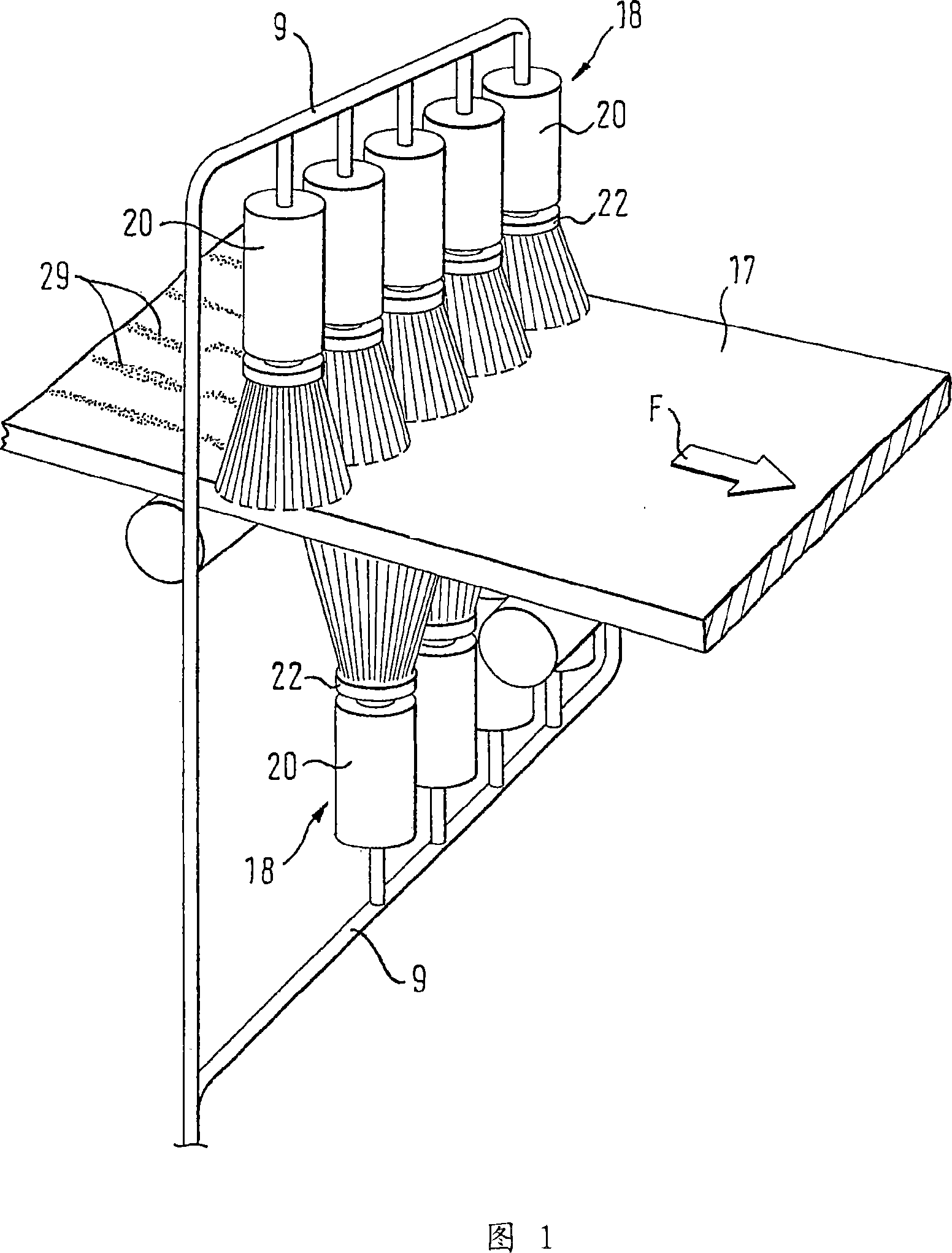

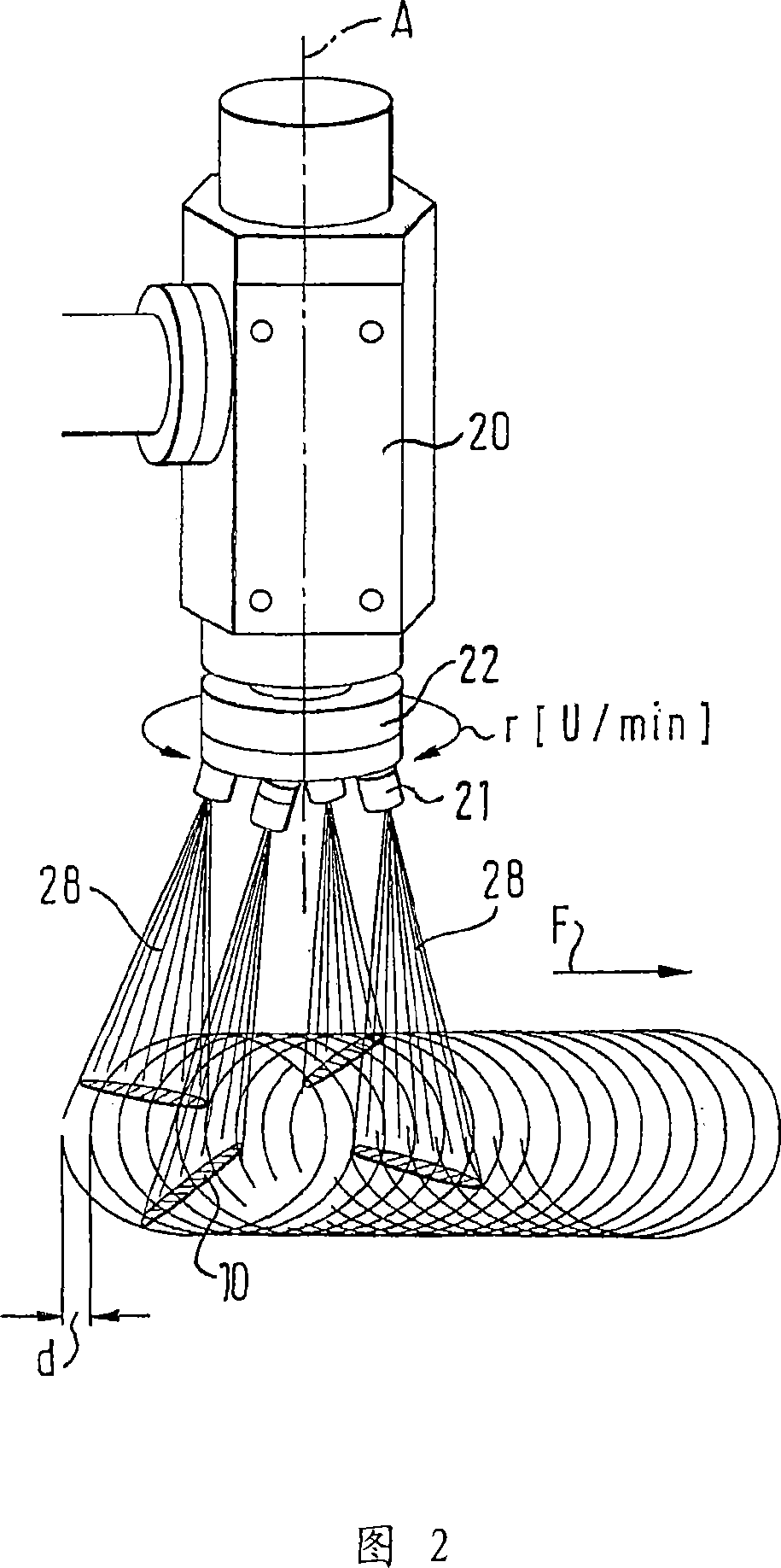

[0017] The rolling stock descaling plant shown in FIG. 1 comprises two rows 18 each comprising five stationary nozzle heads 20 and extending transversely in the direction of movement F on each side of the rolling stock 17 . Figure 2 shows one of the nozzle heads in detail. At its periphery, each nozzle head 20 is provided with four flat-bottomed nozzles 21 arranged on its periphery and mounted on a ring 22 of this nozzle head 20, which ring 22 is adapted to be driven in rotation. The nozzle is supplied with pressurized water via pipe 9 at a pressure of 300 to 1000 bar.

[0018] The ring 22 is driven at a rotational speed of 200 to 1000 r.p.m.

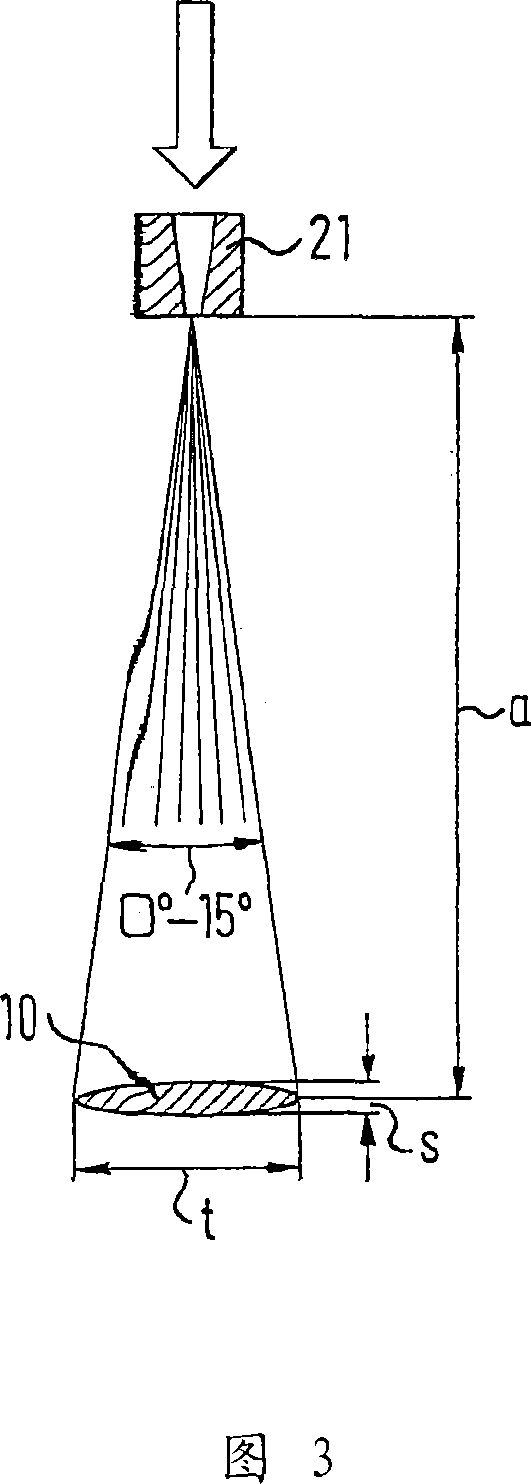

[0019] The nozzle head 20 is arranged so that the surface of the workpiece is at a distance a from the nozzle 21 and the workpiece moves in the direction of the arrow F below the stationary row of nozzle heads. As shown in FIG. 3 , this distance is chosen so that the length t of the major major axis and the length s of the minor major...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com