Runway switch laying method for ballast track passenger special line

A technology for passenger dedicated lines and laying methods, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of insufficient compactness, affecting the use of turnouts, deformation, etc., and achieve the effects of ensuring geometric dimensions, improving adjustment accuracy, and easy control of elevation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment operates as follows:

[0032] 1. Line pre-laying

[0033] Temporary short rows of pre-paved alternative lines are used within the range of turnouts, and engineering trains pass through the pre-paved alternative lines, and then the lines within the range of turnouts are maintained according to the "five pounding and three stabilizing" procedures, so that the density of the track bed reaches Require;

[0034] 2. Remove the short row and set up the turnout assembly platform

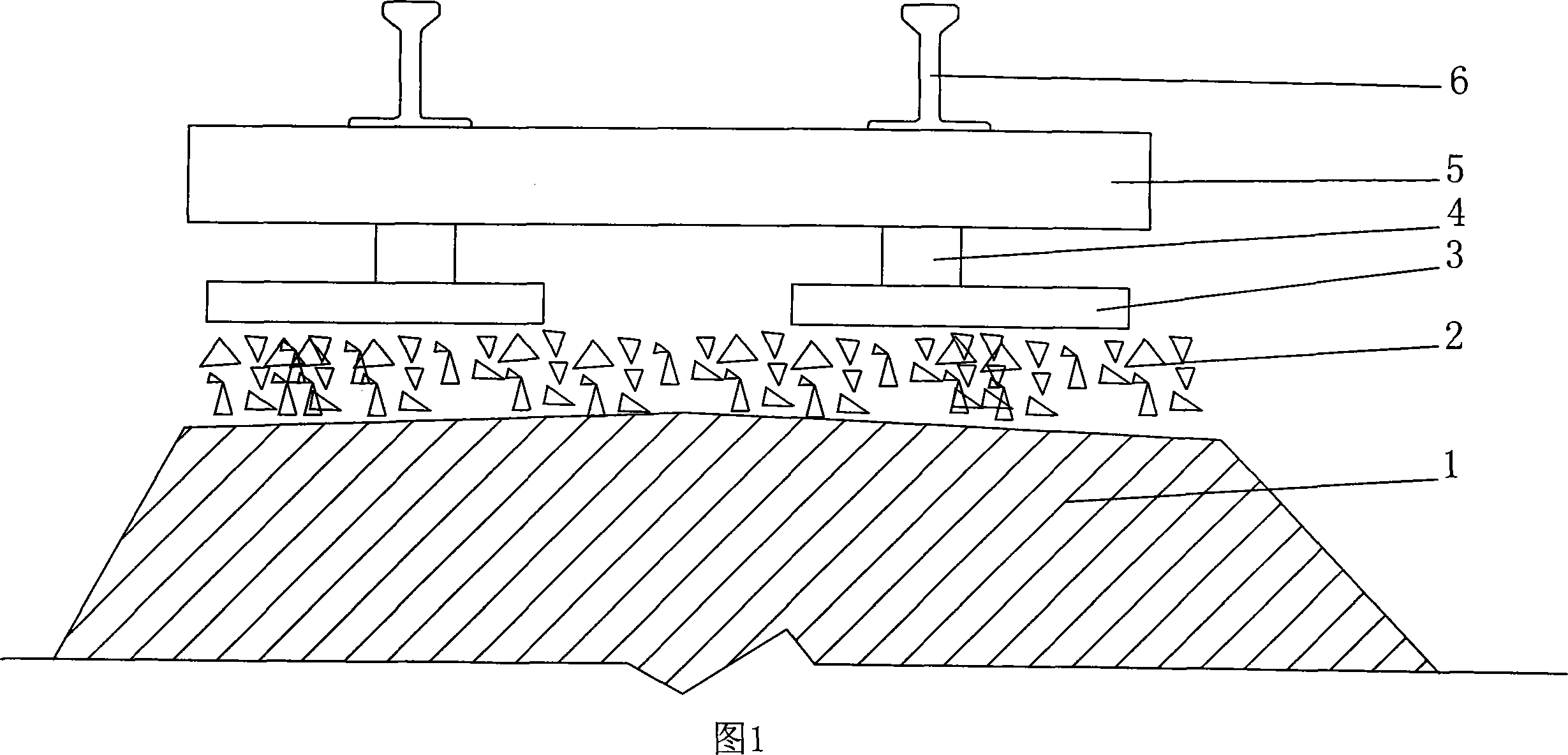

[0035] Referring to Figure 1, first use a crane to dismantle the short row, and then spread the ballast 2 on the basic road body 1 to level the ballast bed so that the elevation of the ballast bed is 10cm lower than the bottom of the sleeper, and tamp the ballast bed so that the density reaches 1.7g / cm 3 , 3m straight ruler to detect ballast flatness is not less than 10mm.

[0036] At the position of each sleeper, place a 5cm high skid 3, the length of the skid 3 is 400mm, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com