Fully automatic numerical control drill cutter grinding machine

A drill sharpening and fully automatic technology, which is applied to boring machine/drilling machine parts, drilling tool accessories, drilling/drilling equipment, etc. Unable to guarantee and other problems, to achieve the effects of strong rigidity, improved processing efficiency, and less consumption of grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

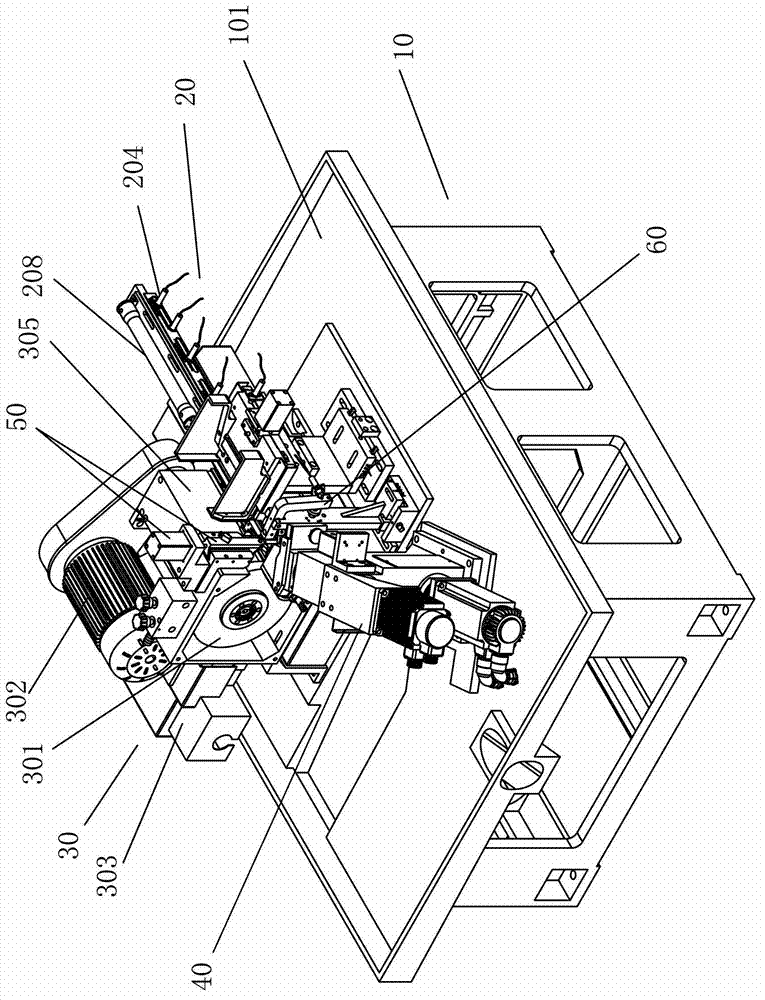

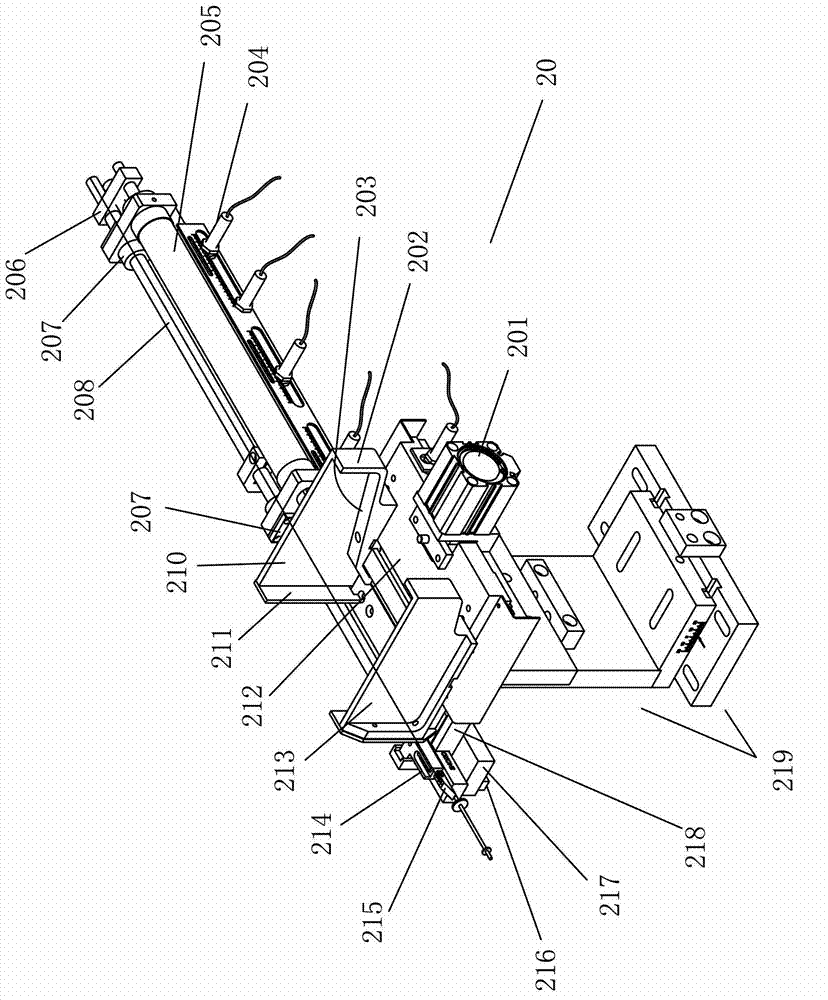

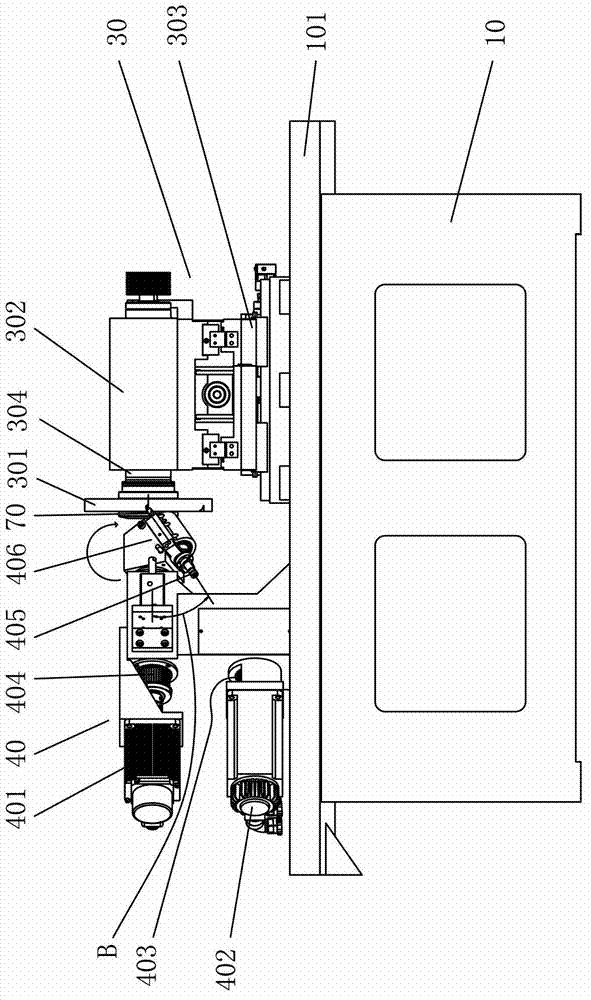

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -7:

[0026] Fully automatic CNC drill sharpening machine, one side of the workbench 101 set on the upper part of the integrally cast bed base 10 is equipped with a grinding assembly 30, and the grinding assembly 30 includes a cross support that can be displaced in X and Y directions driven by a power device Plate 303, a grinding head seat 305 is installed on the cross support plate 303, a high-speed grinding head main shaft 304 is arranged on the grinding head seat 305, a grinding wheel 301 is installed on the inner end of the high-speed grinding head main shaft 304, and a high-speed grinding wheel driven by a transmission device is installed on the outer end. The frequency conversion motor 302 that the grinding head main shaft 304 rotates, the workbench on one side of the grinding wheel 301 is provided with a dual-power-driven dual-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com