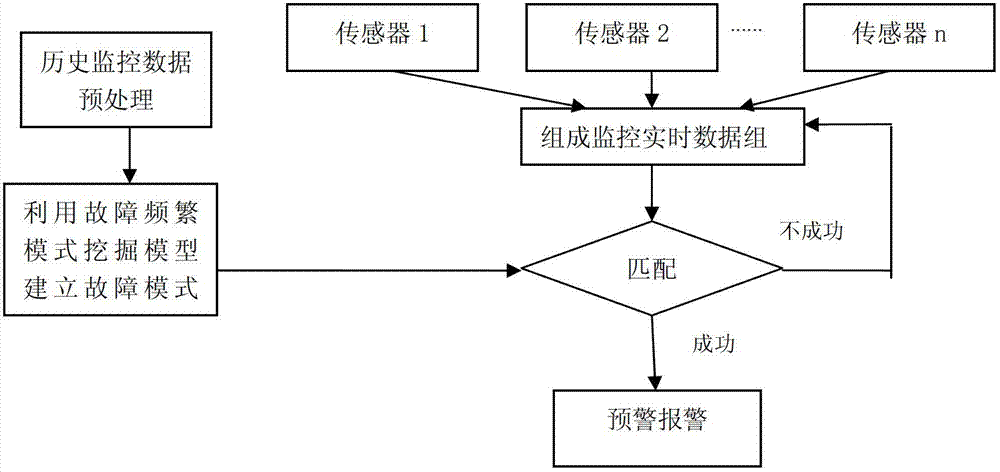

Fault early warning method for hydraulic equipment based on fault frequent pattern

A frequent mode and fault warning technology, applied in electrical testing/monitoring, etc., can solve problems such as long mining time, false positives and omissions of invalid rules, and achieve the goal of reducing computational complexity, reducing the number of links, and reducing the rate of false positives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

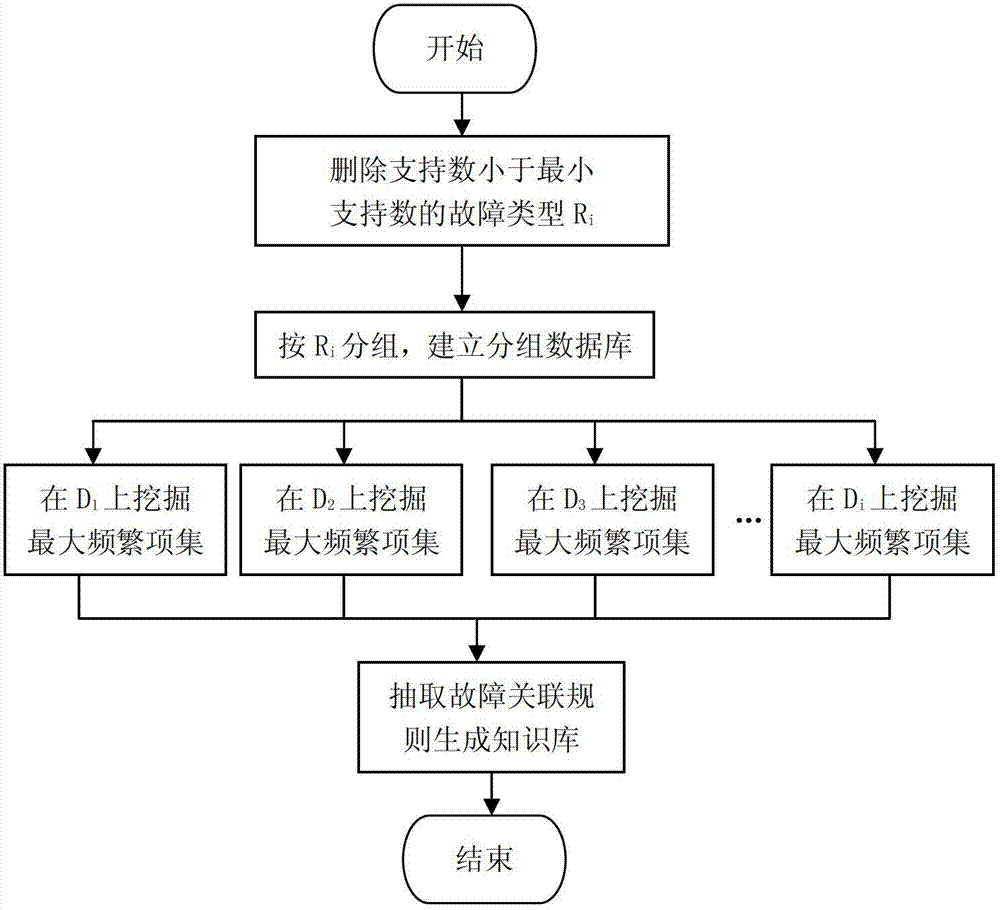

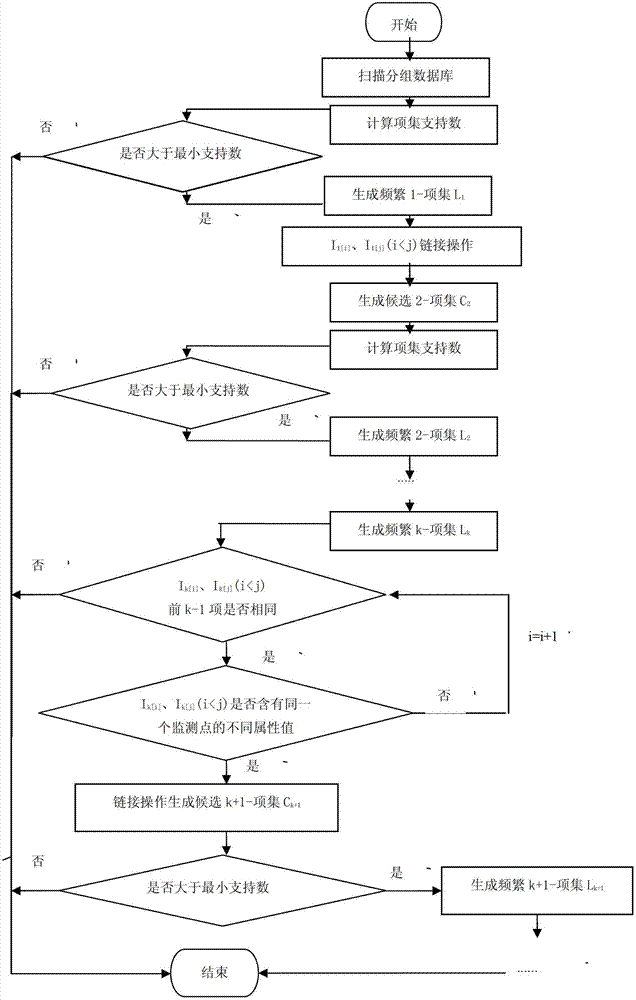

Method used

Image

Examples

Embodiment

[0104] In order to further verify the effectiveness of the hydraulic equipment failure early warning method based on the frequent failure mode, the monitoring data of the hydraulic unit of a large steel mill in China were mined. Firstly, data preprocessing is carried out, including data cleaning, empty value data filling, etc.; experts and engineers jointly determine the threshold value of each indicator, and convert continuous real numbers into discrete values; establish a fault mining library D and three test libraries S 1 , S 2 , S 3 , has the following characteristics:

[0105] 1. Fault mining database D contains 300 fault information, including 19 fault types;

[0106] 2. Test library S 1 Contains 150 pieces of monitoring data, including 120 pieces of normal operation data and 30 pieces of fault data;

[0107] 3. Test library S 2 Contains 300 pieces of monitoring data, including 220 pieces of normal operation data and 80 pieces of fault data;

[0108] 4. Test librar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com