Motor stator coil shaping machine

A technology of motor stator and shaping machine, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of easily damaged copper wire protection layer of coils, economic losses, waste, etc., so as to avoid transfer accidents and improve work efficiency. Efficiency and the effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

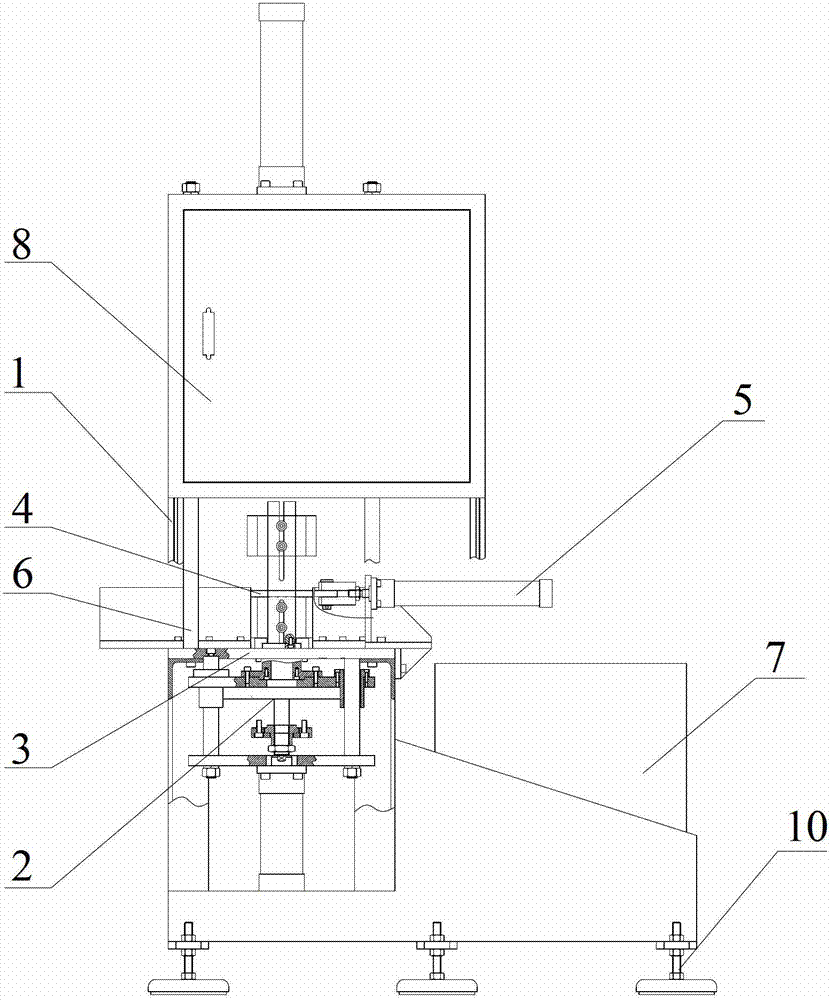

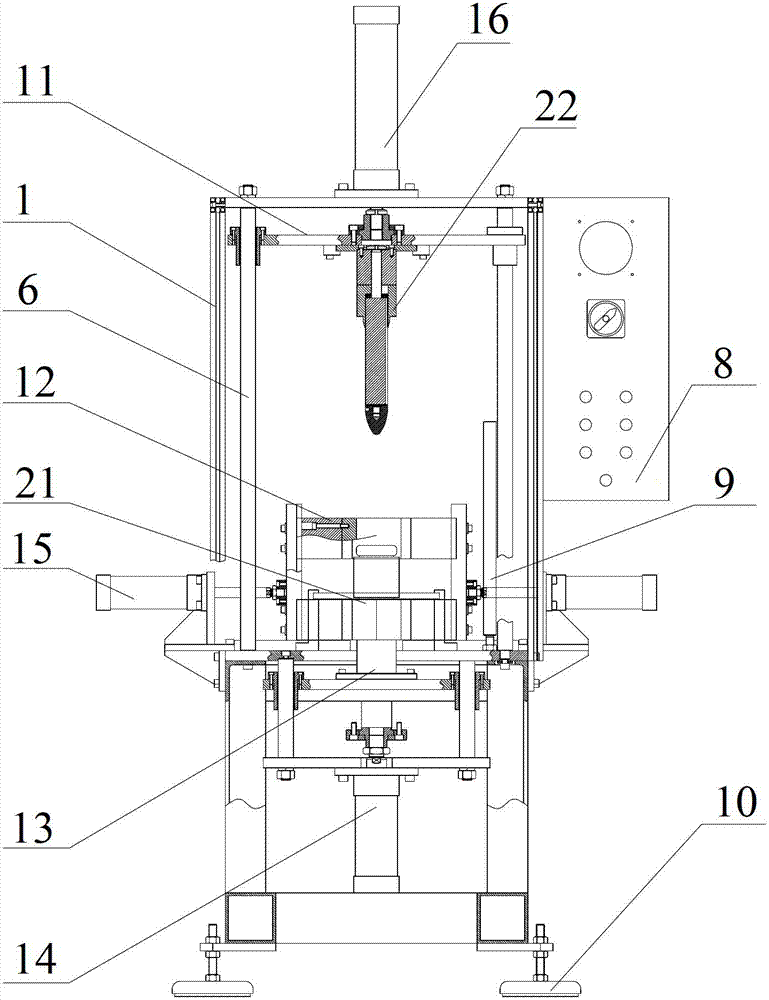

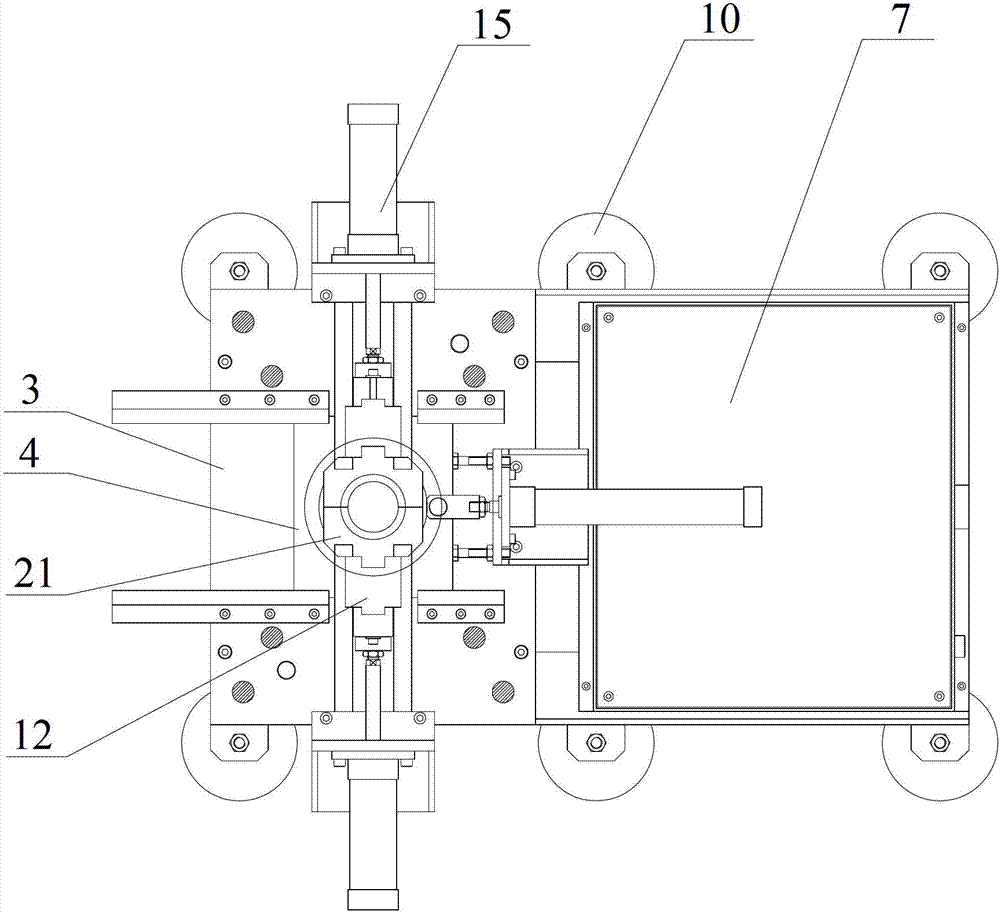

[0017] Please refer to the attached Figure 1 to Figure 5 , the embodiment of the present invention includes:

[0018] A motor stator coil shaping machine, comprising: a frame 1, support feet 10, a control box 8 and a hydraulic equipment box 7; a vertical sliding guide post 6 is arranged on a workbench 3 in the middle of the frame 1; The workbench 3 is equipped with a light rail sliding plate 4 driven by a hydraulic cylinder I5; the light rail sliding plate 4 can work with the radial shaping device 2 above it; the radial shaping device 2 includes: a shaping half that fits the shape of the motor coil A mold 21 and a shaping mandrel 22 for auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com