Quasi-isostatic pressing vacuum hydraulic machine

A quasi-isostatic hydraulic press technology, applied in the field of hydraulic equipment, can solve the problems of lack of air extraction function and difficult structural design of quasi-isostatic hydraulic press, and achieve the effect of convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The quasi-isostatic vacuum hydraulic machine disclosed in this embodiment includes a main body, a hydraulic transmission system, a vacuum system and an electrical control system.

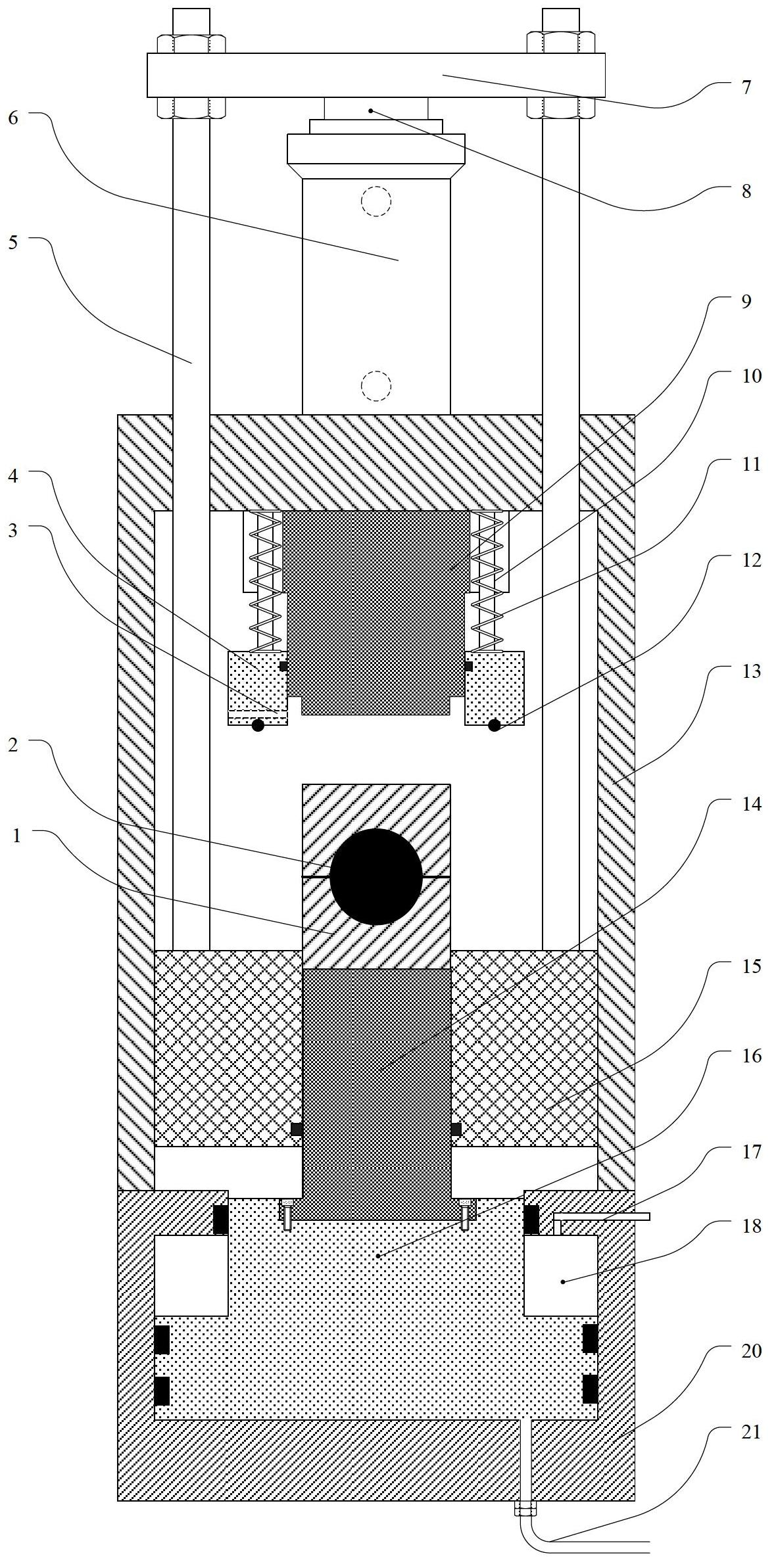

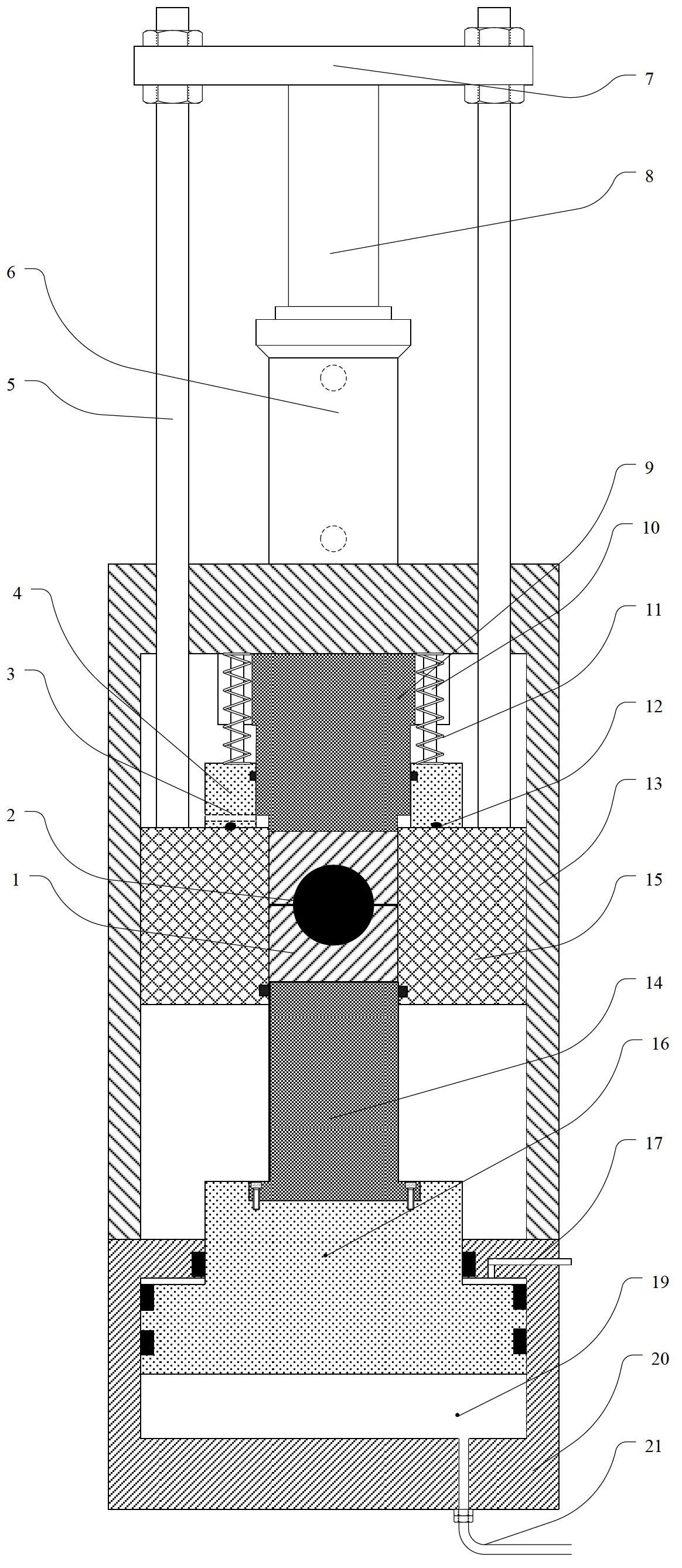

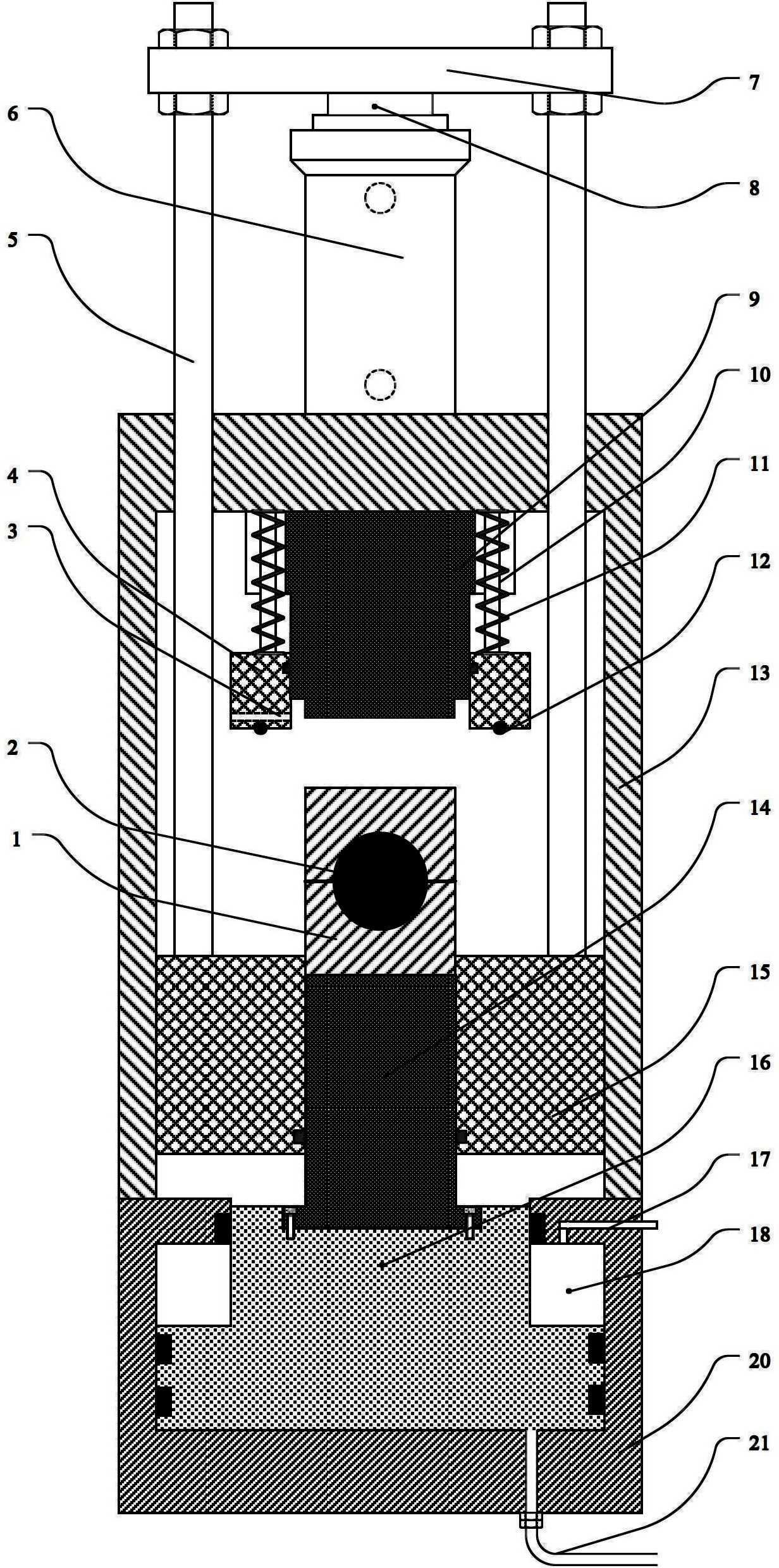

[0026] Such as figure 1 with figure 2 As shown, the main body mainly includes the fuselage 13, the lower main hydraulic cylinder 20, the upper auxiliary hydraulic cylinder 6, the upper punch 9, the lower punch 14, the vacuum cover 4 and the steel mold cylinder 15, all of which are on the same axis heart line.

[0027] The fuselage 13 is the part for pressing and operating, and is fastened on the lower main hydraulic cylinder 20 by screws or other means to form a closed rigid integral frame. Fuselage 13 The body is a cavity with an operation window on the side, and the shape is preferably cylindrical. The upper punch 9, the lower punch 14, the vacuum cover 4 and the steel mold barrel 15 are all installed inside the body 13 cavity. The lower punch 14 is fixed on the upper end of the main h...

Embodiment 2

[0032] When the vacuum hydraulic press described in Embodiment 1 of the present invention works, it operates as follows:

[0033] Place the rubber mold 1 equipped with the prepared powder 2 on the lower punch 14;

[0034] The auxiliary hydraulic cylinder 6 works, the piston rod 7 goes up, and the steel mold cylinder 15 is driven up by the load beam 8 and the guide rod 5 until it is closely attached to the vacuum cover 4;

[0035] The vacuum system is opened, and the space formed by the vacuum cover 4, the upper punch 9, the lower punch 14, and the steel mold cylinder 15 is vacuumed through the air extraction hole 3;

[0036] When the vacuum degree reaches the set value, the main hydraulic cylinder 20 works, and the hydraulic system injects hydraulic oil into the lower chamber 19 of the main hydraulic cylinder through the oil pipe 21 in the lower chamber of the main hydraulic cylinder, so that the piston 16 of the main hydraulic cylinder drives the lower punch 14 to move upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com