Multi-specification combined elbow welding tool and welding method for same

A multi-specification, welding tooling technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of the size and angle of the finished elbow, difficult to control, low qualification rate, and large deviation of the size of the head, so as to improve the quality of the finished product. Quality and production efficiency, the effect of solving positioning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0029] Such as Figure 5 and Figure 6 The ceramic composite elbow shown is a common 90° composite elbow. The actual production is to process it into a single piece of 15° elbow, and then burn the ceramic layer on the inner layer of the 15° single piece elbow, and then carry out Splicing and assembly welding, K is the weld between the single-piece elbow pieces, 6-piece welding is a 90° elbow, and finally the flange is welded at both ends of the elbow to become the final product, and M is the connection between the elbow piece and the joint. Welds between flanges.

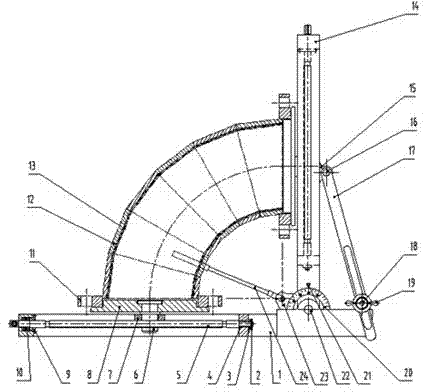

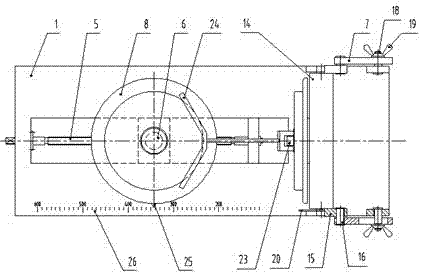

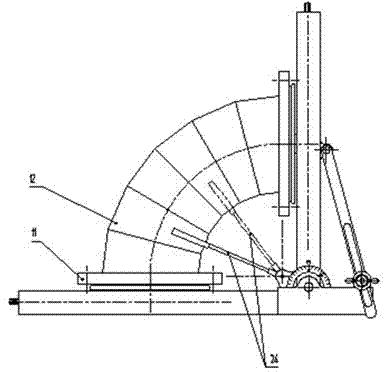

[0030] Such as figure 1 and figure 2 Shown are the front view and top view of the multi-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com