Method and equipment for disassembling circuit board using contacted impact

A circuit board and contact technology, which is applied in the field of circuit board disassembly and equipment using contact impact, can solve the problem of inability to disassemble inserted components, time-consuming and laborious preparation for disassembly, and poor disassembly of inserted components. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Example 1 According to Method 1, the circuit board with components on one side is disassembled

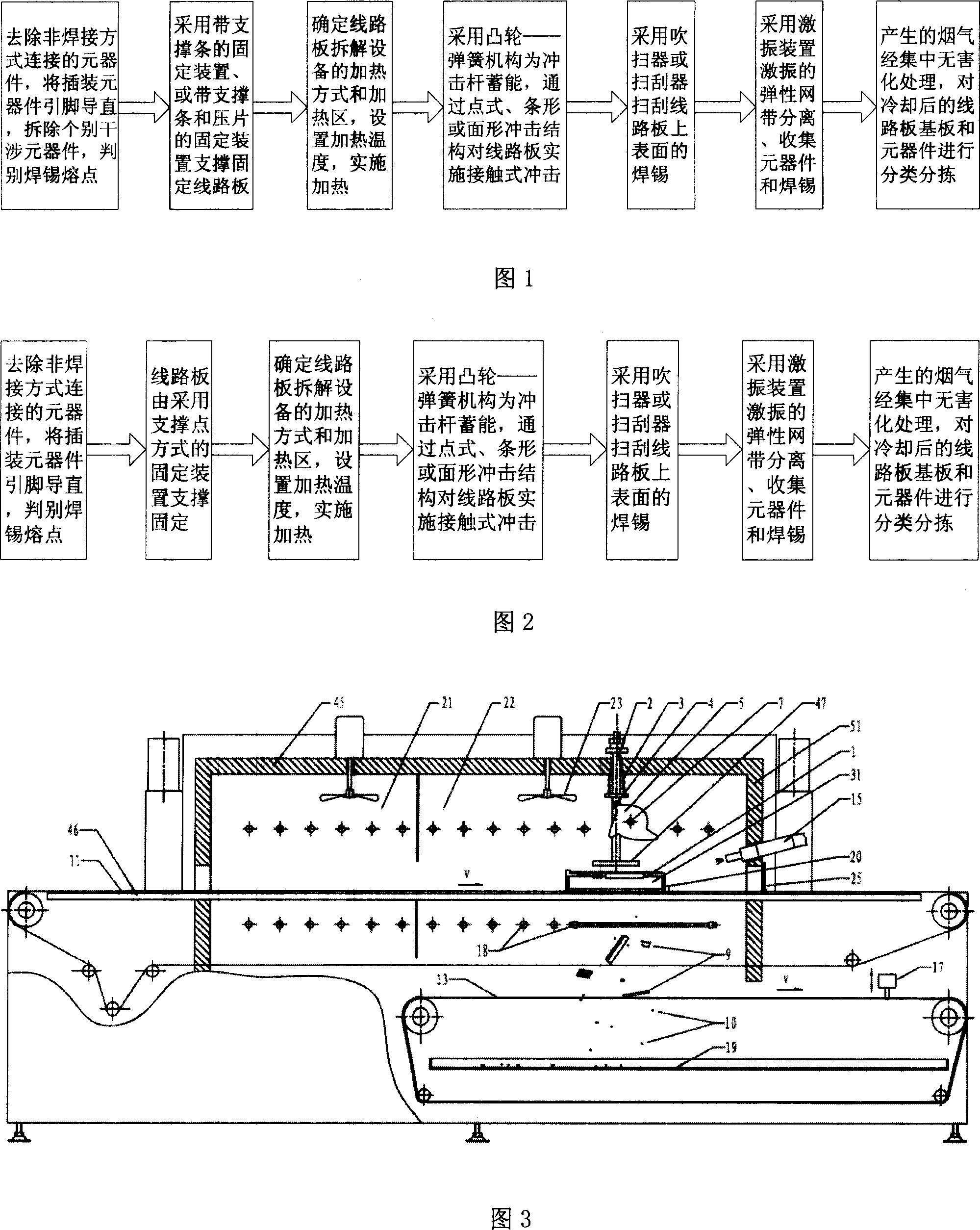

[0109] Fig. 1 is a flow chart of method 1 of the present invention. A method for dismantling a circuit board by contact impact, the method includes the following steps:

[0110] 1) Take a piece of waste circuit board with components on one side (hereinafter referred to as circuit board), such as a computer motherboard, and clean the circuit board to remove dust and dirt; Direct the pins of the plug-in components to be removed on the circuit board so that they are basically perpendicular to the circuit board substrate; roughly determine the solder (solder paste) used for the circuit board according to the type of circuit board substrate and the type of components ) melting point temperature; take the two opposite sides with the shortest distance between the opposite sides of the circuit board, and desolder and remove individual components on the circuit board, so that each s...

Embodiment 2

[0118] Example 2 According to the second method, the circuit board with components on one side is disassembled

[0119] Fig. 2 is a flow chart of the second method of the present invention. A method for dismantling a circuit board by contact impact, the method includes the following steps:

[0120] 1) Take a piece of waste circuit board with components on one side (hereinafter referred to as circuit board), such as a computer motherboard, and clean the circuit board to remove dust and dirt; Direct the pins of the plug-in components to be removed on the circuit board so that they are basically perpendicular to the circuit board substrate; roughly determine the solder (solder paste) used for the circuit board according to the type of circuit board substrate and the type of components ) melting point temperature;

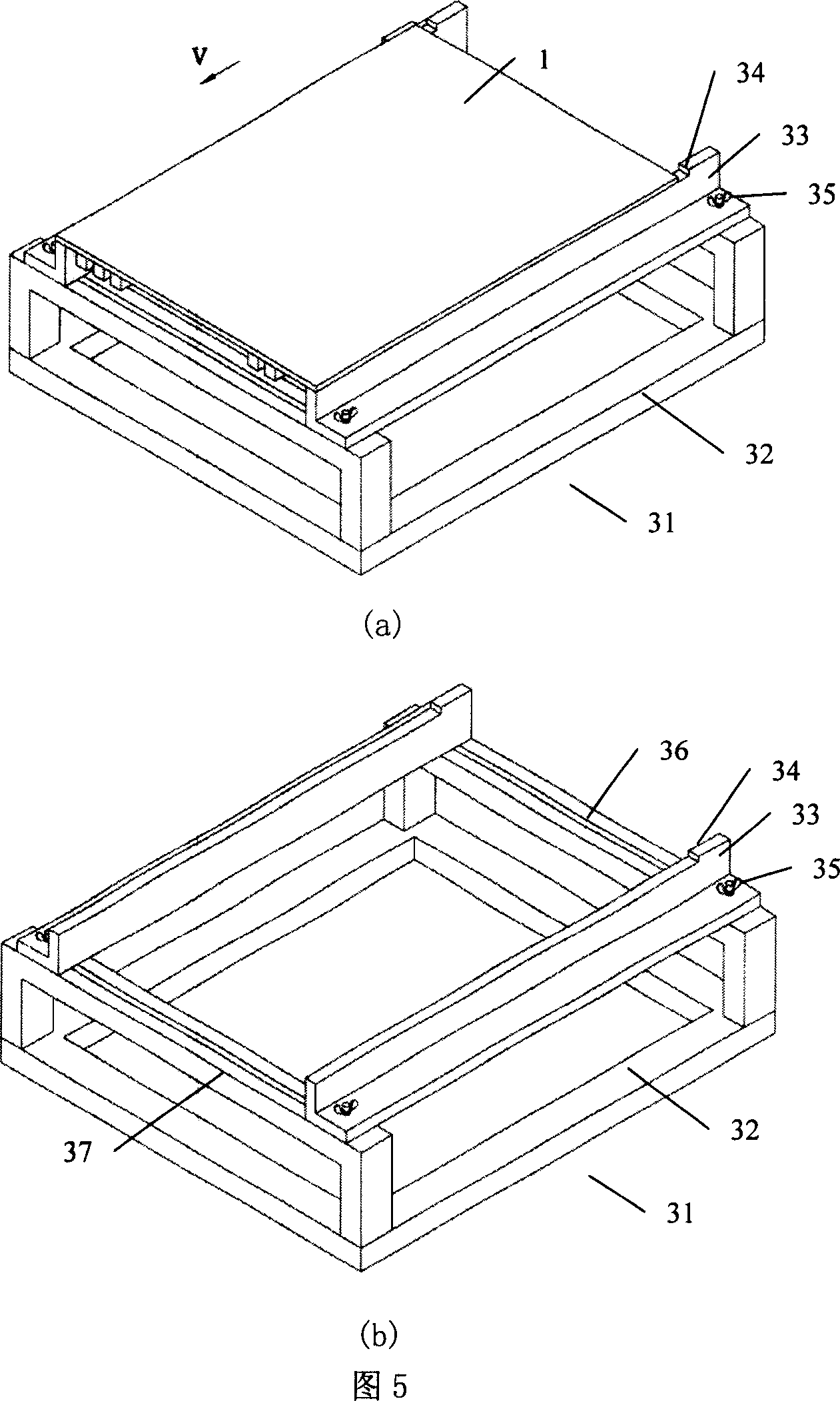

[0121] 2) Support the circuit board by means of support points: 4 or more adjustable support columns are arranged on a base of a grid structure; the base of the grid...

Embodiment 3

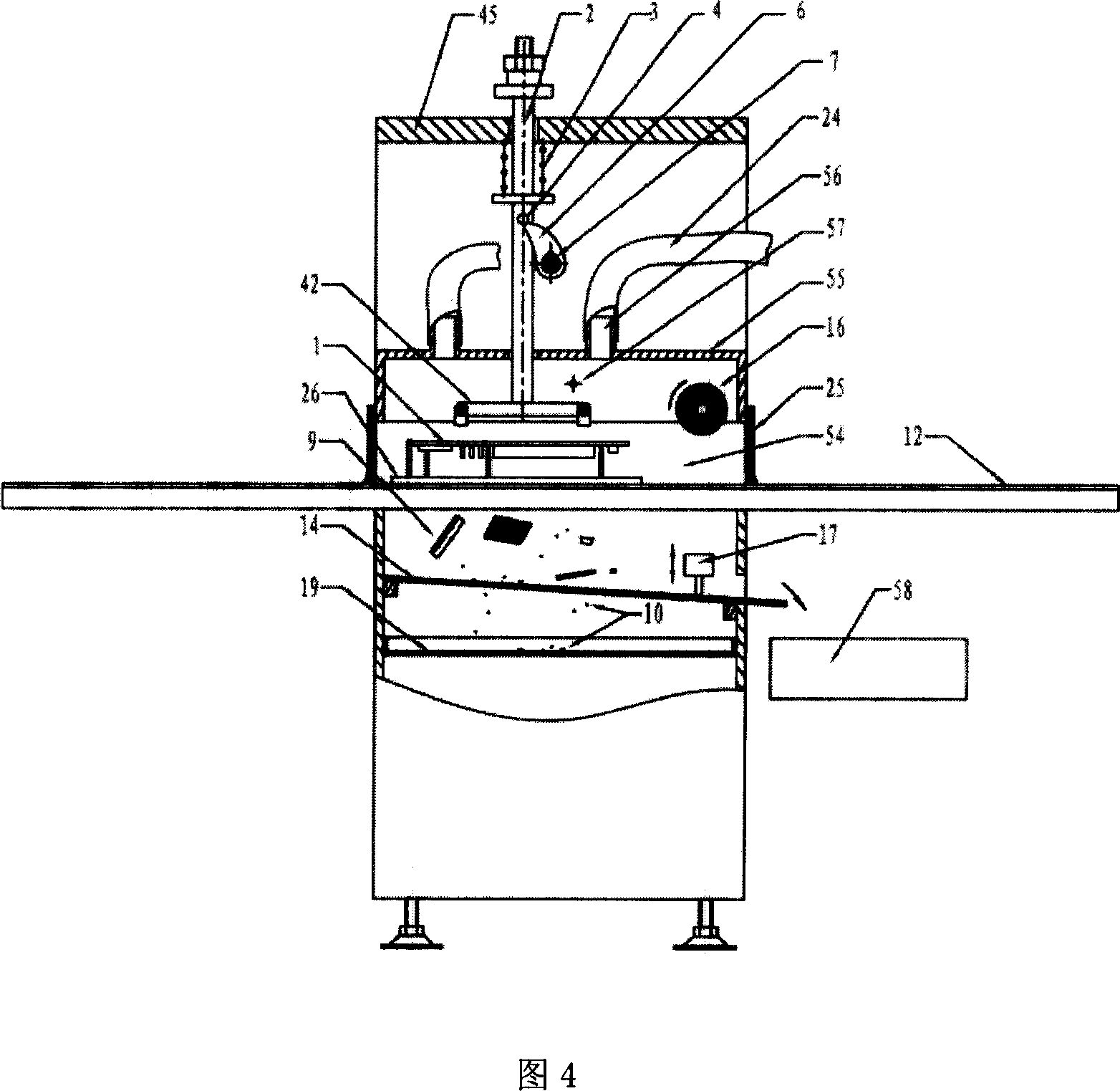

[0126] Embodiment 3 and Embodiment 4 illustrate the present invention centering on equipment.

[0127] Example 3

[0128] Fig. 3 is a schematic diagram of a circuit board dismantling device according to the present invention. The dismantling equipment uses support strips to fix the circuit board. The heating zone is divided into two zones: preheating zone and solder melting heating zone. It adopts multi-lift cam mechanism with gradually increasing impact energy, spring energy storage method and surface impact structure. Conduct contact impact on the circuit board with components, use the blower to purify the components and solder, and use the metal mesh belt moving horizontally to separate and collect the components and solder, so as to realize the insertion of components on the circuit board. Devices and SMD components are removed based on the integrity of their functions. This dismantling equipment can disassemble circuit boards with components on one side.

[0129] For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com