Integral sand core, mould for casting coupler knuckle, producing method and coupler knuckle

A knuckle and integral technology, which is applied in the field of integral sand core for knuckle casting and knuckle knuckle, can solve the problems of accelerating the contact surface, large stress and wear on the S surface of the knuckle, and achieves improved performance, small crack tendency, Good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

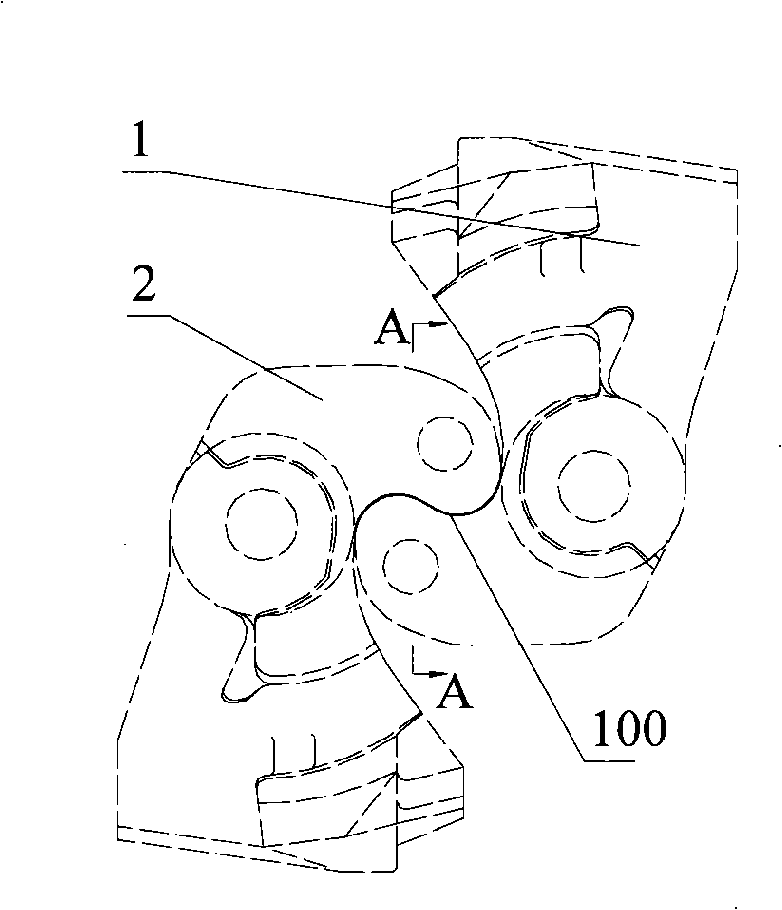

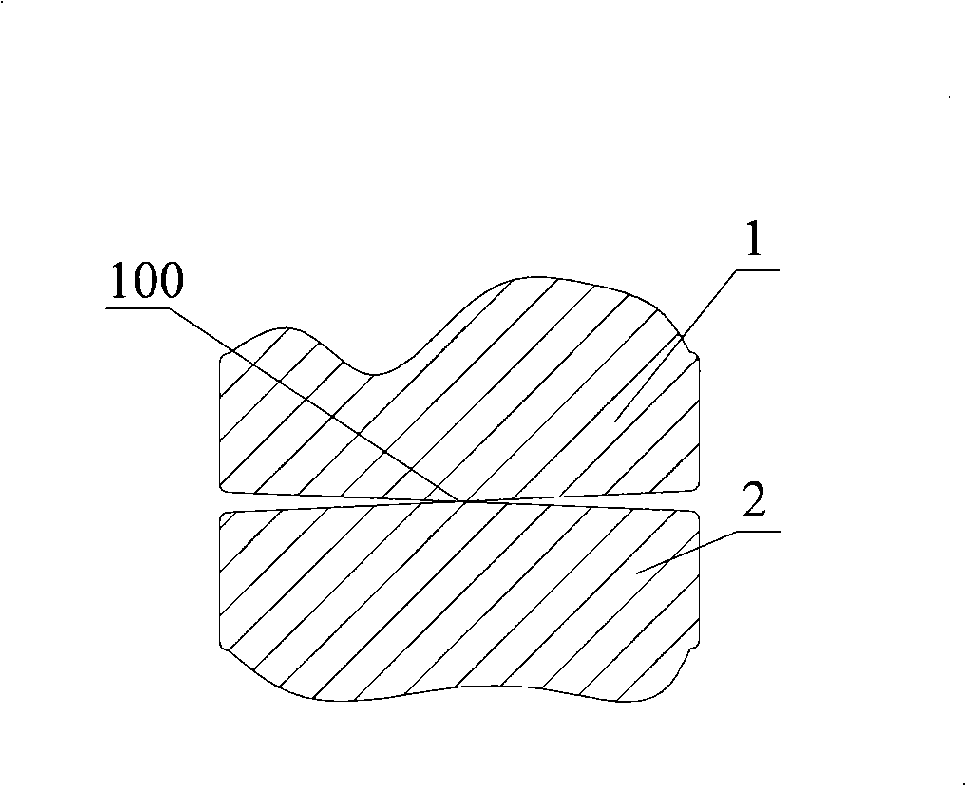

[0045] Embodiment 1 provides a tooling equipment for knuckle casting, the tooling equipment includes a sand box, a template, an integral sand core for knuckle casting, and a mold for knuckle casting. Since the sand box and template are the same as the prior art, here No more detailed description, only the integral sand core for knuckle casting and the mold for knuckle casting will be described in detail below.

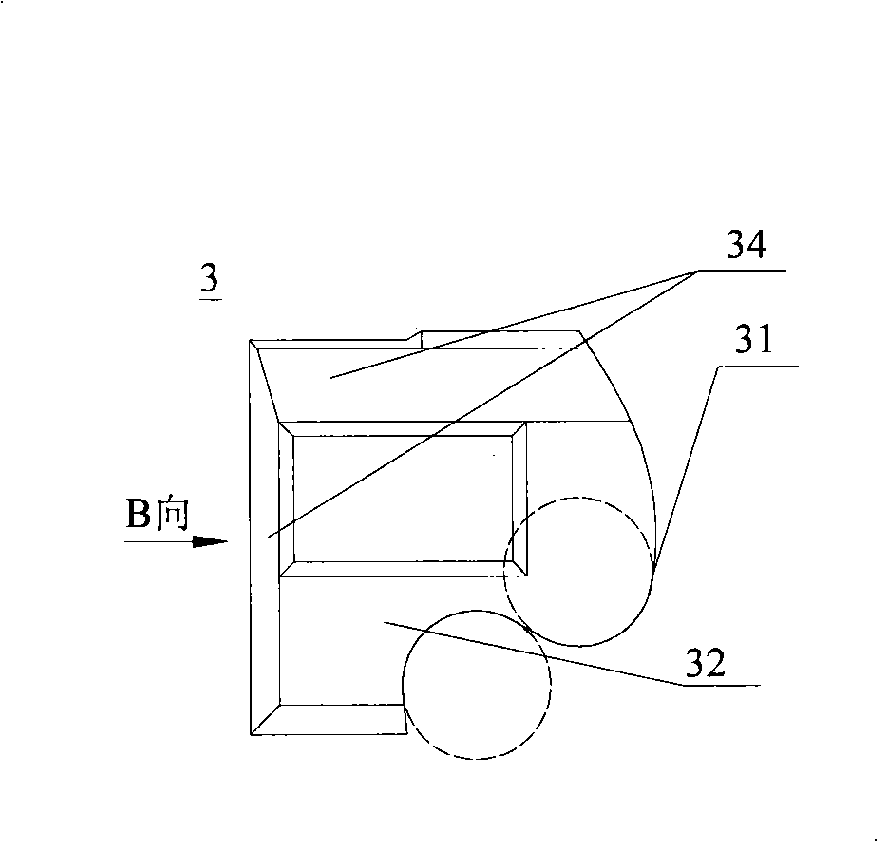

[0046] combine image 3 with Figure 4 The integrated sand core 3 for knuckle casting provided by Embodiment 1 is a polyhedron, including an S surface 31, a top surface 32, a bottom surface 33 and a side surface 34, and the side surfaces 34 intersect with the top surface 32 and the bottom surface 33 respectively, and the The S surface 31 comprises two contiguous cylindrical curved surfaces, the centerlines of the two cylindrical curved surfaces are parallel, and are respectively located on both sides of the S surface 31; the shape of the S surface 31 is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com