Adjustable self-centering inner supporting device for machining thin-wall tubular part

A technology for parts processing and supporting devices, applied in the field of adjustable self-centering inner support devices, can solve the problems of limited applicability, high centering requirements, lack of adjustability, etc. Deformation, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

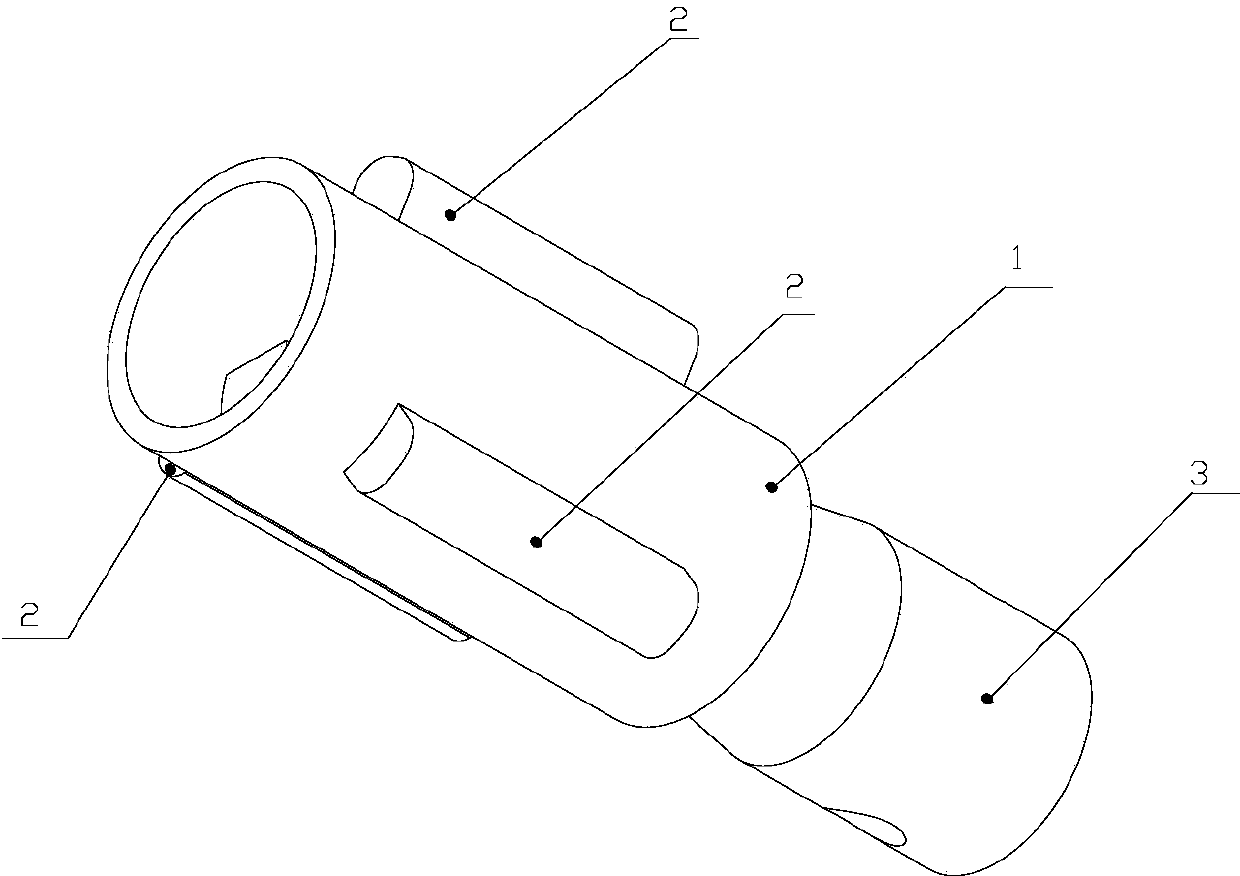

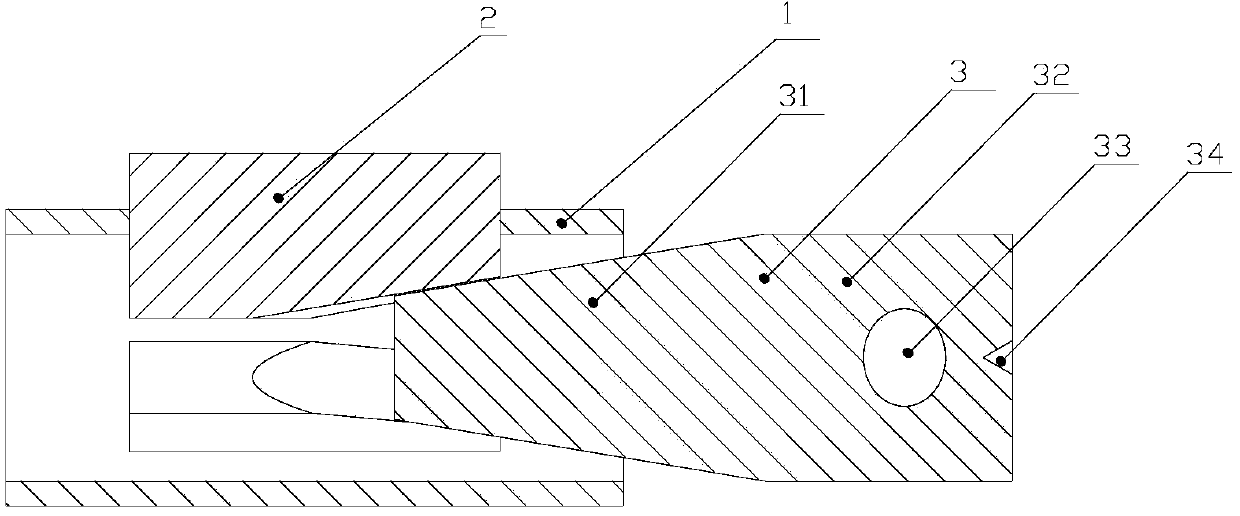

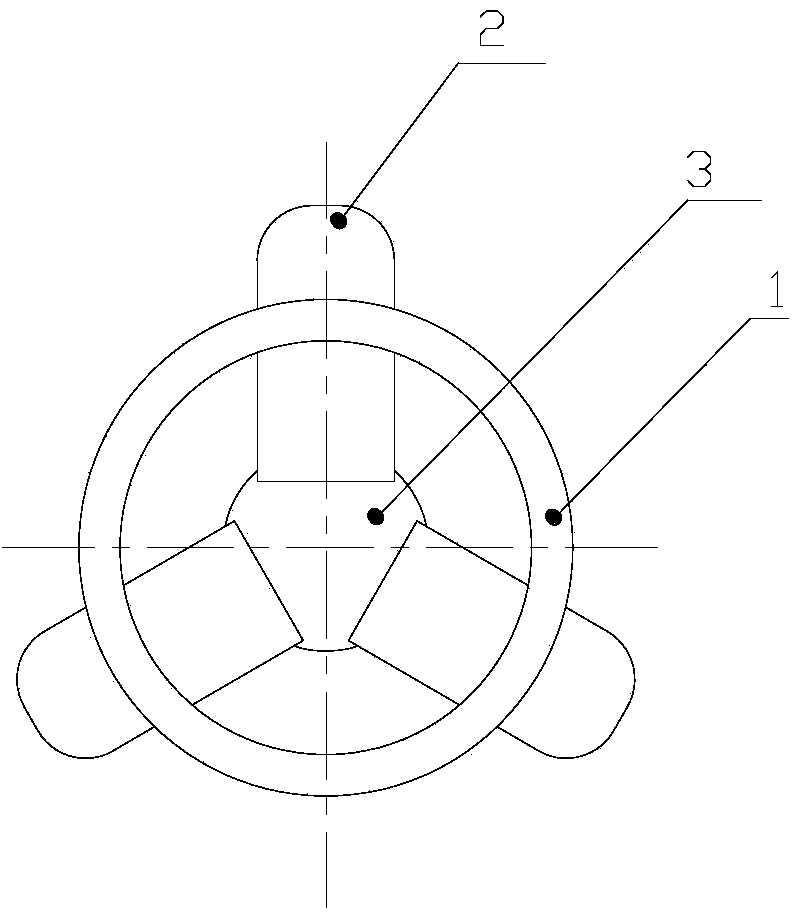

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] see Figure 1 ~ Figure 3 , an adjustable self-centering inner support device for processing thin-walled tubular parts, including an outer cylinder 1, a mandrel 3 and at least three support bars 2; the outer cylinder 1 is provided with the support bar The guide groove that the block 2 fits; the mandrel 3 is provided with a tapered shaft section 31 protruding into the outer cylinder 1 and a circular shaft section 32 exposed outside the outer cylinder 1, and the tapered shaft section 31 Tapered threads are provided, and the outer end of the circular shaft section 32 is provided with a wrenching tool connection structure. In this embodiment, the wrenching tool connection structure is a transverse through hole 33, or it can also be arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com