A forming method and forming device for a slender C-shaped cross-section sheet metal part

A forming method and technology of sheet metal parts, which are applied in the field of aviation parts processing, can solve problems such as difficult one-time forming, difficult demoulding of parts, and slender dies that are difficult to ensure rigidity, so as to improve forming efficiency and quality, and solve processing deformation problems , the effect of reducing the amount of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for forming a slender C-shaped cross-section sheet metal, characterized in that the forming method comprises the following steps:

[0037] A. U-shaped transition shape of preformed parts;

[0038] B. When using, position the part unfolded blank on the mold body with the part positioning pin, and use the mold positioning pin to position the cover plate and the mold body;

[0039] C. After the installation is completed, the U-shaped preformed shape of the part is flexibly pressed and formed by a rubber bag hydroforming machine;

[0040] D. Use manual forming dies to form the two closed corners of the parts;

[0041] E. Complete the final shape of the parts and achieve smooth pick-up.

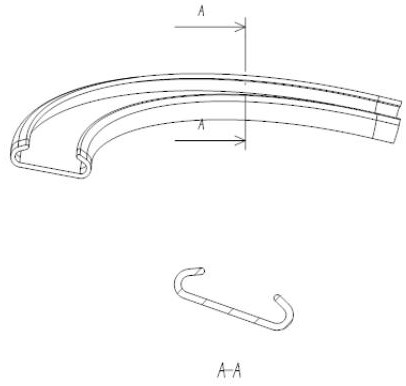

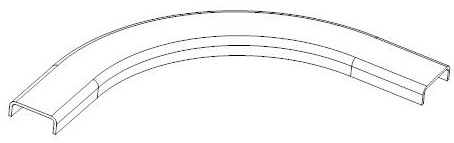

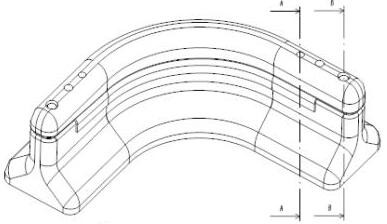

[0042] A forming device for thin and long C-shaped sheet metal parts, characterized in that it includes: a mold body 1 and a base 7, and the mold body 1 includes: a cover plate 2, a part positioning pin 3, a mold positioning pin 4 and parts The preformed shape 5, the base 7 incl...

Embodiment 2

[0044] A method for forming a slender C-shaped cross-section sheet metal, characterized in that the forming method comprises the following steps:

[0045] A. U-shaped transition shape of preformed parts;

[0046] B. When using, position the part unfolded blank on the mold body with the part positioning pin, and use the mold positioning pin to position the cover plate and the mold body;

[0047] C. After the installation is completed, the U-shaped preformed shape of the part is flexibly pressed and formed by a rubber bag hydroforming machine;

[0048] D. Use manual forming dies to form the two closed corners of the parts;

[0049] E. Complete the final shape of the parts and achieve smooth pick-up.

[0050] The detailed steps of step A are as follows: forming the intermediate transitional shape of the part with the rubber hydroforming die, making the bent edges at the closed corners at both ends of the cross section of the part vertically downward, and making the mold body U-...

Embodiment 3

[0053] A method for forming a slender C-shaped cross-section sheet metal, characterized in that the forming method comprises the following steps:

[0054] A. U-shaped transition shape of preformed parts;

[0055] B. When using, position the part unfolded blank on the mold body with the part positioning pin, and use the mold positioning pin to position the cover plate and the mold body;

[0056] C. After the installation is completed, the U-shaped preformed shape of the part is flexibly pressed and formed by a rubber bag hydroforming machine;

[0057] D. Use manual forming dies to form the two closed corners of the parts;

[0058] E. Complete the final shape of the parts and achieve smooth pick-up.

[0059] The detailed steps of step A are as follows: forming the intermediate transitional shape of the part with the rubber hydroforming die, making the bent edges at the closed corners at both ends of the cross section of the part vertically downward, and making the mold body U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com