Processing method of thin-walled vase-shaped cooling chamber

A processing method and cooling chamber technology, applied in the field of parts of the thrust chamber of liquid rocket ramjet, can solve the problems of poor cooling effect of the thrust chamber, etc., and achieve the effects of solving the problem of processing deformation, good product reliability, and easy engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A processing method for a thin-walled vase-shaped cooling chamber, comprising the following steps:

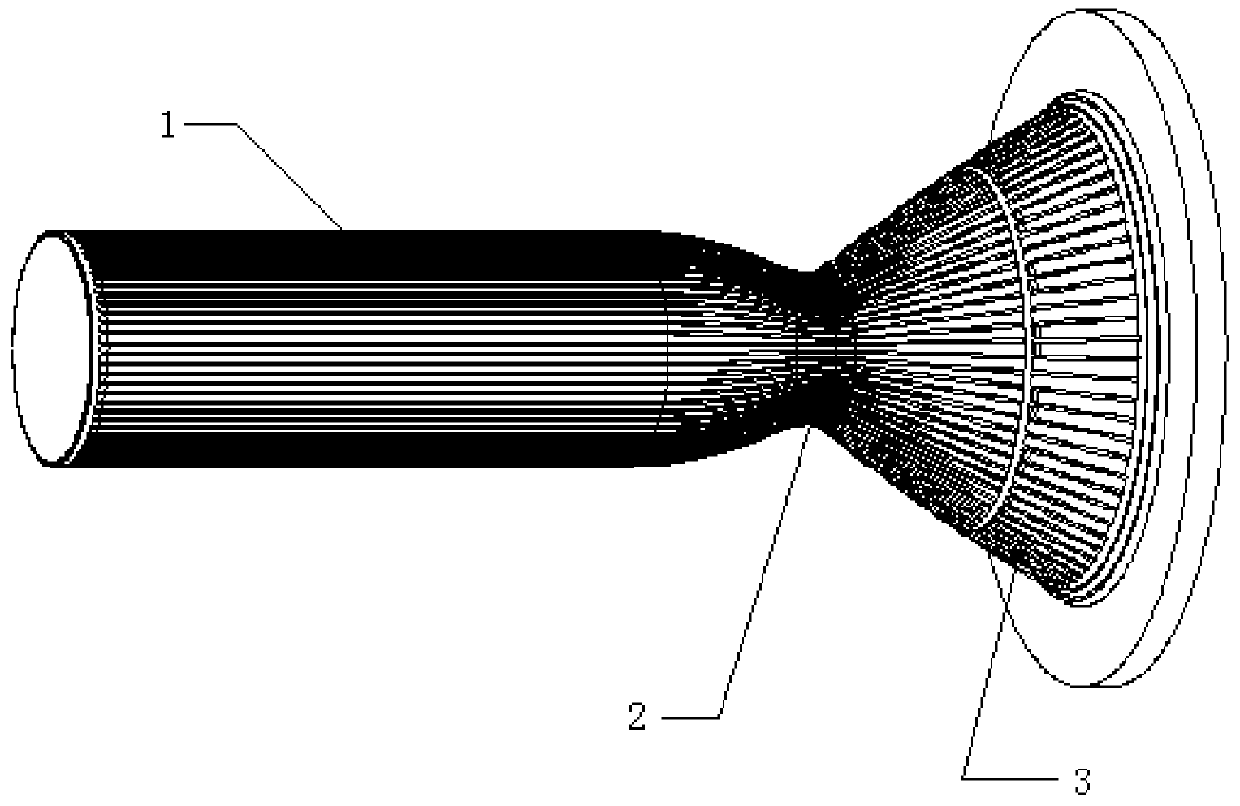

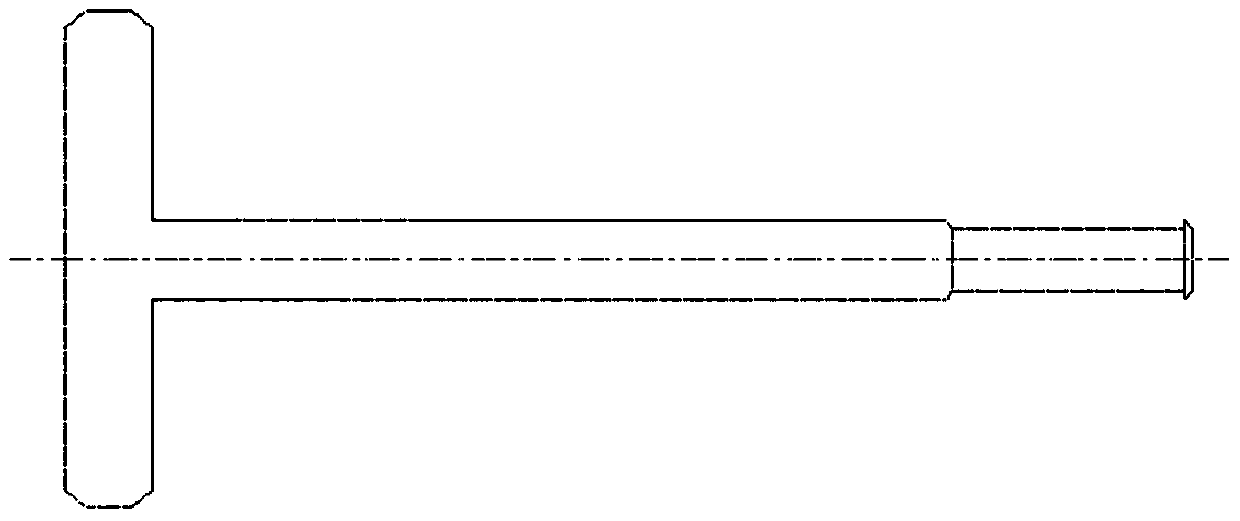

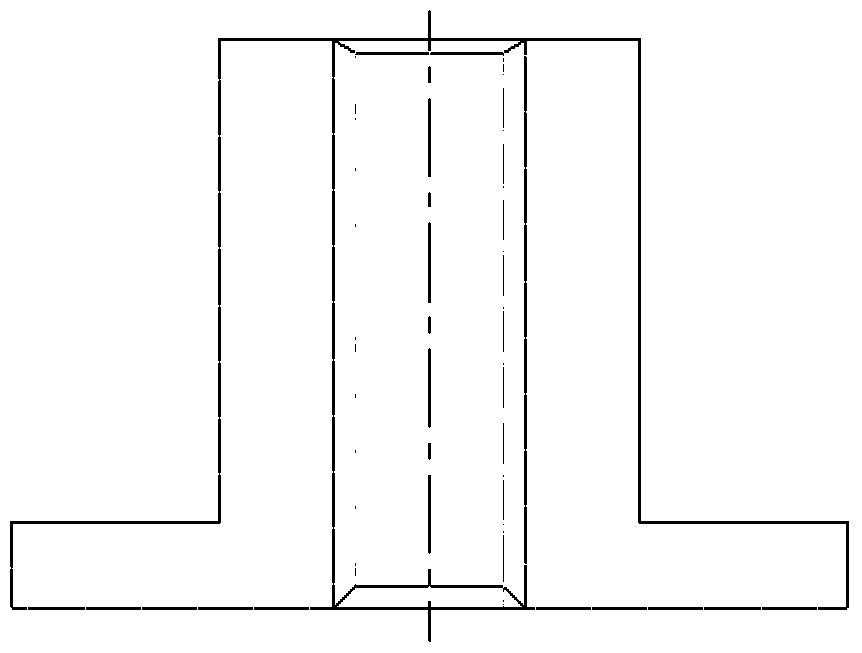

[0034] 1) Process the blank assembly according to the size of the thin-walled vase-shaped cooling chamber, the blank assembly is composed of a cylindrical forging blank 1, a throat-shaped forging blank 2 and a conical ring forging blank 3, wherein the cylindrical forging blank 1 The outer diameter of the throat-shaped forging blank 2 is a structure with a narrow middle and two large ends. The outer diameter of one end is the same as that of the cylindrical forging blank 1, and the outer diameter of the other end is the same as that of the conical ring forging blank. , the outer diameter of the conical ring forging blank 3 gradually increases from one end to the other end and a circular ring is arranged on the extension of the large diameter end of the conical ring forging blank 3;

[0035] The outer diameter φ of one end of the cylindrical forging blank 1 is 158 mm, the ...

Embodiment 2

[0045] A processing method for a thin-walled vase-shaped cooling chamber, comprising the following steps:

[0046] 1) Process the blank assembly according to the size of the thin-walled vase-shaped cooling chamber, the blank assembly is composed of a cylindrical forging blank 1, a throat-shaped forging blank 2 and a conical ring forging blank 3, wherein the cylindrical forging blank 1 The outer diameter of the throat-shaped forging blank 2 is a structure with a narrow middle and two large ends. The outer diameter of one end is the same as that of the cylindrical forging blank 1, and the outer diameter of the other end is the same as that of the conical ring forging blank. , the outer diameter of the conical ring forging blank 3 gradually increases from one end to the other end and a circular ring is arranged on the extension of the large diameter end of the conical ring forging blank 3;

[0047] The outer diameter φ of one end of the cylindrical forging blank 1 is 164mm, the o...

Embodiment 3

[0057] A processing method for a thin-walled vase-shaped cooling chamber, comprising the following steps:

[0058] 1) Process the blank assembly according to the size of the thin-walled vase-shaped cooling chamber, the blank assembly is composed of a cylindrical forging blank 1, a throat-shaped forging blank 2 and a conical ring forging blank 3, wherein the cylindrical forging blank 1 The outer diameter of the throat-shaped forging blank 2 is a structure with a narrow middle and two large ends. The outer diameter of one end is the same as that of the cylindrical forging blank 1, and the outer diameter of the other end is the same as that of the conical ring forging blank. , the outer diameter of the conical ring forging blank 3 gradually increases from one end to the other end and a circular ring is arranged on the extension of the large diameter end of the conical ring forging blank 3;

[0059] The outer diameter φ of one end of the cylindrical forging blank 1 is 168mm, the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com