Grinding clamp and clamping method suitable for thin-wall long spacer bush

A spacer, thin-walled technology, applied in the direction of grinding workpiece supports, can solve the problems of easy deformation, inability to guarantee product quality, affecting the dimensional accuracy and shape accuracy of parts, to reduce deformation, improve product quality and processing efficiency. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

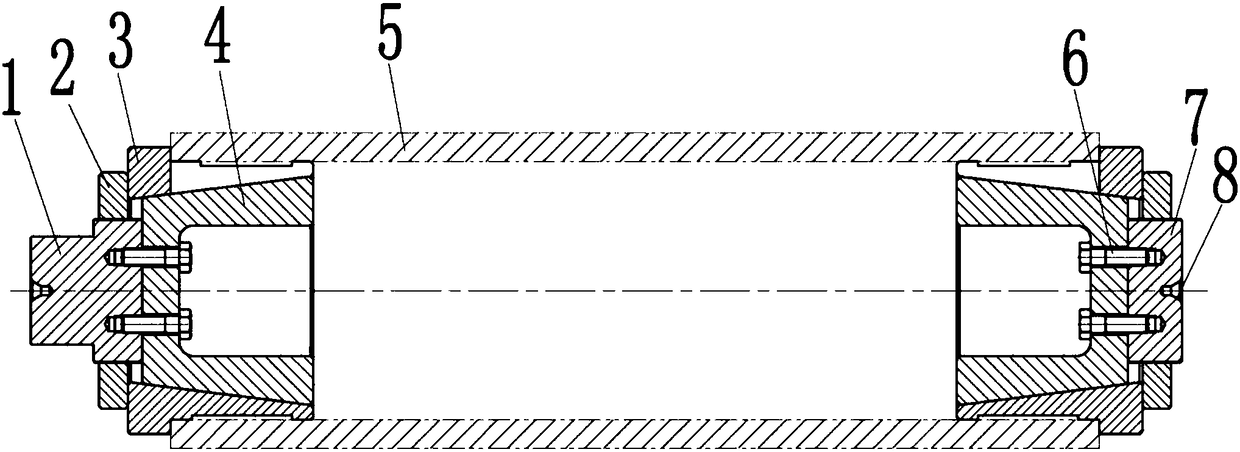

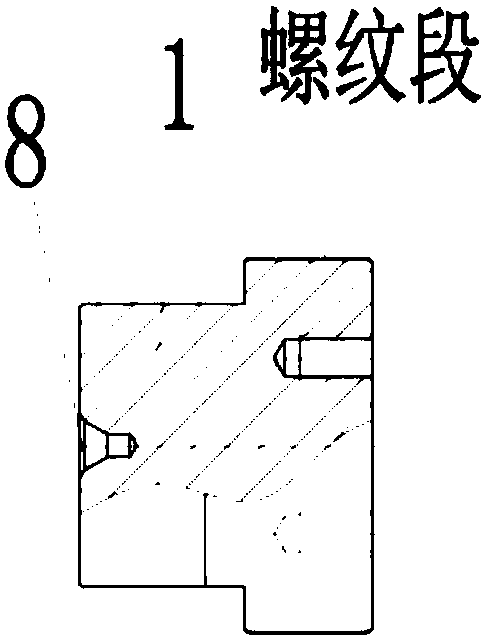

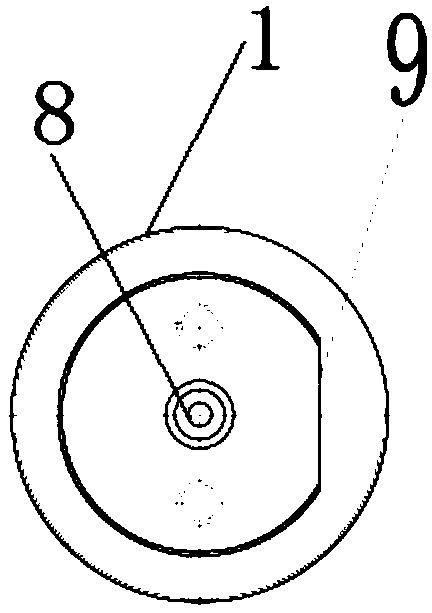

[0031] The invention is a kind of grinding fixture suitable for thin-walled long spacers, the structure is as follows figure 1 As shown, it comprises a dial base 1 and a top disc base 7 which are arranged oppositely on the left and right sides, and the dial base 1 and the top disc base 7 are all threaded with an adjusting round nut 2, the right end surface of the dial base 1 and The left end face of the top plate seat 7 is detachably connected with a transition cone cap 4 whose outer surface is an outer cone surface. The upper surface is provided with matching elastic cone sleeves 3, and one end corresponding to the two elastic cone sleeves 3 is sleeved with a thin-walled long spacer 5, and the other end of the elastic cone sleeve 3 is located between the adjusting round nut 2 and the thin-walled length between 5 spacers.

[0032] The right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com