Silicon-oxygen-carbon ceramic products and preparing method thereof

A technology of silicon carbon ceramics and products, which is applied in the field of silicon carbon ceramic products and its preparation, silicon carbon ceramic parts, and can solve problems affecting the formation of ceramic bodies, cracking of precursors, differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

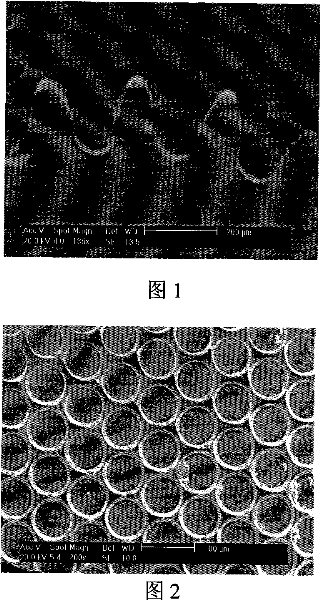

[0030] Use 10g polymethylhydrogensiloxane (viscosity: 15-50mPa.s (20°C)) and 10g tetramethyltetravinyl cyclotetrasiloxane (viscosity: 15-60mPa.s (20°C)) as silicon Oxygen carbon precursor, mix the two, add a platinum complex catalyst with a mass fraction of 1%, and prepare a liquid phase precursor; use vinyl-terminated polydimethylsiloxane and polymethylhydrogensiloxane as The mold material precursor is made of ferrous metal micro-gear as the parent part. The combination of the two, the mold material precursor is cured and demoulded, and the polysiloxane micro-gear negative mold is prepared. Through mold transfer, the micro-gear pattern is transferred to the polysiloxane. Heating the siloxane ceramic precursor to 80°C for cross-linking reaction for 6 hours to obtain a cured siloxane ceramic precursor, put the cross-linked and cured siloxane ceramic precursor in a tube furnace, Pyrolysis at 900°C for 2 hours in the airflow to obtain ceramic micro-gears with a ceramic yield of 8...

Embodiment 2

[0032] Using the copper mesh micro-grid as the master piece, the cured polysiloxane mold material printed with the negative mold of the micro-grid is prepared, and the cured siloxane precursor is obtained through mold transfer and cross-linking reaction. Other experimental steps and conditions are the same as the implementation Example 1, the ceramic microhole array of the microgrid was obtained, the hole size was 70 μm, the small hole was 1 μm, and the precision of the microstructure of the master was copied to the sub-micron level. The scanning electron micrograph of the obtained microwell array is shown in Fig. 2 .

Embodiment 3

[0034] Using 10g of polymethylhydrogensiloxane and 10g of tetramethyltetravinylcyclotetrasiloxane as silicon carbon precursors, using solid polyethylene micro-gear as mold material, other conditions are the same as in Example 1, after heating and curing Demolding leads to cracking of the molded body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com