Electric fluid dynamic spray printing equipment for flexible dielectric substrate and control method

A flexible medium, electro-fluid technology, applied in power transmission devices, printing, printing devices, etc., can solve the problems of flexible electronic characterization and performance impact, flexible electronic circuit breaker, affecting the service life and reliability of flexible electronics, etc., to improve the pattern Printing quality, improved performance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

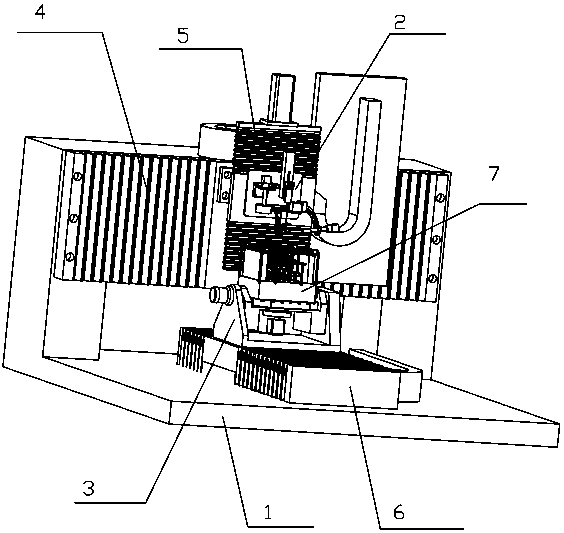

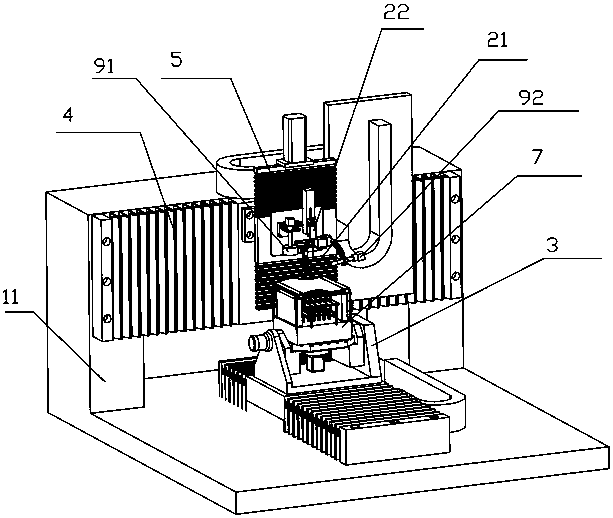

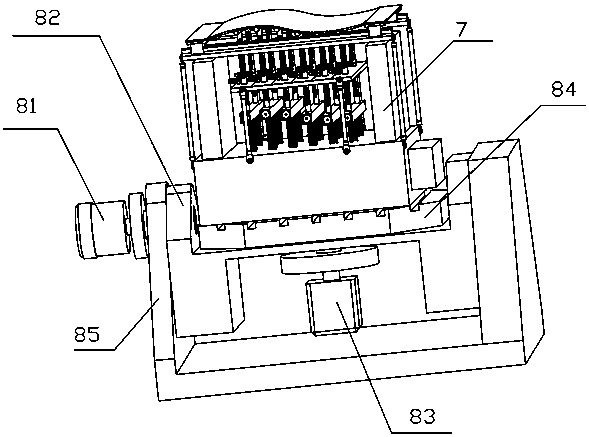

[0035] Depend on figure 1 to combine Figure 2-8As shown, an electrohydrodynamic jet printing equipment for a flexible dielectric substrate, including a support 1, a jet printing module 2, a jet printing platform 3, a high-voltage power supply module and a curing module, and the jet printing module 2 slides through the X-axis The mechanism 4 and the Z-axis sliding mechanism 5 are arranged on the support 1. The printing module 2 includes a flow pump 22 and a nozzle 21. The flow pump 22 drives the printing solution to fill the nozzle through pressure. The nozzle 21. Under the action of the electric field force generated by the high-voltage power supply module, the solution is sprayed onto the flexible medium substrate to be printed to form a printing pattern, and the curing module sinters and solidifies the printing pattern on the flexible medium substrate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com