Method for manufacturing cylinder with circumferential inner reinforcing rib

A technology of internal reinforcing ribs and manufacturing methods, which can be applied to other household appliances, household appliances, applications, etc., can solve the problems that the thickness of forgings cannot be saved, the product accuracy is difficult to guarantee, and the fatigue impact resistance is weak, etc., to achieve fast processing time, The effect of high production efficiency and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

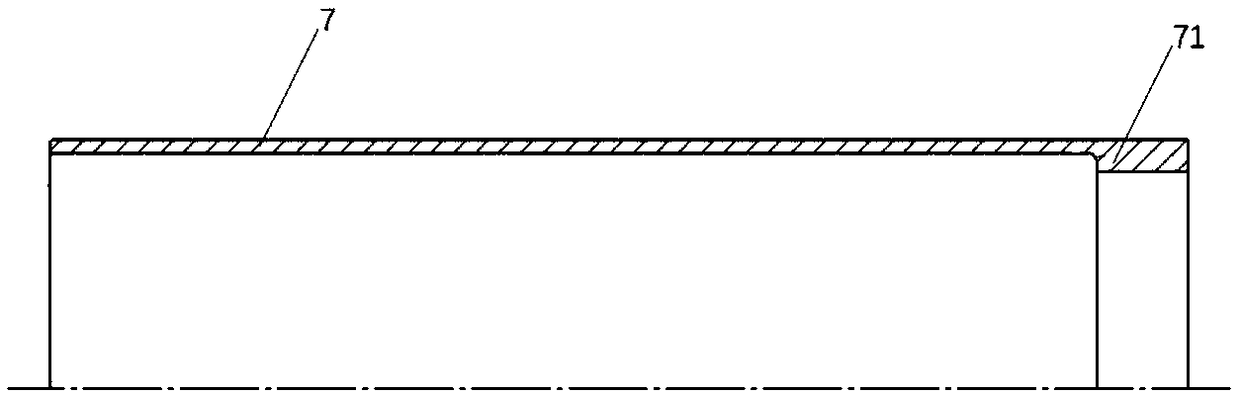

[0026] This embodiment provides a image 3 The manufacturing method of the cylindrical body 7 with rings inwardly reinforcing ribs shown includes the following steps:

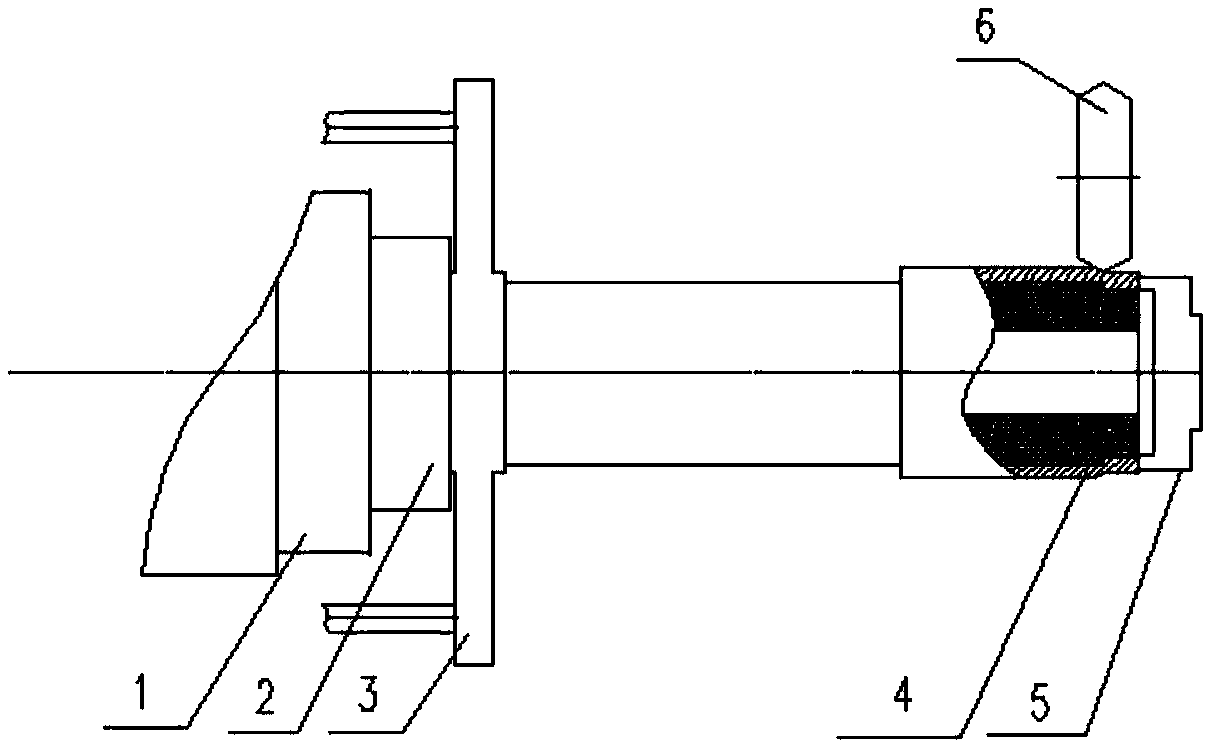

[0027] Step 1. Sleeve and fix the disc-shaped limiter 3 on the mandrel 2 connected to the main shaft 1, the limiter 3 is connected to the servo cylinder, and the end of the mandrel 2 is set to be strengthened on the cylinder The ring-shaped groove with the matching shape of the inner rib preheats the mandrel 2 and keeps the temperature of the mandrel 2 at 500-550°C;

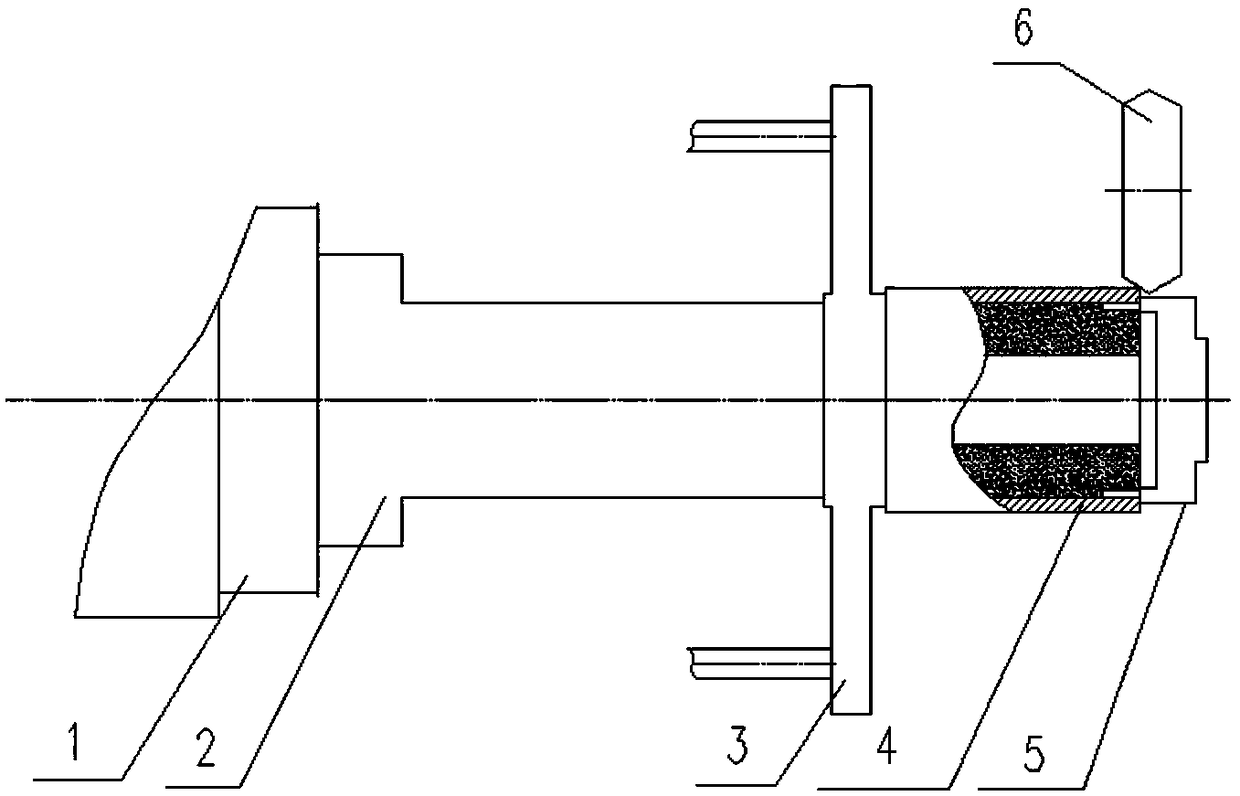

[0028] Step 2, such as figure 1 As shown, the blank 4 is partly set on the end of the mandrel 2, and the tail top 5 is set at the rear end of the blank 4. The tail top 5 is connected to the oil cylinder and can be driven by the oil cylinder to approach or move away from the rear end of the blank 4. On the side of the blank 4 The rotary wheel 6 is installed, and the rotary wheel 6 is installed on the rotary wheel shaft of the equipment and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com