Ultralow-temperature flexible forming device for complex thin-walled aluminum-lithium alloy structural part

A technology of thin-walled structural parts and aluminum-lithium alloys, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult-to-form shape components, prone to micro-cracks, and poor fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

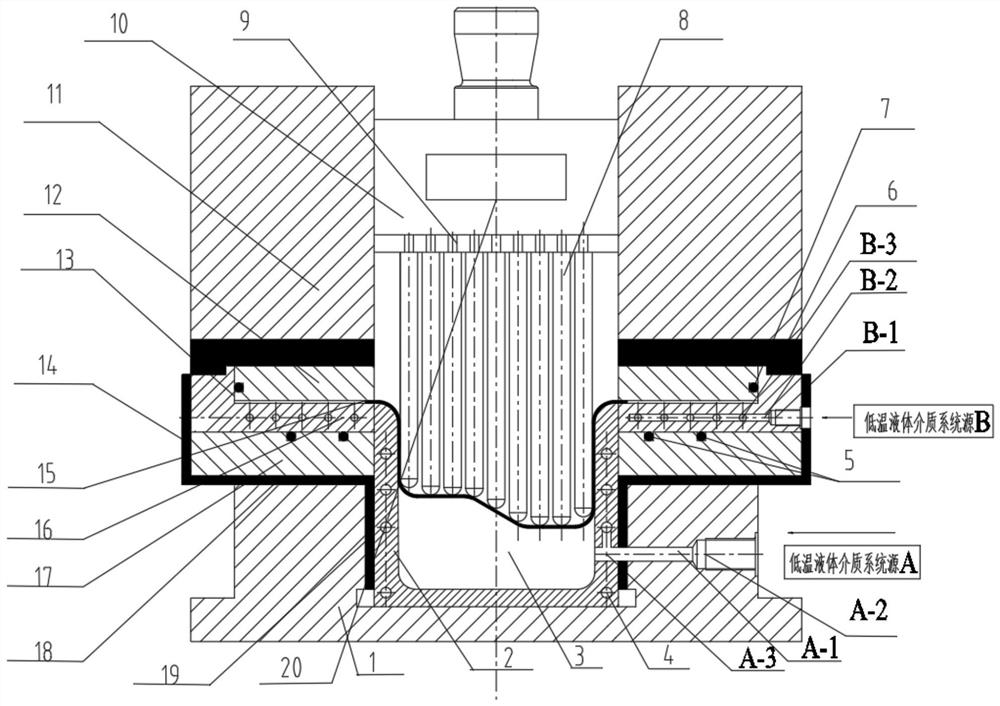

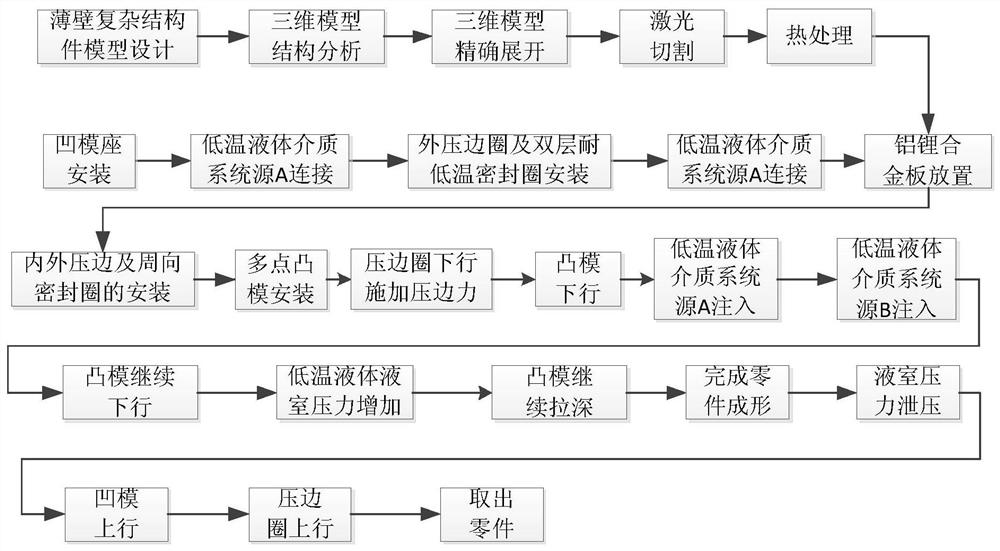

[0084] Such as Figure 1-Figure 7 As shown, the forming device includes a die base 1, a die cover 2, a double-layer low-temperature resistant sealing ring 5, a first cold insulation layer 6, an ultra-low temperature circumferential sealing ring 7, a multi-point punch head 8, and a punch connection Column 9, punch body 10, first blankholder ring 11, second blankholder inner ring 12, second cold insulation layer 14, aluminum-lithium alloy plate 15, low-temperature forming die pad A16, die seat pad B17, the third cold insulation layer 18, the fourth cold insulation layer 19;

[0085] The die set 2 is a hollow cylinder with an open bottom and the inner cavity of the die set 2, the cavity surrounded by the multi-point punch head 8 of different shapes and the aluminum-lithium alloy plate 15 together form a high-pressure and low-temperature chamber of different shapes. Liquid-filled chamber 3;

[0086] Between the low-temperature die forming cushion block A16 and the die seat cushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com