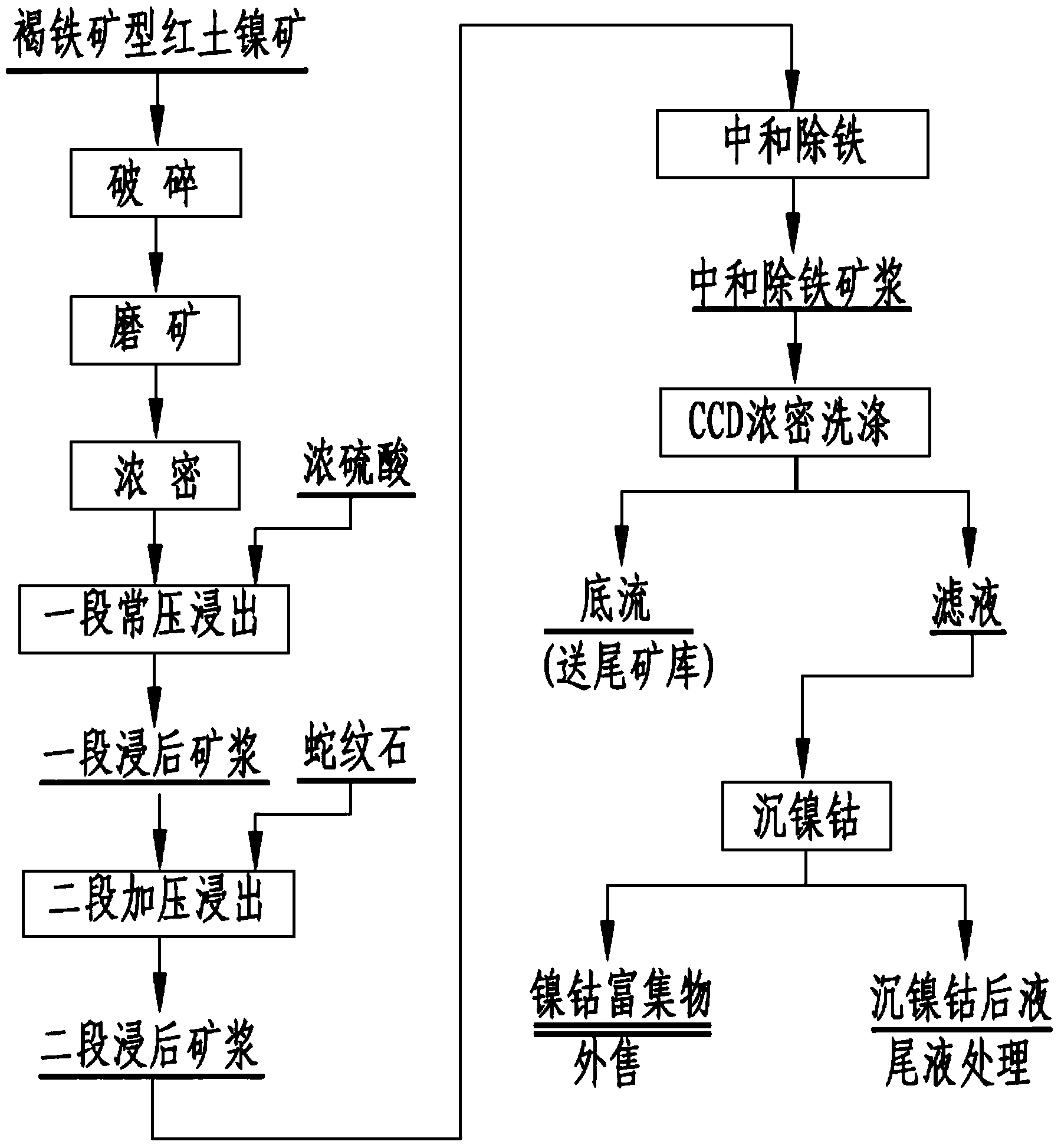

Laterite-nickel ore combination leaching process

A technology of laterite nickel ore and joint leaching, applied in the direction of improving process efficiency, can solve the problems of large project investment, high production and operation cost, and high requirements for high-pressure acid leaching process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

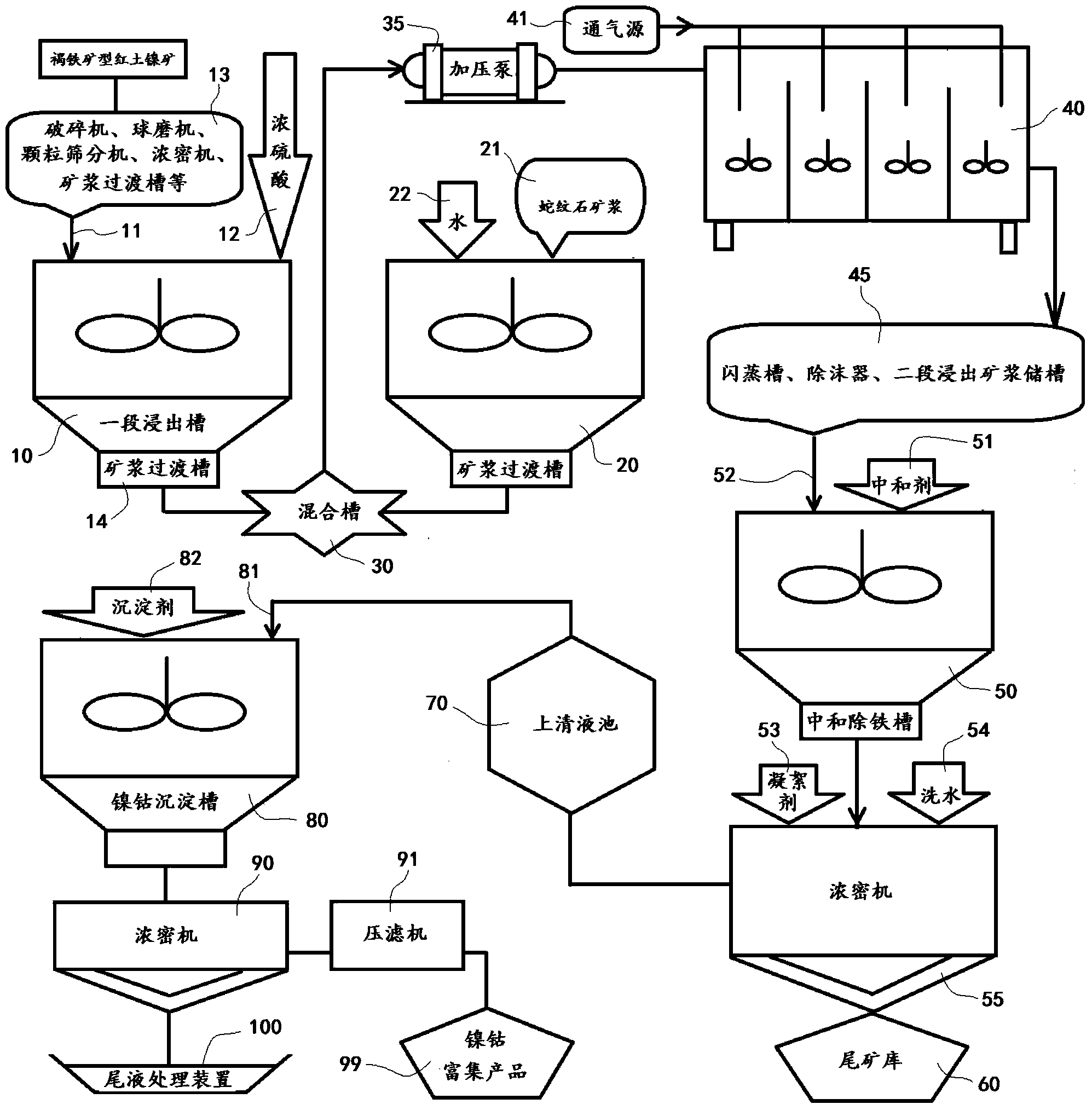

Embodiment 1

[0062] Take 200g (dry basis) limonite-type lateritic nickel ore (Ni1.17%, Co0.10%, Fe43.05%, MgO1.43%), add water to adjust the slurry concentration to 33%, and use 98%H 2 SO 4 The solution is self-heating and stirring leaching under normal pressure. The leaching temperature is 95°C. After 6 hours of leaching, the leaching rates of nickel and cobalt reach 98.11% and 96.48%, respectively, and the total acid consumption is 224.48g, which is 1.1t acid / t ore.

[0063] Take 200g (dry basis) serpentine-type laterite nickel ore (Ni1.54%, Co0.02%, Fe5.53%, MgO32.0%), adjust the slurry concentration to 33%, and mix it with the slurry after normal pressure leaching After that, it is sent to the pressure kettle for two-stage pressure leaching. The leaching temperature is 150°C for 2 hours, the leaching pressure is 0.45MPa, the total leaching rates of nickel and cobalt reach 93.61% and 91.39% respectively, and the total acid consumption is 550kg / t ore . The Fe content of the solution af...

Embodiment 2

[0072] Take 800g of mixed laterite nickel ore (Ni1.52%, Fe16.32%, MgO23.49%, Si16.09%), and pass through 1mm sieve to obtain -1mm under-sieve ore (Ni1.54%, Fe18.68% , MgO21.05%, Si15.19%) 512g, +1mm sieve ore (Ni1.47%, Fe11.95%, MgO28.03%, Si17.76%) 288g, add water to adjust the slurry concentration to 35%, using 98%H2 SO 4 The solution is leached with self-heating and stirring under normal pressure. The leaching temperature is 100°C. After leaching for 5 hours, the nickel leaching rate reaches 98.45%, and the total acid consumption is 512g, which is 1t acid / t ore.

[0073] Take 288g+1mm sieve ore and grind it, add water to adjust the slurry concentration to 35%, mix it with the slurry after one-stage -1mm under-sieve ore leaching under normal pressure, then put it into the autoclave for two-stage pressure leaching, at a leaching temperature of 160°C Under leaching for 1.5h, the leaching pressure is 0.48MPa, the total nickel leaching rate reaches 94.05%, and the total acid co...

Embodiment 3

[0082] 420.5kg (dry basis) of limonite-type lateritic nickel ore (Ni1.18%, Co0.10%, Fe41.15%, MgO2.45%) was crushed and ground with 98%H 2 SO 4 The solution was leached with self-heating and stirring under normal pressure. After 4 hours of leaching, the leaching rates of nickel and cobalt reached 97.55% and 95.37%, respectively, and the total acid consumption was 462.55kg, equivalent to 1.1t acid / t ore.

[0083] Take 420.5kg (dry basis) of serpentine-type lateritic nickel ore (Ni1.55%, Co0.07%, Fe5.43%, MgO28.95%), adjust the slurry concentration to 33%-35%, and normal pressure After leaching, the ore slurry is mixed and sent to a pressure kettle for two-stage pressure leaching. Stirring and leaching under normal pressure for 2 hours at a leaching temperature of 140-160 ° C, the leaching rates of nickel and cobalt reach 94.14% and 92.58% respectively, and the obtained pressure leaching The pulp is 1298.33kg.

[0084] After pressure leaching, the slurry is added to limestone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com