Method for predicting shrinkage cavity defect of TC4 titanium alloy casting through BP neural network

A BP neural network, titanium alloy technology, applied in the direction of neural learning methods, biological neural network models, special data processing applications, etc., can solve the problems of casting mold filling and solidification, different results and precision, and reduced accuracy without comprehensive consideration , to achieve extensive social and economic benefits, save production and experiment costs, and improve the utilization rate of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

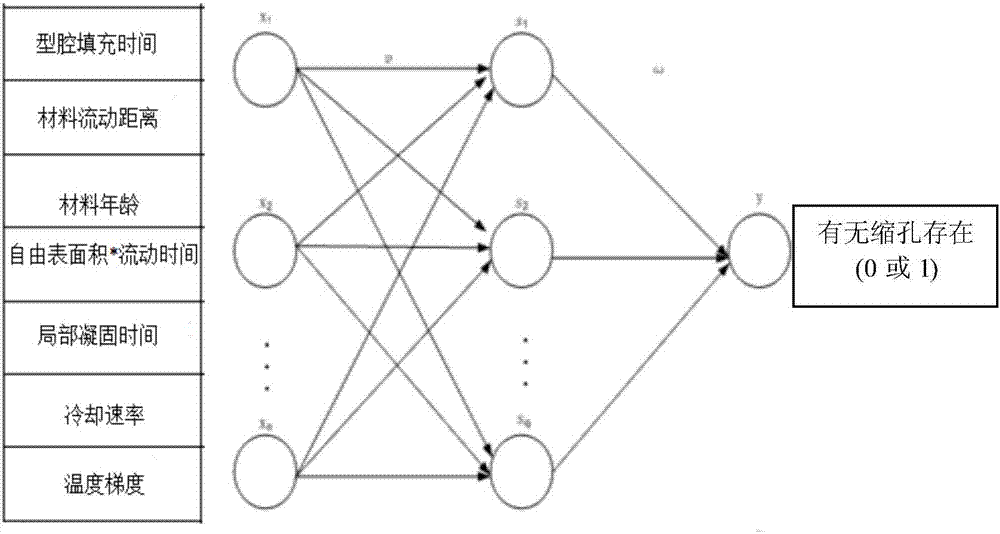

[0051] The structure of BP neural network is as follows figure 1 shown.

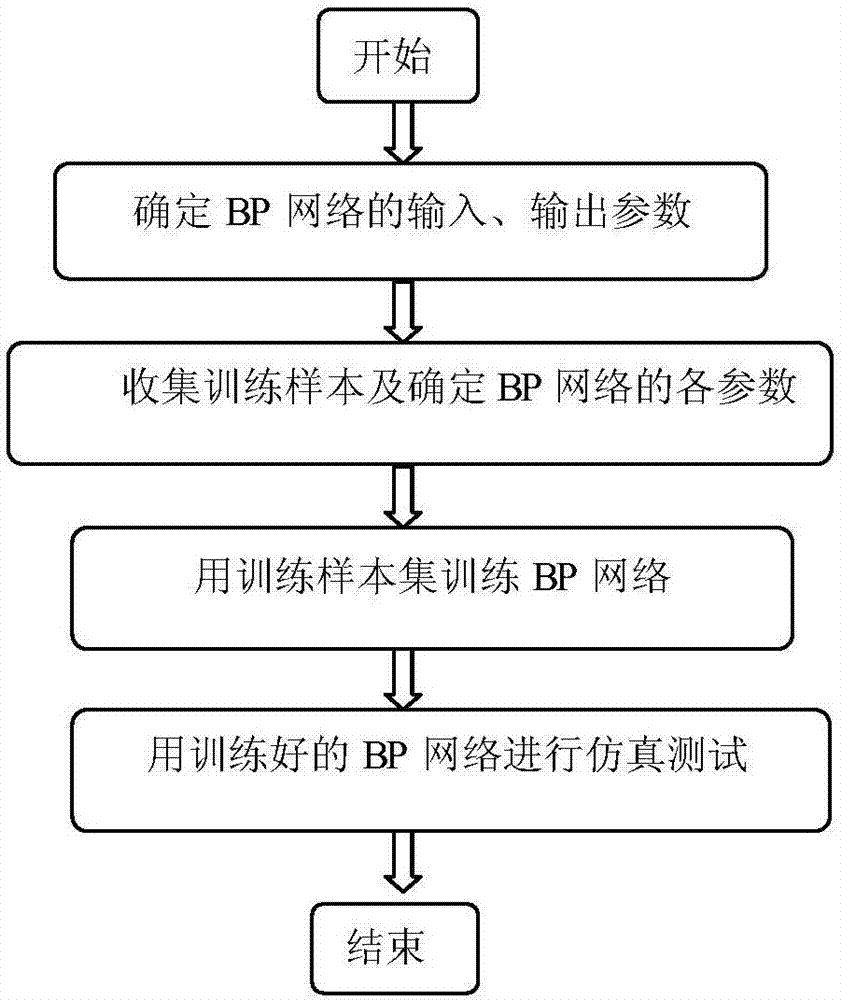

[0052] Application of BP neural network method to predict shrinkage cavity defects in TC4 titanium alloy castings includes the following steps (such as figure 2 shown):

[0053] (1) According to the causes of shrinkage cavity formation and the characteristics of titanium alloy investment casting, seven parameters are selected: cavity filling time, material flow distance, material age, free surface area*flow time, local solidification time, cooling rate, temperature gradient As the input of the BP neural network, whether there is a shrinkage cavity in the corresponding position (there is a shrinkage cavity is recorded as 1, otherwise it is recorded as 0) as the output of the BP neural network;

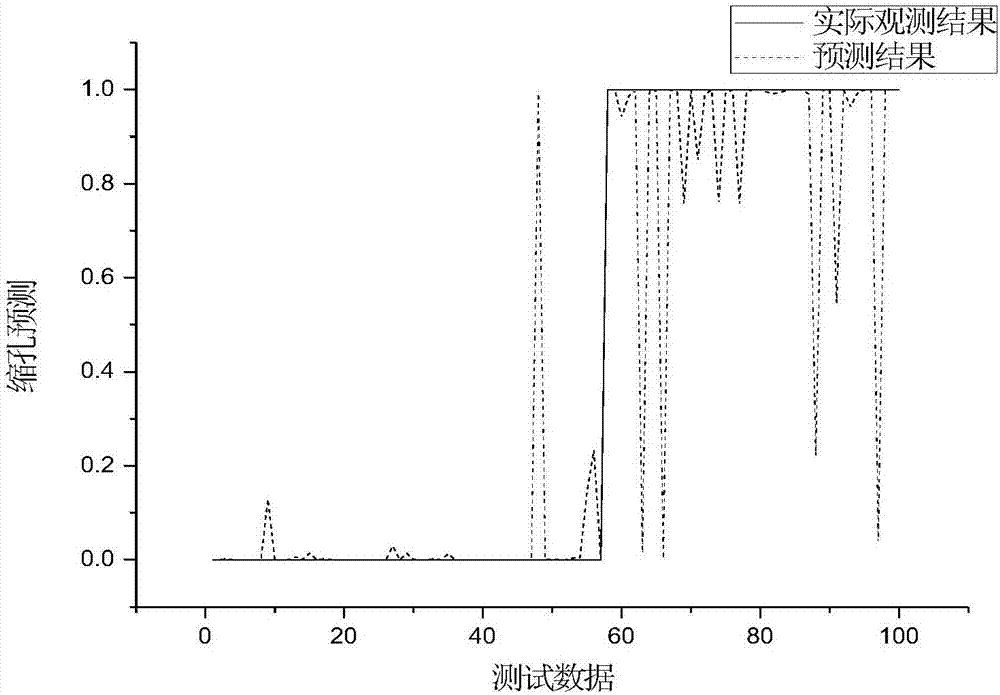

[0054] (2) Use ProCAST software to simulate the investment casting process of TC4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com