Treatment method of sodium-roasted-leached-acid ammonium salt vanadium precipitation waste water

A technology of acidic ammonium salt vanadium precipitation and sodium roasting, which is applied in the direction of heating water/sewage treatment, etc., and can solve the problem of high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

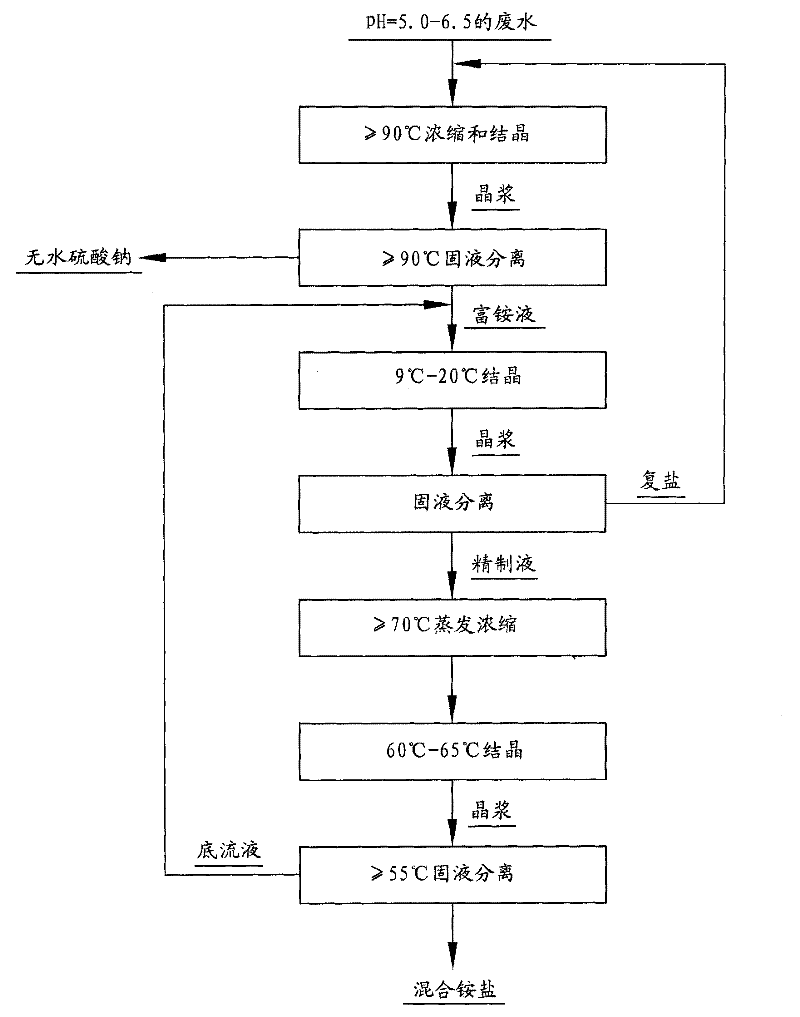

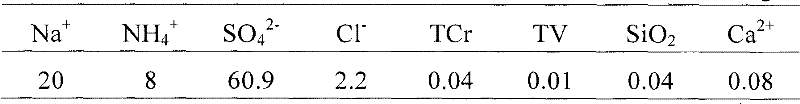

[0037] Get the sodium salt method waste water 1000L (pH is 8~9.5) after removing the vanadium chromium through filtering, be that its pH=5.6 is adjusted with the industrial sulfuric acid of 50% concentration, with the processing speed of 10L / h on the test device according to the present invention processing method.

[0038] The main parameters are:

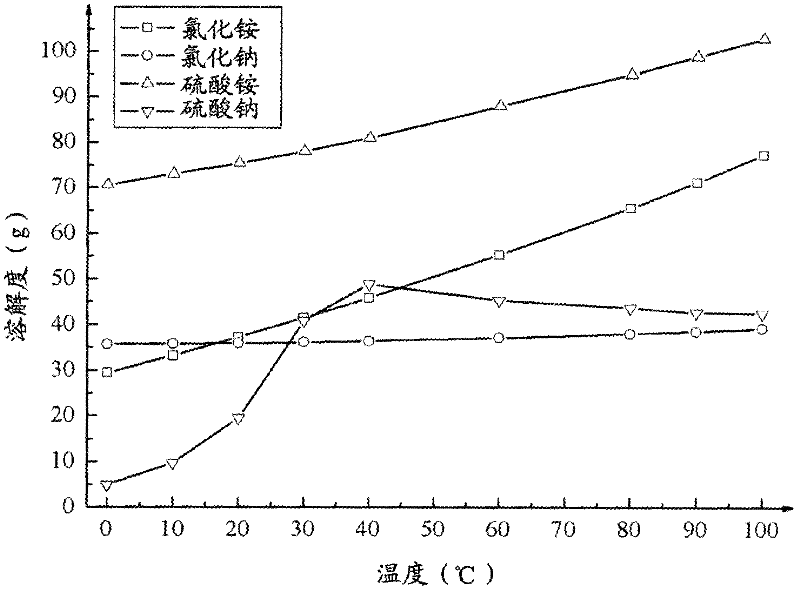

[0039] Normal pressure, sodium sulfate crystal evaporation and crystallization temperature of 103-107°C, stirring speed of 380rpm, concentration ratio of 9.2:1, crystallization time of 1 hour, heat preservation and suction filtration temperature of 92°C, to obtain anhydrous sodium sulfate and ammonium-enriched liquid.

[0040] Cool the ammonium-enriched solution to 13°C, and after 4.5 hours of natural crystallization at constant temperature, perform suction filtration to obtain double salt residue and refined solution. The double salt slag is directly redissolved in the initial wastewater storage device.

[0041] The refined sol...

example 2

[0053] Get 2000L of sodium salt process acidic wastewater and filter it, adjust its pH=6.2 with a 30% caustic soda aqueous solution, and treat it according to the treatment method of the present invention with a treatment speed of 15L / h on the test device.

[0054] The main parameters are:

[0055] Negative pressure, sodium sulfate crystal evaporation crystallization temperature 95 ~ 100 ℃, stirring speed 380rpm, concentration ratio 9.2:1. The crystallization time is 1 hour, and the heat preservation and suction filtration temperature is 93° C. to obtain anhydrous sodium sulfate and ammonium-enriched liquid.

[0056] Cool the ammonium-enriched solution to 11°C, and after natural crystallization at constant temperature for 4.5 hours, perform suction filtration to obtain double salt residue and refined solution. The double salt slag is directly redissolved in the initial wastewater storage device.

[0057] The refined solution was evaporated and concentrated in vacuo, the evap...

example 3

[0069] Get the sodium salt method waste water 1000L (pH is 7.8~9) after removing the vanadium chromium through filtering, be that its pH=5.1 is adjusted by the industrial sulfuric acid of 40% with concentration, the processing speed of 10L / h is according to according to the method of the present invention processing method.

[0070] The main parameters are:

[0071] At normal pressure, the sodium sulfate crystal evaporation crystallization temperature is 91-97°C, the stirring speed is 380rpm, the concentration ratio is 8.5:1, the crystallization time is 50 minutes, and the heat preservation and suction filtration temperature is 90°C to obtain anhydrous sodium sulfate and ammonium-enriched liquid.

[0072] Cool the ammonium-enriched liquid to 9°C, and after natural crystallization at constant temperature for 3 hours, perform suction filtration to obtain double salt residue and refined liquid. The double salt slag is directly redissolved in the initial wastewater storage device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com