Hydraulic-loom wastewater treatment recycling method

A technology for water jet loom and wastewater treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Environmental secondary pollution, difficult to remove oil and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

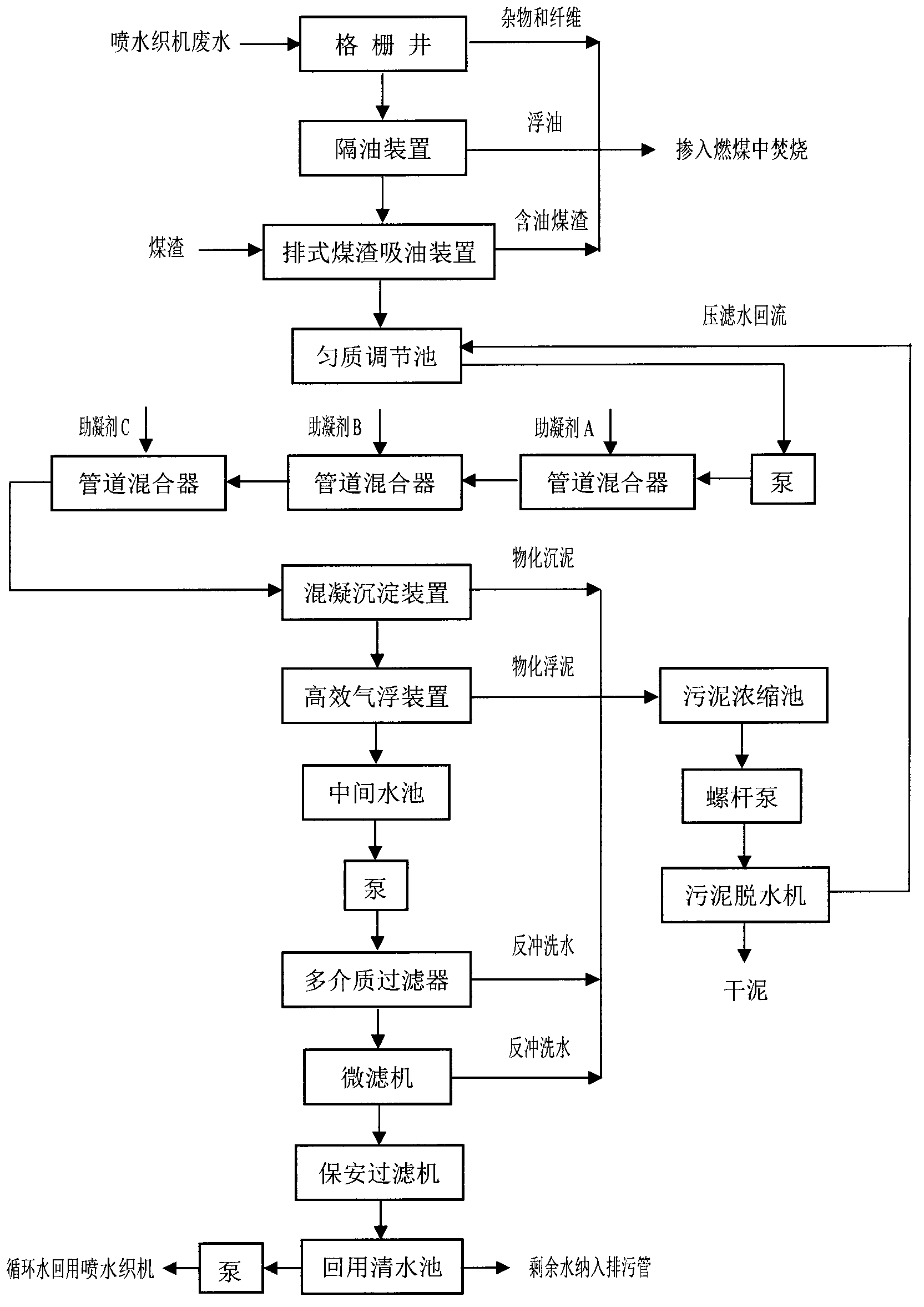

[0021] In the embodiment of wastewater treatment and reuse in a water jet loom workshop, the wastewater treatment flow rate is 1200m 3 / d, the CODcr concentration is 500mg / l, the pH value is 6.5, the SS concentration is 420mg / l, and the chromaticity is 360 ° (dilution multiple), adopt the present invention as figure 1 Shown a kind of water jet loom waste water treatment reuse method, concrete steps are as follows:

[0022] The first step is to pre-treat the waste water from the water jet loom for degreasing, and the waste water from the water jet loom enters the grille to filter out the large particles of debris and fibers, and then the waste water flows into the oil separator to remove the slick oil , and then enter the row-type cinder oil absorption device to absorb oily substances, and then collect the sundries, fibers, floating oil and oily cinders through the pipeline, and mix them into the coal-fired boiler for incineration. On the one hand, the boiler can increase the c...

Embodiment 2

[0028] The present invention is through the optimal combination of water jet loom wastewater treatment process, referring to the attached figure 1 The treatment and reuse process is determined as follows: firstly, the oil, large colloidal particles and sundries are basically removed through degreasing pretreatment,

[0029] It effectively reduces the load of subsequent physical and chemical processing and physical processing, and improves processing efficiency.

[0030] By adding coagulant aids sodium hydroxide, ferrous sulfate and polyacrylamide to the three sets of pipeline mixers respectively, the dosages are about 0.2%, 0.2% and 0.03% of the waste water, and through the flow water in the pipeline mixer Stirring at the flow rate will cause the negatively charged colloidal particles in the neutralized water to become unstable and adsorb with other colloidal particles in the water to form larger particles. The water flows into the reaction tank of the coagulation and sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com