Method for promoting resistant starch content of starch

A technology for the content of resistant starch and amylose, which is applied in the field of food processing and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

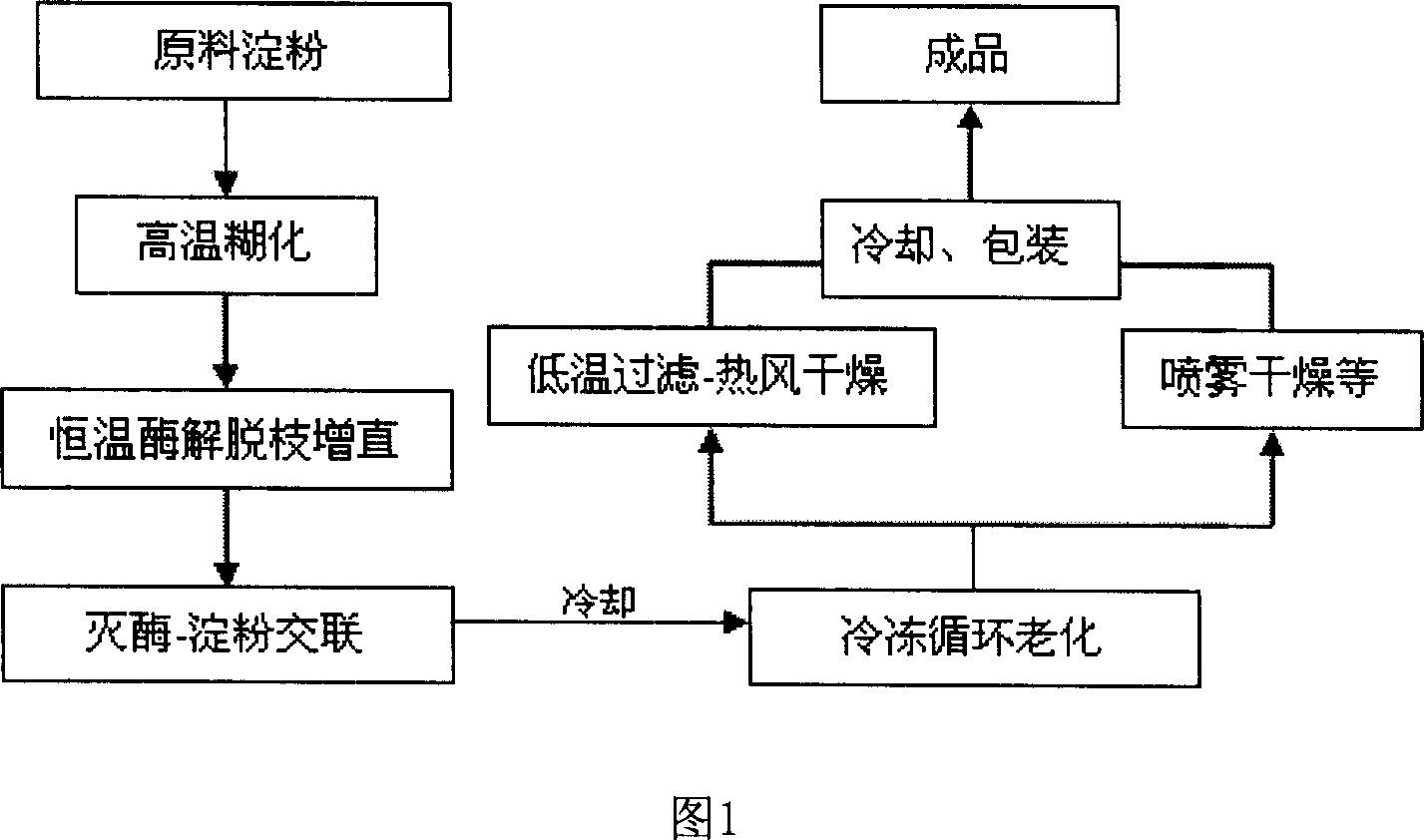

[0017] The scheme of the present invention is described in detail below according to the accompanying drawings.

[0018] 1. High-temperature gelatinization: The raw starch requires that the amylose content is greater than 10% after being determined by the lye dispersion method, such as corn starch, mung bean starch, highland barley starch, kudzu root starch, sorghum starch, lotus root starch and other planted and wild resource starches. The raw starch is formulated into a starch emulsion at a certain concentration in an aqueous solution. The concentration is low, the transmission and evaporation in the subsequent process will lead to high energy consumption; the concentration of starch emulsion is high, the solution is viscous, the transmission is difficult, the reaction is incomplete, and the heat conduction is difficult; the concentration of starch emulsion is 3%-25%. . Starch emulsion needs to be fully gelatinized under heating conditions, so that starch granules absorb wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com