Impurity removing refining process of high pure bismuth

A high-purity and technological technology, applied in the field of high-purity bismuth removal and refining process, can solve the problems of reducing the recovery amount and recovery rate of bismuth refining, slowing down the diffusion speed, removing unfavorable impurities, etc. The effect of large contact area and improving bismuth recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

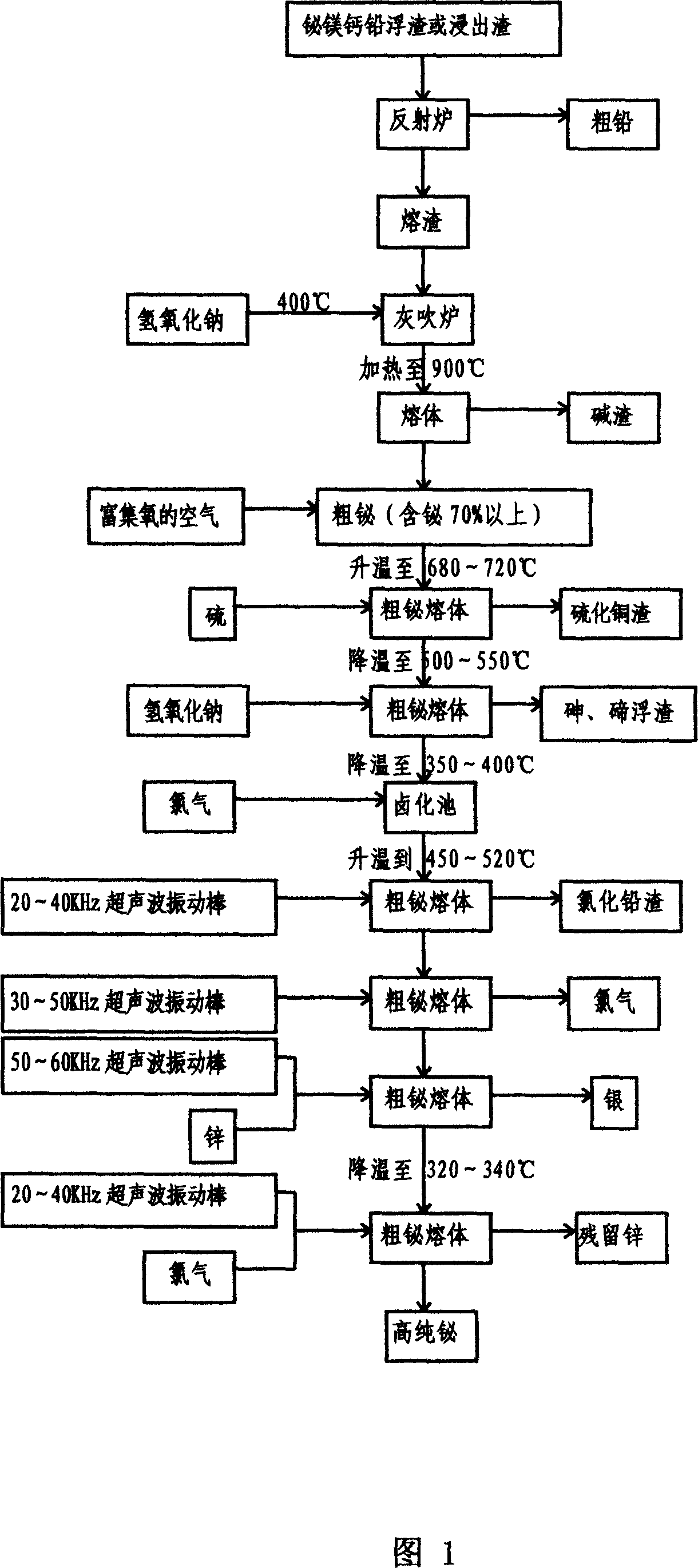

[0015] Below in conjunction with the production process flowchart of accompanying drawing, the present invention will be described in detail with specific embodiment:

[0016] The production process flow chart of the accompanying drawing describes a high-purity bismuth impurity removal and refining process, and its rough bismuth is produced according to the following process: first, smelting bismuth, magnesium, calcium, lead scum or leaching slag is put into a reverberatory furnace Heating, freeing lead, extracting crude lead; then putting the deleaded slag into the ash blowing furnace, adding molten sodium hydroxide at a temperature of 400°C, melting and heating to 900°C, blowing in and stirring with oxygen-enriched air melt, and then remove the alkali slag to produce coarse bismuth containing more than 70% bismuth.

[0017] Its high-purity bismuth is produced according to the following process: melt the crude bismuth prepared above and raise the temperature to 680-720°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com