Surface nano tip array and its preparing method

A technology of nano cones and arrays, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of small production area, poor consistency and controllability, poor adhesion, etc., and achieve a wide range of applications and a small radius of curvature at the top Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

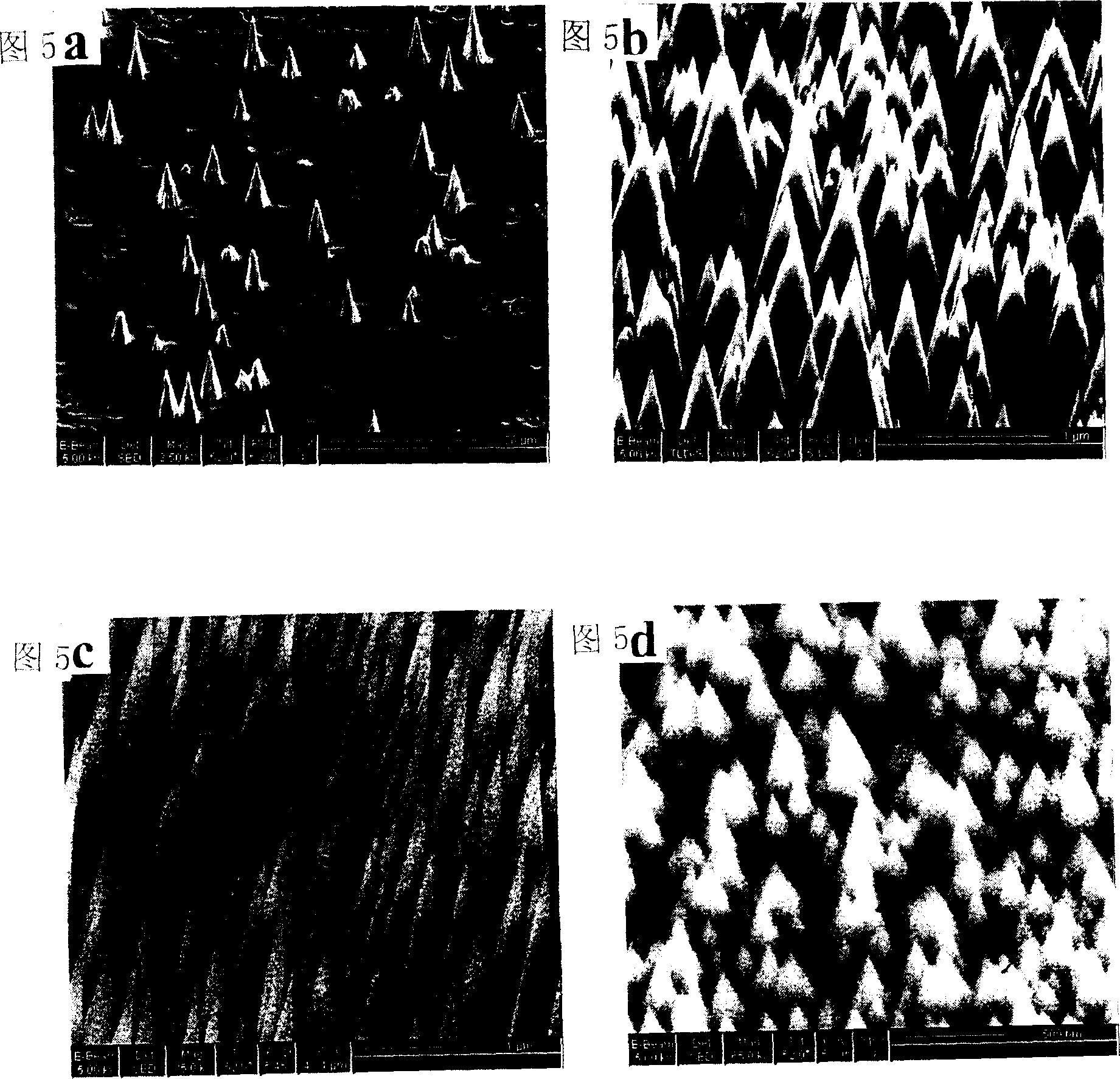

[0043] Referring to Fig. 5a, a diamond surface nanocone array is fabricated. The cone height of the nanocone array on the diamond surface is about 8-10 microns, the tip curvature radius is 5 nanometers, the aspect ratio is about 1600-2000, the bottom diameter is 1-2 microns, the cone angle is about 34°, and the cone density is 2× 10 6 cm -2 .

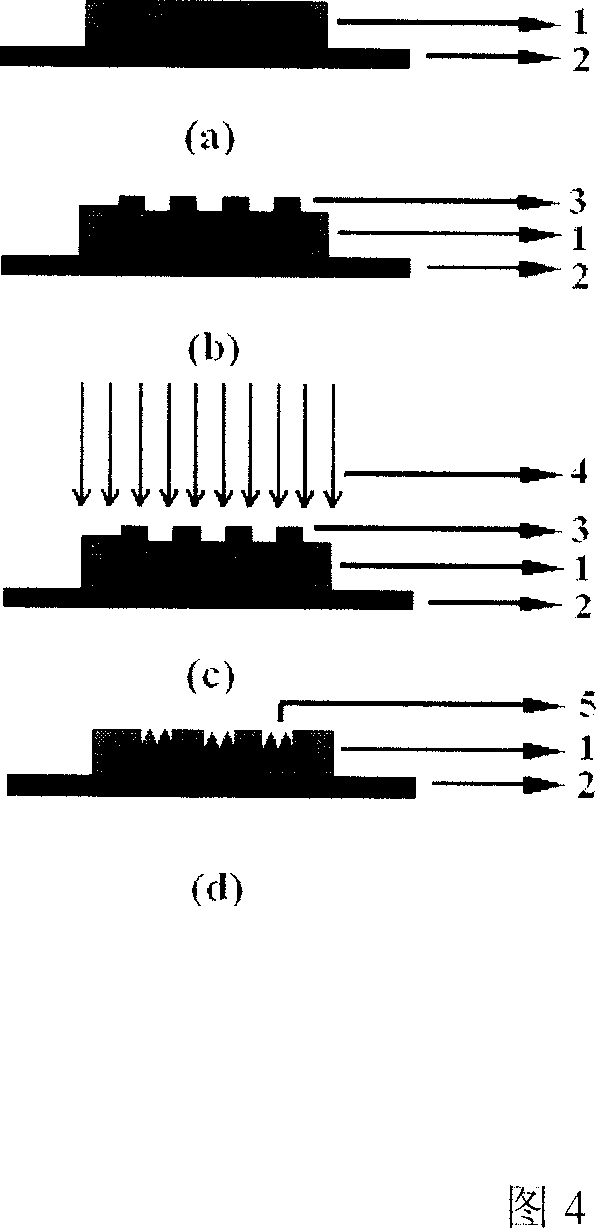

[0044] Referring to Fig. 4a-d, the specific method of the present invention is described in detail according to its process steps.

[0045] 1), using the hot wire CVD method to prepare a diamond thick film with a thickness of about 15 microns on a 3cm×2cm n-type silicon wafer as the etching substrate 1, and ultrasonically treat the silicon wafer for 1 hour by diamond powder grinding before growing, and place The cleaned substrate material 1 is placed on the stainless steel round support 2, and placed in the CVD equipment, and vacuumed to 10 -2 The specific parameters of Torr’s hot wire CVD method growth are as follows: air pressure:...

Embodiment 2

[0053] The specific structure of the diamond surface nanocone array 5 of the present embodiment is referring to Fig. 5 (b); The height of the diamond cone tip is about 1 micron, the radius of curvature of the tip is 2 nanometers, the aspect ratio is about 500, and the bottom diameter is 0.3 micron. Density is 5×10 8 cm -2 .

[0054] Made according to the preparation process of Example 1, the difference between this example and Example 1 is as follows: the volume ratio of methane / hydrogen gas during plasma 4 etching: 1.5 / 98.5, the pressure is 20 Torr, and the time is 1 hour.

Embodiment 3

[0056] The specific structure of the nanocone array 5 on the porous silicon surface of the present embodiment is referring to accompanying drawing 5 (c), and the height of the cone tip is about 2 microns, the radius of curvature of the tip is 5 nanometers, the aspect ratio is about 400, and the diameter of the bottom is 0.3 microns. Density is 4×10 8 cm -2 .

[0057] The difference with embodiment 1 is as follows:

[0058] 1. The present embodiment adopts the porous silicon substrate 1 prepared by the electrochemical etching method, and its specific preparation method is as follows: n-type silicon (6-9Ω.cm): 1cm×1cm, electrochemical etching solution: C 2 h 5 OH / HF (49%) is 1:1 (volume ratio), corrosion time: 15 minutes, corrosion current: 20 mA.

[0059] 2. The volume ratio of methane / hydrogen gas during plasma 4 etching: 2 / 98, the gas pressure is 20 Torr, and the time is 2 hours; due to the good conductivity of porous silicon, this embodiment does not use fine Pt metal wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com