System and method for agglomerating particulate matters through ultrasonic atomization of charged turbulence

A technology of agglomerating particles and ultrasonic waves, which is applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problem of not considering the bonding efficiency of particle surface bonding characteristics, unfavorable fluid flow in layout, and unsatisfactory agglomeration effect, etc. It can improve the surface adhesion characteristics, reduce the small eddy disturbance, and improve the collision probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

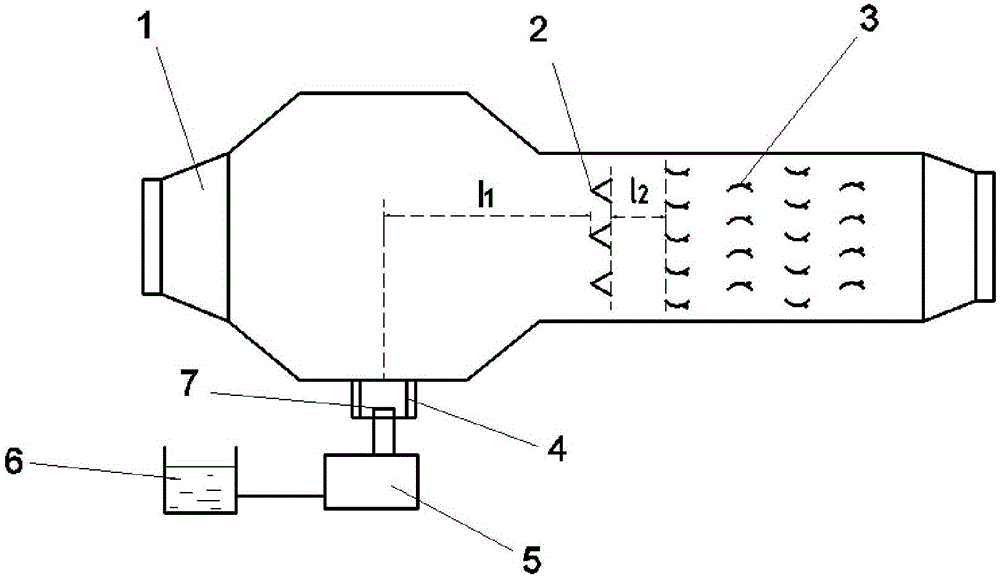

[0040] The present invention is a system for agglomerating particulate matter using ultrasonic atomization charging turbulent flow, which includes the following parts: the main body of the system is a rectangular structure, and the overall flow channel design is used. After being charged, it is sprayed into the flow channel; the pre-mixing section 2 and the turbulent agglomeration section are arranged downstream, the pre-mixing section 2 is used to produce large-scale turbulent flow, and the turbulent agglomeration section is used to mix incoming particles, and further generate mixing that takes into account both large and small turbulence Flow; Among them, in use, the size and spray volume of the spray port should be consistent with the fluid flow rate, flow rate and other conditions, and the...

PUM

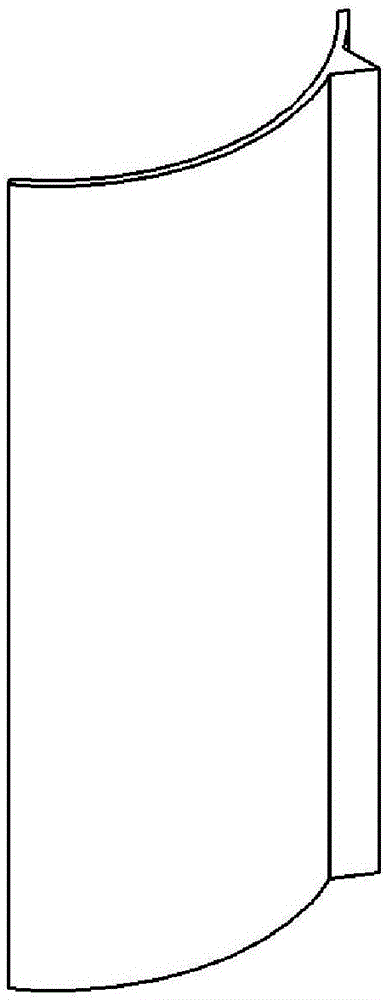

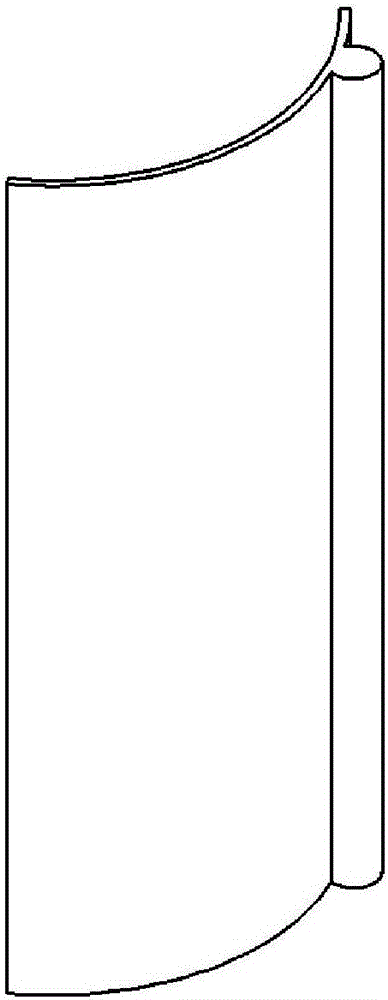

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com