Seed crystal for growth of silicon carbide single crystal, process for producing the same, and silicone carbide single crystal and process for producing the same

A technology of silicon carbide single crystal and manufacturing method, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as reduced effect and reduced gas barrier property, and achieves suppression of crystal defects, excellent gas barrier property, and gas barrier properties. High barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

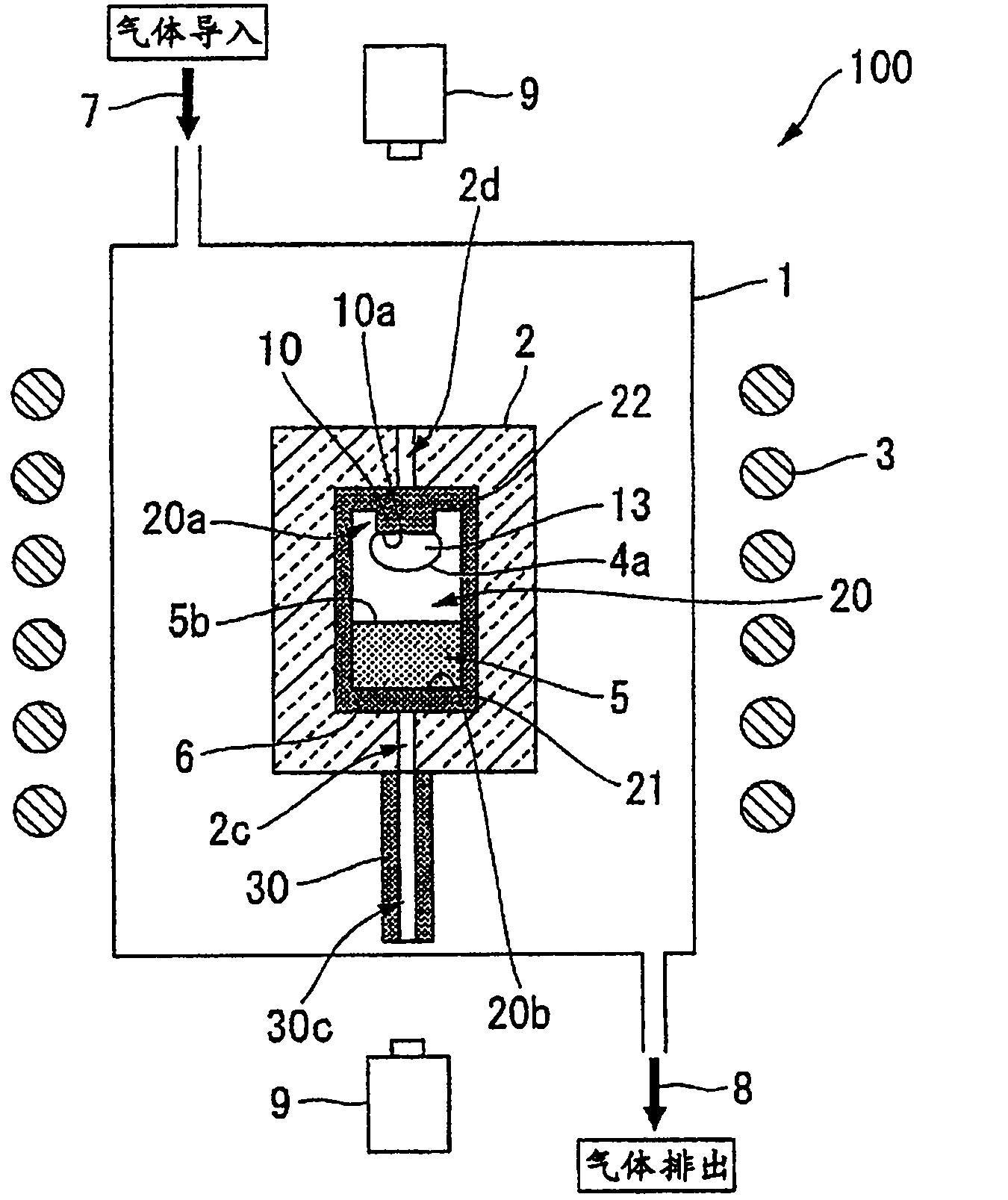

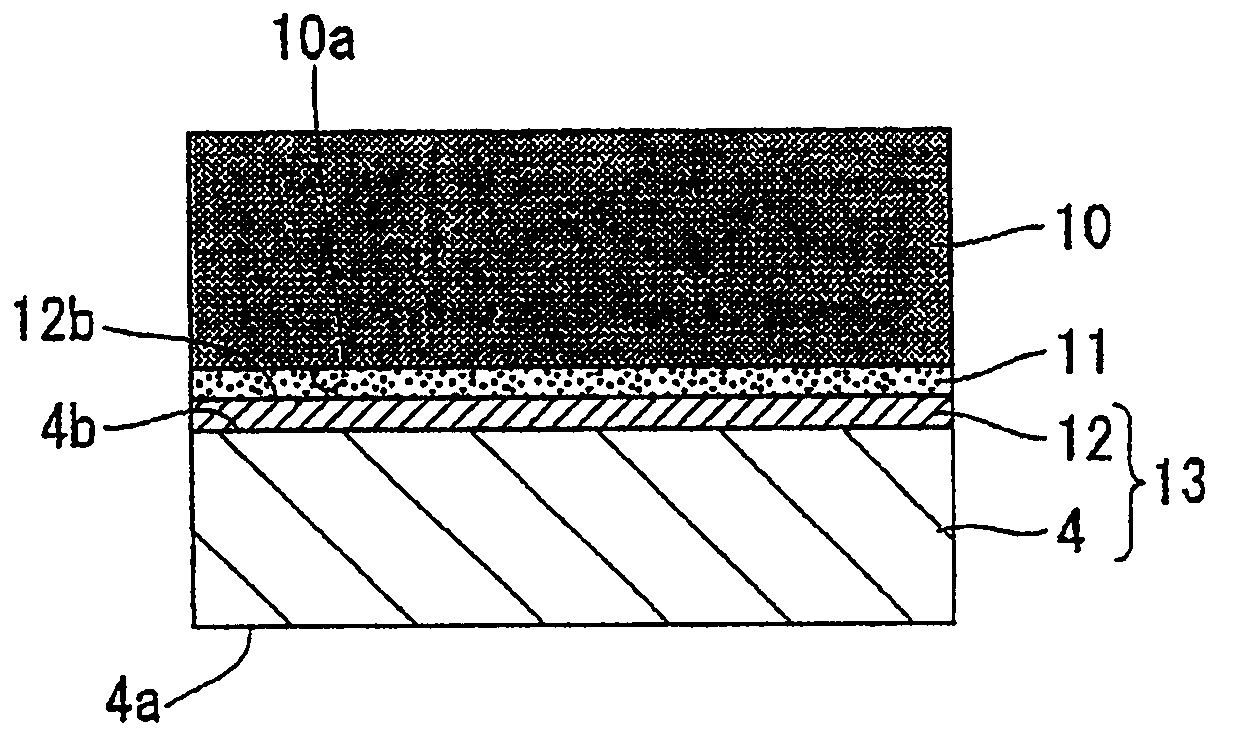

[0045] figure 1 It is a figure for demonstrating an example of the seed crystal for silicon carbide single crystal growth which is embodiment of this invention. It is a schematic cross-sectional view showing an example of a crystal growth apparatus in which a seed crystal for growing a silicon carbide single crystal according to an embodiment of the present invention is arranged.

[0046] Such as figure 1 As shown, the crystal growth apparatus 100 is schematically configured by arranging a graphite crucible 6 covered with a heat insulating (heat insulating) material 2 inside a vacuum container 1. A seed crystal 13 for growing a silicon carbide single crystal according to an embodiment of the present invention is bonded to one surface 10a of the protruding portion 10 of the cover 22 .

[0047] As the material of the vacuum vessel 1, a material capable of maintaining a high vacuum is preferably used, for example, quartz, stainless steel, and the like.

[0048] In addition, as...

Embodiment 1

[0123] First, prepare a substrate with an area of about 1.5cm 2 , a silicon carbide seed crystal substrate composed of 4H-silicon carbide single crystal with a thickness of 0.3mm, which was washed with a sulfuric acid-hydrogen peroxide mixed solution at 10°C for 10 minutes, washed with ultrapure water for 5 minutes, and ammonia- Wash with hydrogen peroxide mixed solution for 10 minutes, wash with running water for 5 minutes with washing ultrapure water, wash with hydrochloric acid-hydrogen peroxide mixed solution for 10 minutes, wash with running water for 5 minutes with washing ultrapure water, and then wash with HF solution. Then, after oxidizing the surface at 1200°C, HF cleaning was performed again.

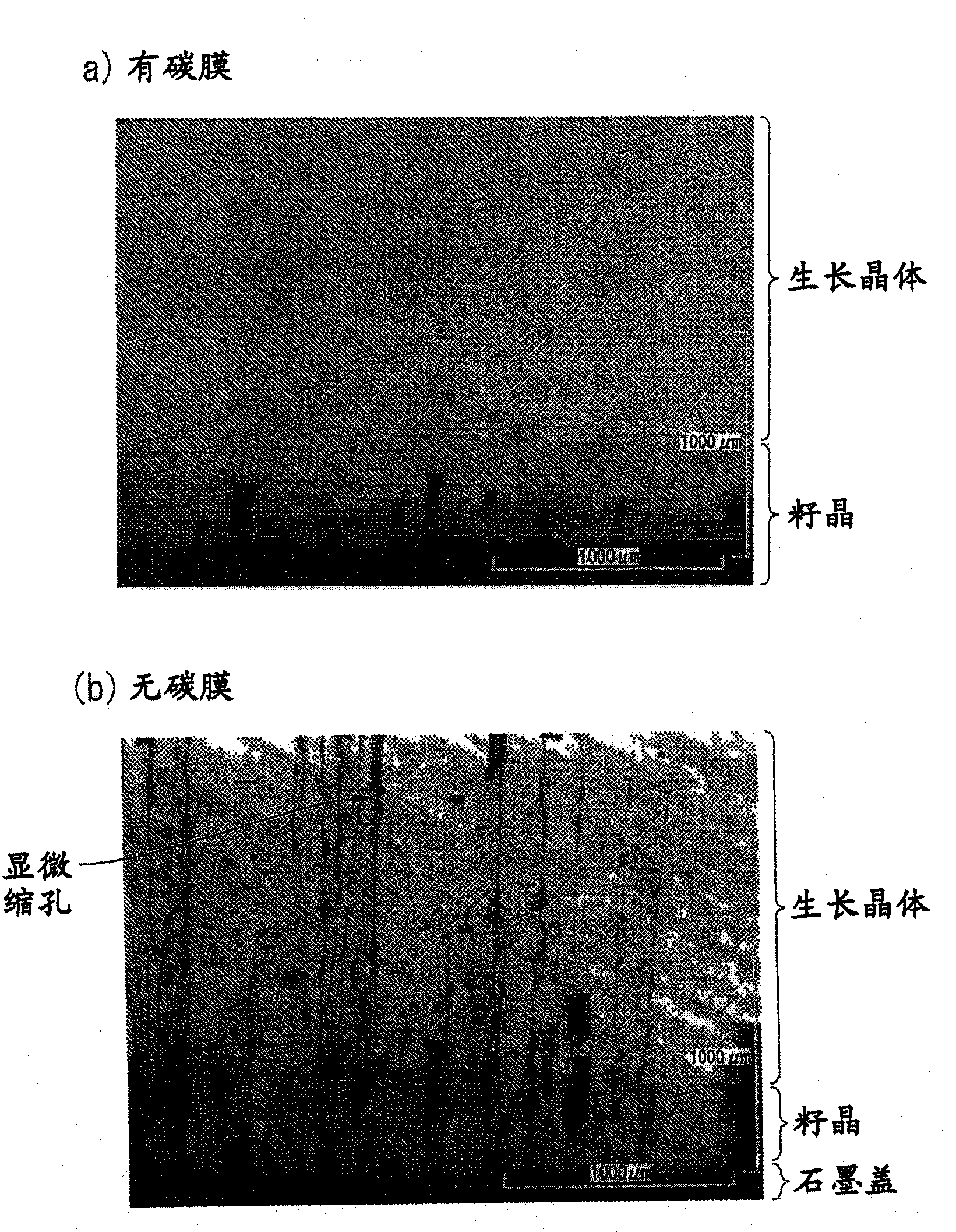

[0124] Next, a carbon film was formed on the (000-1) surface of the seed crystal substrate to form a silicon carbide single crystal growth seed crystal. As a film-forming method of the carbon film, a DC discharge sputtering method was used. The film was formed by sputteri...

Embodiment 2

[0141] In addition to using: the (000-1) plane of a 4H-silicon carbide single crystal with a thickness of 0.8 mm is used as the growth plane, and the (0001) plane is used as the surface on the side in contact with graphite, and a carbon film is formed on the (0001) plane. A silicon carbide single crystal was formed in the same manner as in Example 1 except for a growth seed crystal composed of a silicon carbide single crystal.

[0142] The obtained silicon carbide single crystal was cut parallel to the growth direction, and the cut surface was observed with a microscope. As in Example 1, substantially no void-like defects occurred in the silicon carbide single crystal.

[0143] From this, it was confirmed that even when the polarities of the two surfaces of the seed crystal made of silicon carbide are different, the effect of suppressing defects can be exhibited.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com