Oil based ink composition for inkjet printer

a technology of inkjet printer and pigment, applied in the field of oil based ink, can solve the problems of poor water resistance and light fastness of formed recorded image, inability to obtain high-quality print, and deterioration of recorded image, and achieve excellent dispersion stability and high discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

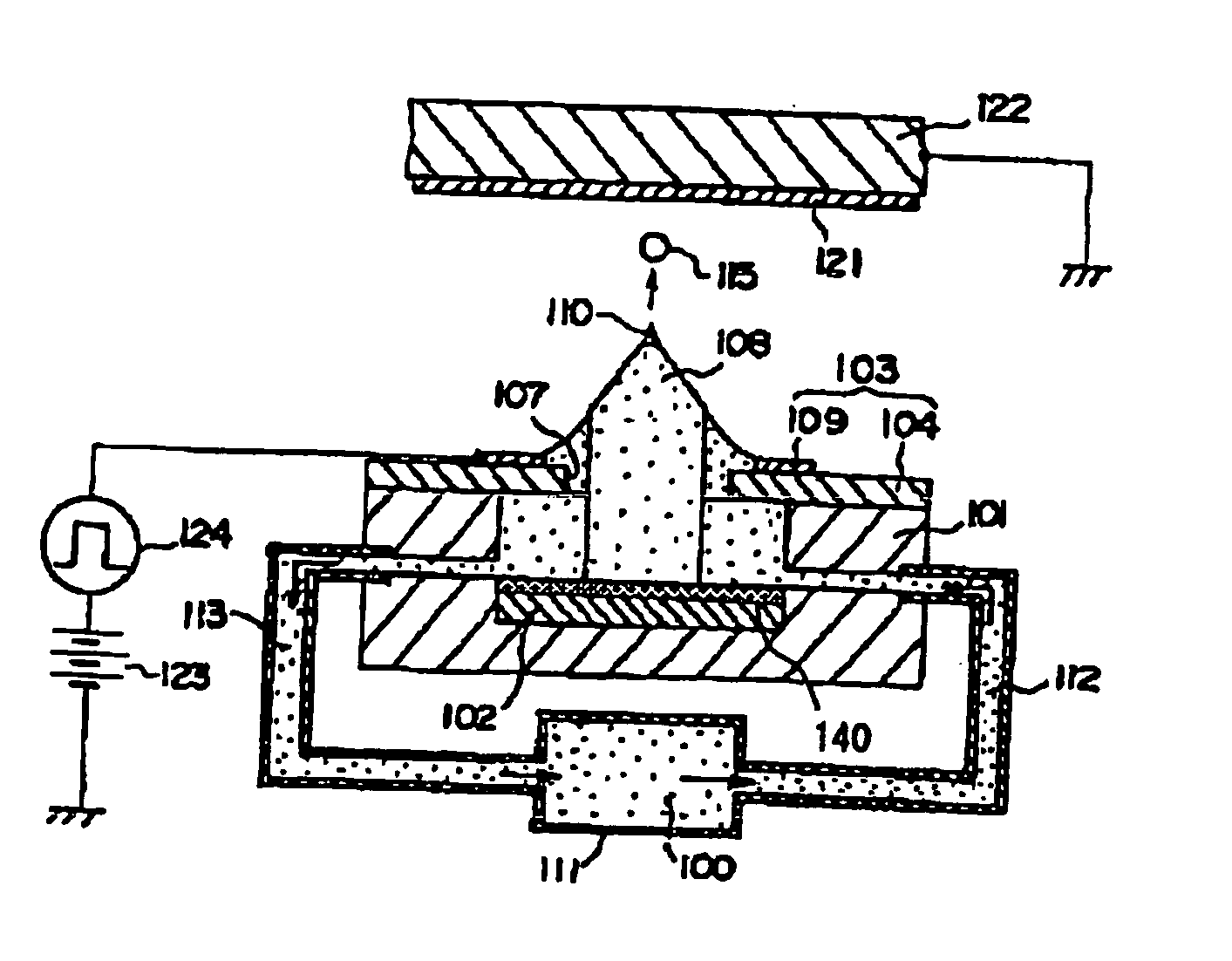

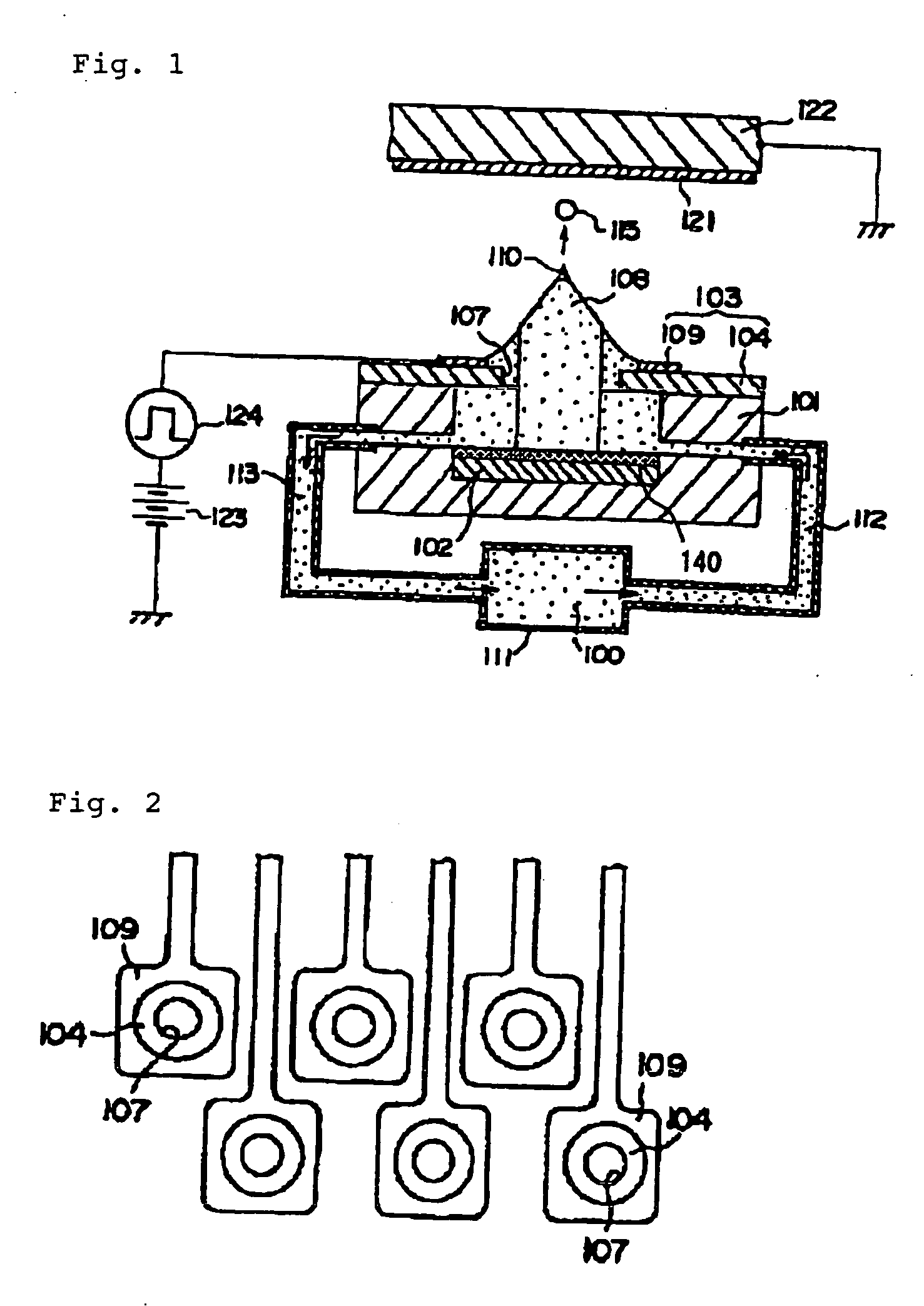

Image

Examples

preparation example 1

OF MACROMONOMER: MACROMONOMER (M-1)

[0150] A mixed solution of 100 g of octadecyl methacrylate, 2 g of thioglycolic acid and 200 g of toluene was heated to a temperature of 75° C. with stirring under a nitrogen gas stream. To the solution was added 1.5 g of 2,2′-azobis(isobutyronitrile) (abbreviated as AIBN), followed by reacting for 4 hours. Then, 0.5 g of AIBN was added thereto, followed by reacting for 3 hours, and further 0.3 g of AIBN was added thereto, followed by reacting for 3 hours. The reaction solution was cooled to room temperature, and 2.8 g of 2-hydoxyethyl methacrylate was added thereto. A mixed solution of 4.5 g of dicyclohexylcarbodiimide (abbreviated as DCC) and 10 g of methylene chloride was added dropwise thereto over a period of one hour. Then, 0.1 g of 4-dimethylaminopyridine and 0.1 g of tert-butylhydroquinone were added to the reaction solution, followed by stirring for 4 hours.

[0151] The crystals deposited were removed by filtration, and the filtrate was rep...

preparation examples 2 to 17

OF MACROMONOMER: MACROMONOMERS (M-2) TO (M-17)

[0152] Macromonomers (M-2) to (M-17) shown in Tables A and B below were prepared in the same manner as in Preparation Example 1 of Macromonomer except that a methacrylate monomer (corresponding to octadecyl methacrylate), a chain transfer agent (corresponding to thioglycolic acid), an initiator (corresponding to AIBN) and an unsaturated carboxylic acid ester (corresponding to 2-hydoxyethyl methacrylate) were changed to the corresponding compounds, respectively. The weight average molecular weight of each macromonomer obtained was in a range of from 4,600 to 31,000.

TABLE APreparationMacromonomerExample ofWeight AverageMacromonomerMolecular Weight)Chemical Structure of Macromonomer2M-2 (Mw = 12,600)3M-3 (Mw = 11,800)4M-4 (Mw = 16,500)5M-5 (Mw = 4,600)6M-6 (Mw = 9,800)7M-7 (Mw = 13,000)8M-8 (Mw = 14,400)9M-9 (Mw = 28,300)10M-10 (Mw = 21,400)

[0153]

TABLE BPreparationExample ofMacro-mono-Macro-mer (M)monomer (M)—X—11M-1112M-1213M-1314M-1415M...

example 1

[0160] A 20% solution prepared by dissolving Dispersion Stabilizer (P-1) described above in Isopar H by heating was used as a pigment dispersant. A mixture of 88.25 parts by weight of the pigment dispersant solution, 17.65 parts by weight of rosin ester resin-treated Microlith Black C-T (manufactured by Ciba Specialty Chemicals) as a black processed pigment and 29.4 parts by weight of Isopar H was blended together with 250 parts by weight of glass beads in a paint shaker (manufactured by Toyo Seiki Co., Ltd.) for 30 minutes. After separating the glass beads by filtration, the mixture was dispersed for 3 hours in a high-speed dispersion kneading machine (Dynomill KDL, trade name) at a rotation number of 3,000 rpm. Glass beads (MK-3GX) were used as media. The volume average particle size of pigment particles in the resulting dispersion was measured by ultra-centrifugal automatic particle size distribution analyzer (CAPA700 manufactured by Horiba, Ltd.). As a result, it was found that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com