A method of continuously producing resin-removed lignite wax and resin and a device thereof

A montan wax and resin technology, which is applied in natural resin refining, mineral wax recovery/refining, petroleum industry, etc., can solve the problems of high resin content, low degree of automation, high solvent consumption, etc., to ensure acid value and saponification value, Low solvent consumption and high desolventization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] The ambient temperature when the montan wax in step A enters the rotary extractor 1 is 10-20°C, and the temperature of the organic solvent is 13-17°C.

[0021] The weight ratio of the montan wax wax described in A step and fresh organic solvent is 1:1.

[0022] The degreased montan wax described in step B is melted and preheated to 90-100°C and sent to the desolventization device. The desolventization device is indirectly heated with saturated steam, directly stripped with superheated steam, and desolventized under an absolute pressure of 0.03Mpa.

[0023] The preheating temperature in step C is 90-100°C. The first steaming is the rising film long tube evaporation, and the second steaming is the falling film long tube evaporation, both of which are heated by saturated steam. Extraction; first steaming, second steaming, and stripping operations are evaporating and desolventizing under an absolute pressure of 0.03Mpa.

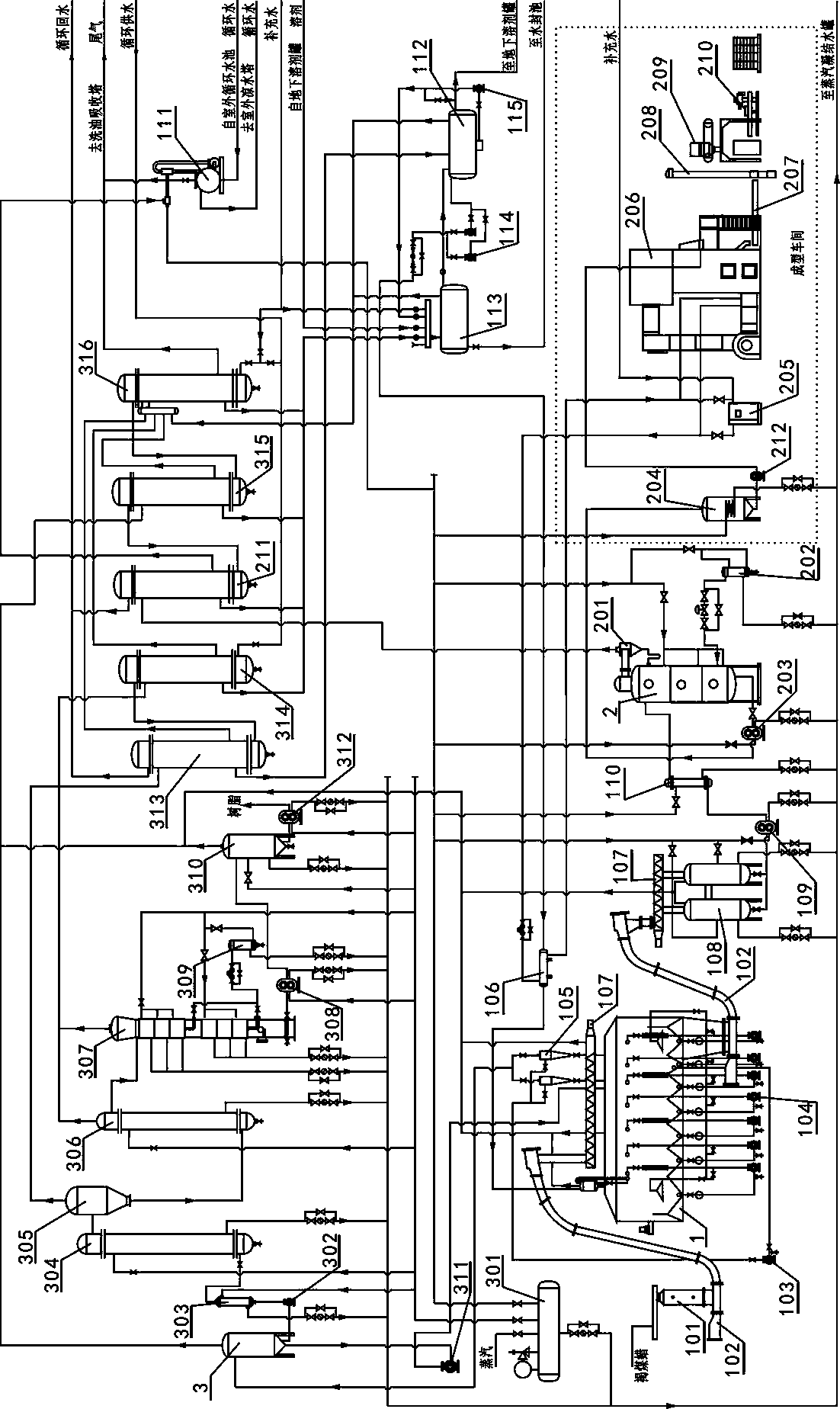

[0024] like figure 1As shown, the device of the pr...

Embodiment 1

[0031] With toluene as solvent, the weight ratio of montan wax to fresh organic solvent is 1:1.2. The montan wax with a particle size of 0.5~3mm is sent into the pan extractor 1 at a temperature of 10°C, and rotates with the operation of the pan extractor 1; the toluene in the solvent turnover tank 112 is cooled to 13°C, and then sprayed into the horizontal extraction device 1; toluene and montan wax countercurrent contact, the solvent circulation pump 104 will extract the toluene in the horizontal rotation extraction device 1 and then spray it into the horizontal rotation extraction device 1, so that the toluene is pressed Concentration gradient cycle contact with montan wax for mass transfer, such cycle leaching for 240min. The resin-rich toluene solvent is sent to the hydrocyclone 105 by the resin-rich solvent extraction pump 103, and the montan wax is separated and returned to the horizontal rotary extractor 1, and the rest enters the resin-rich solvent tank 3 for further ...

Embodiment 2

[0033] With ethyl acetate as the solvent, the weight ratio of montan wax to fresh organic solvent is 1:1. Send the montan wax with a particle size of 0.5~3mm into the pan extractor 1 at a temperature of 20°C, and rotate with the operation of the pan extractor 1; the ethyl acetate in the solvent turnover tank 112 passes through the solvent condenser 106 Cool down to 14°C, then spray into the rotary leaching device 1; ethyl acetate and montan wax are in countercurrent contact, and the solvent circulation pump 104 extracts the ethyl acetate in the rotary leaching device 1 and then sprays it into the rotary leaching device Device 1, make ethyl acetate circulate in contact with montan wax for mass transfer according to the concentration gradient, and leaching in this way for 150min. The resin-rich ethyl acetate solvent is sent to the hydrocyclone 105 by the resin-rich solvent extraction pump 103, and the montan wax therein is separated and returned to the horizontal rotation extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com