Patents

Literature

36 results about "Polyterpenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat shrink films and articles encapsulated therein

InactiveUS20090068486A1Synthetic resin layered productsDomestic containersPolymer scienceThin membrane

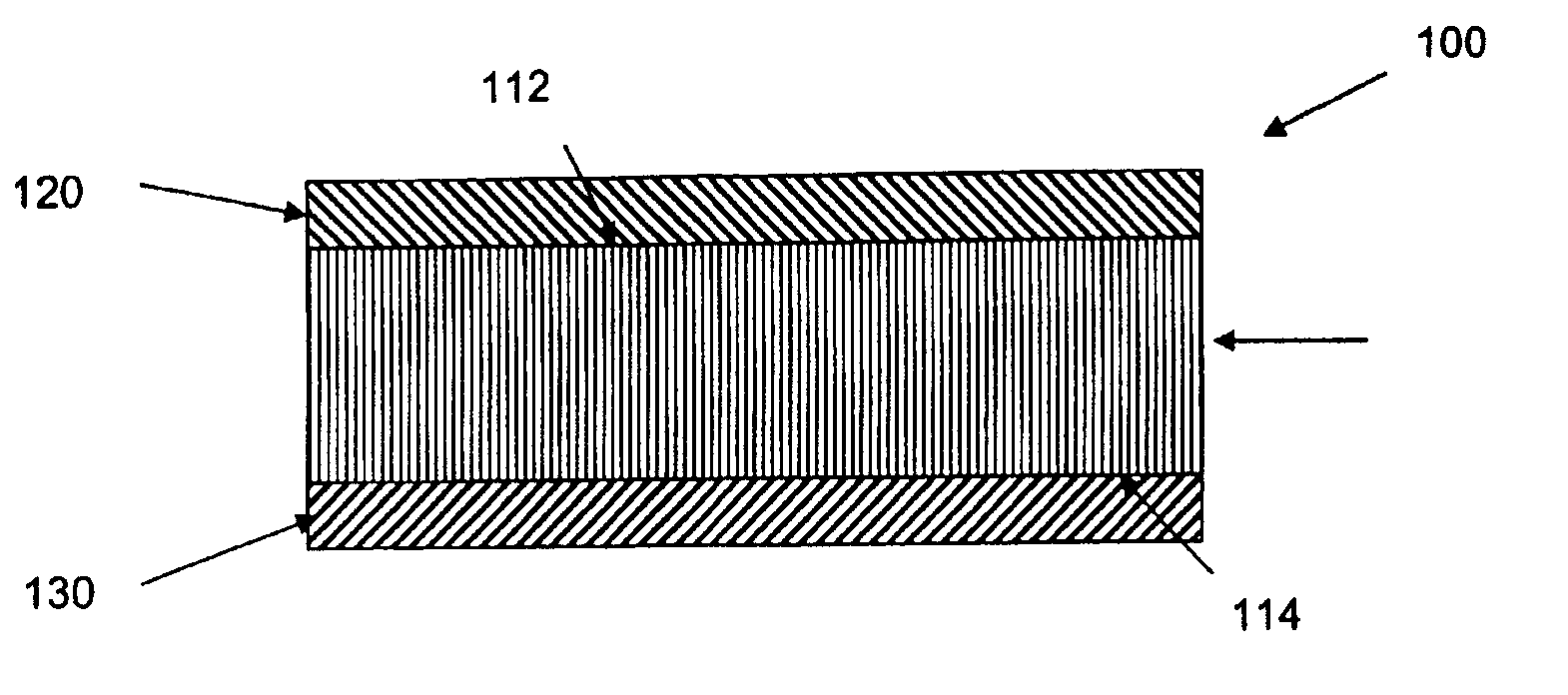

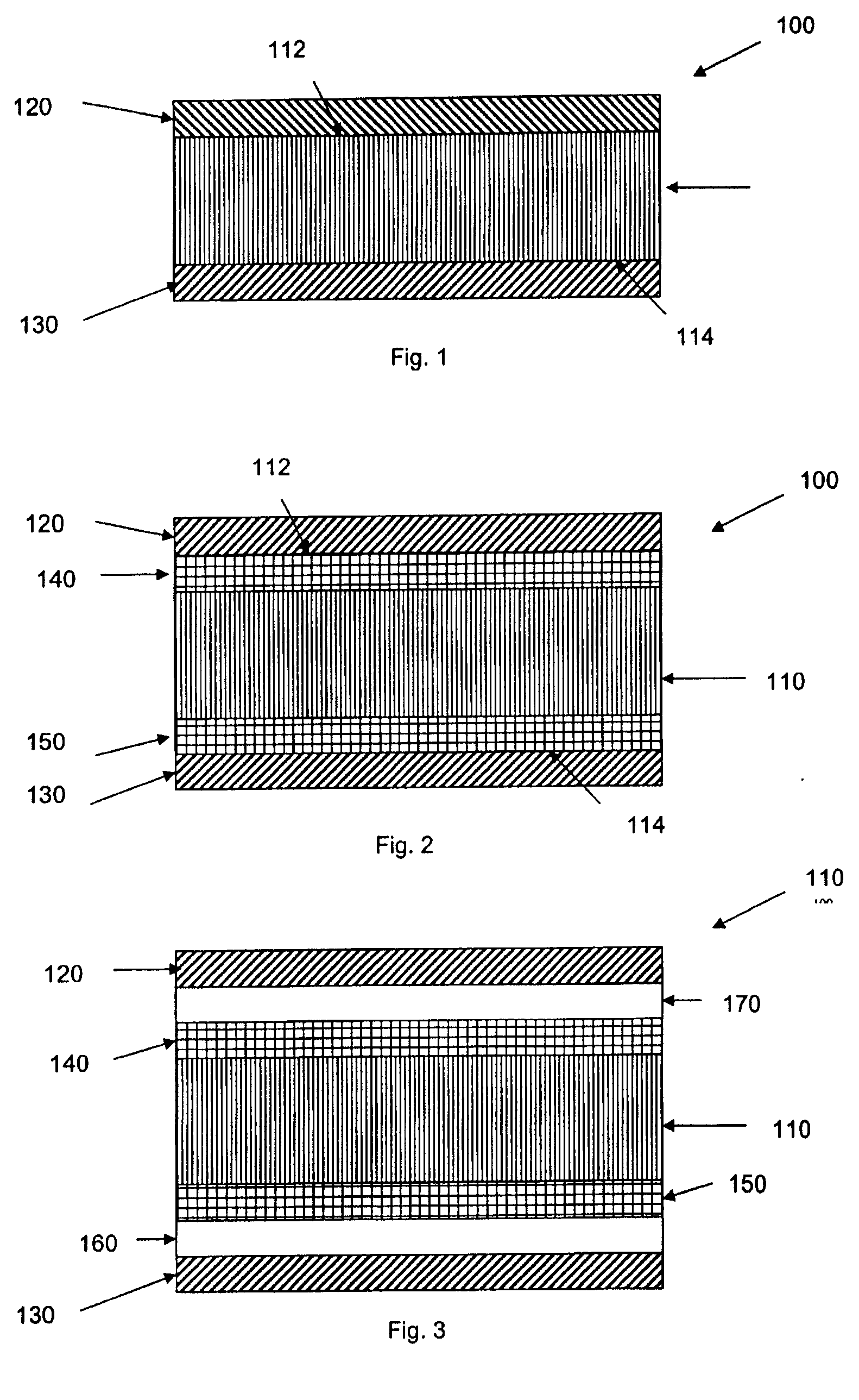

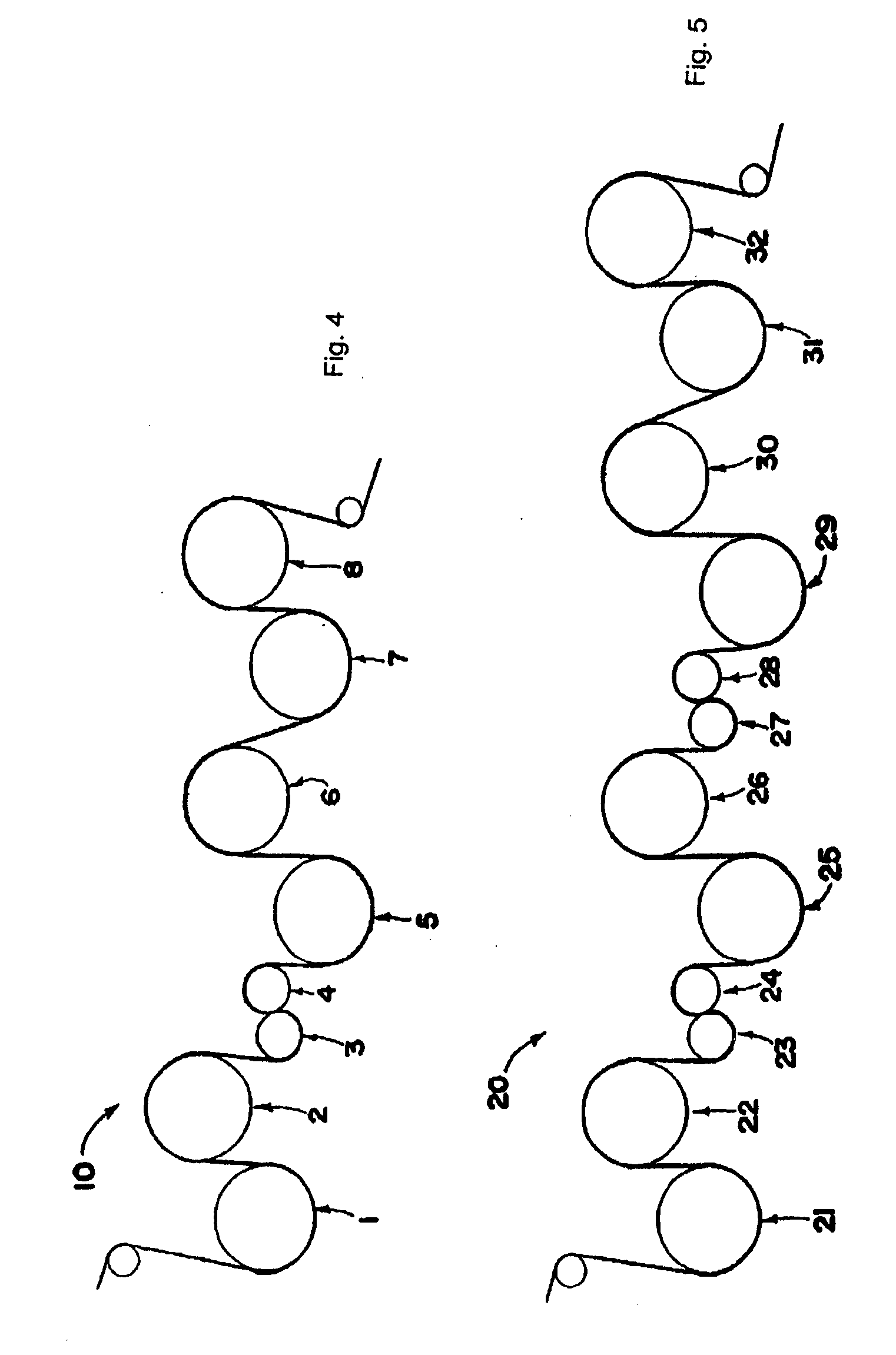

The present invention relates to a heat shrink film for encapsulating articles comprising a core layer having an upper surface and a lower surface, a first skin layer on the upper surface of the core layer, and a second skin layer underlying the lower surface of the core layer, wherein the core layer comprises a blend of (i) at least one polyterpene and (ii) a syndiotactic polypropylene or a cyclic olefin copolymer, wherein the ultimate shrinkage of the film is at least 25% at 135° C.

Owner:AVERY DENNISON CORP

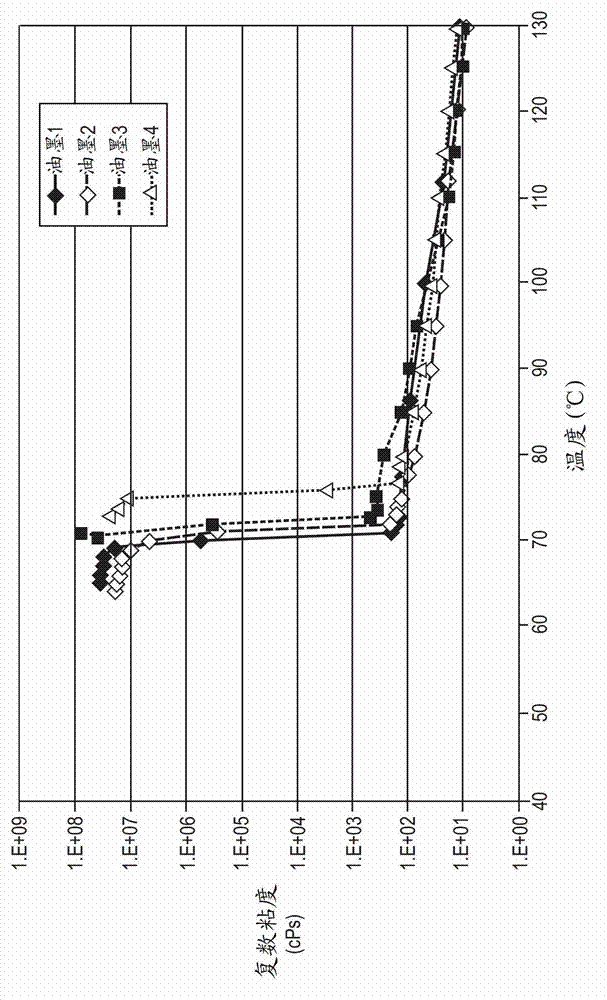

Pneumatic tire

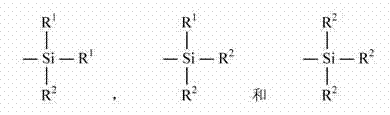

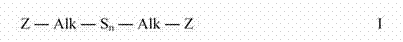

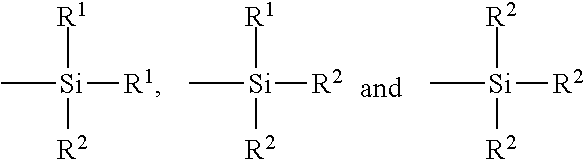

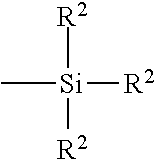

A pneumatic tire having a tread comprising a rubber composition comprising, expressed as parts by weight per 100 parts by weight of elastomer (phr), 100 phr of a solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 50 percent by weight, a vinyl 1,2 content of from 10 to 40 percent by weight based on the rubber weight, and a Tg of from -40ºC to -10ºC; 5 to 60 phr of a low PCA process oil having a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method; 90 to 150 phr of silica having a CTAB specific surface area (S CTAB ) of between 40 and 525 m 2 / g, and a BET specific surface area (S BET ) of between 45 and 550 m 2 / g; 10 to 20 phr of sulfur containing organosilicon compound; and 5 to 30 phr of a polyterpene resin is disclosed. Preferably, the rubber composition further comprises less than 10 phr of carbon black.

Owner:THE GOODYEAR TIRE & RUBBER CO

Pneumatic tire

The invention is directed to a pneumatic tire having a tread comprising a vulcanizable rubber composition comprising, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 100 phr of a solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 50 percent by weight, a vinyl 1,2 content of from 10 to 40 percent by weight based on the rubber weight, and a Tg of from about −40° C. to about −10° C.;(B) 5 to 60 phr of a low PCA process oil having a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method;(C) 90 to 150 phr of silica having a CTAB specific surface area (SCTAB) of between 40 and 525 m2 / g, a BET specific surface area (SBET) of between 45 and 550 m2 / g;(D) 10 to 20 phr of sulfur containing organosilicon compound;(E) 5 to 30 phr of a polyterpene resin, and(F) less than 10 phr of carbon black.

Owner:STEINER PASCAL PATRICK +4

Aqueous polymer dispersion and process

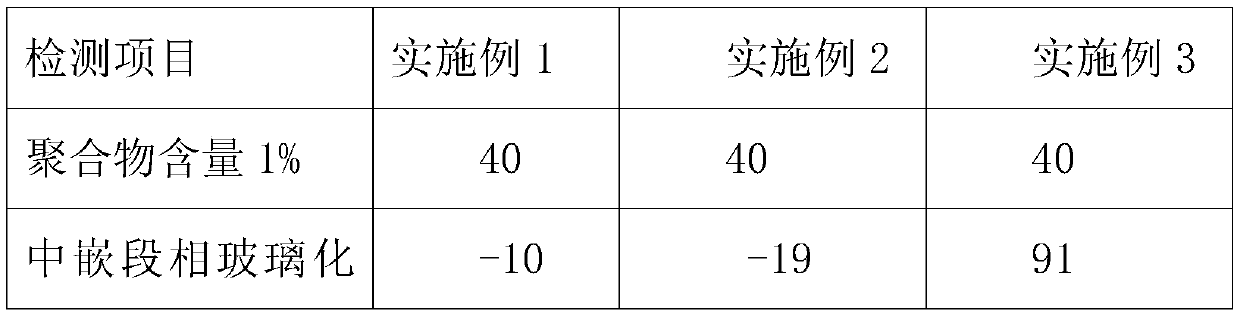

InactiveCN101522723AEx situ control chemistryEx situ control of physical propertiesCoatingsGraft polymer adhesivesTackifierPolymer chemistry

There is described a multi step process for preparing an aqueous dispersion of heterogeneous polymer particles by mini-emulsion polymerisation, the process comprising the steps of (I) (a) forming a mixture comprising: (i) water; (ii) at least one stabiliser (such as a surfactant and a hydrophobic co-stabliiser); (iii) at least one tackifier (such as polyterpenes, rosin resins and / or hydrocarbon resins); (iv) at least one +-,-ethylenically unsaturated monomer;, (b) applying high shear to the mixture from step (a) to form an essentially stable mini-emulsion comprising an aqueous continuous phaseand dispersed therein stabilised droplets of average diameter from about 10 to about 1000 nm, (c) polymerising the monomer(s) within the droplets in the presence of a free radical initiator; (d) adding further monomer to the dispersed phase to form a dispersion; then: (II) using the dispersion from step (I) as a seed to form a dispersion of heterogeneous polymer particles in a subsequent emulsionpolymerisation. The resultant tackified PSAs may have a core shell structure and are stable under high shear.

Owner:CYTEC SURFACE SPECIALTIES INC

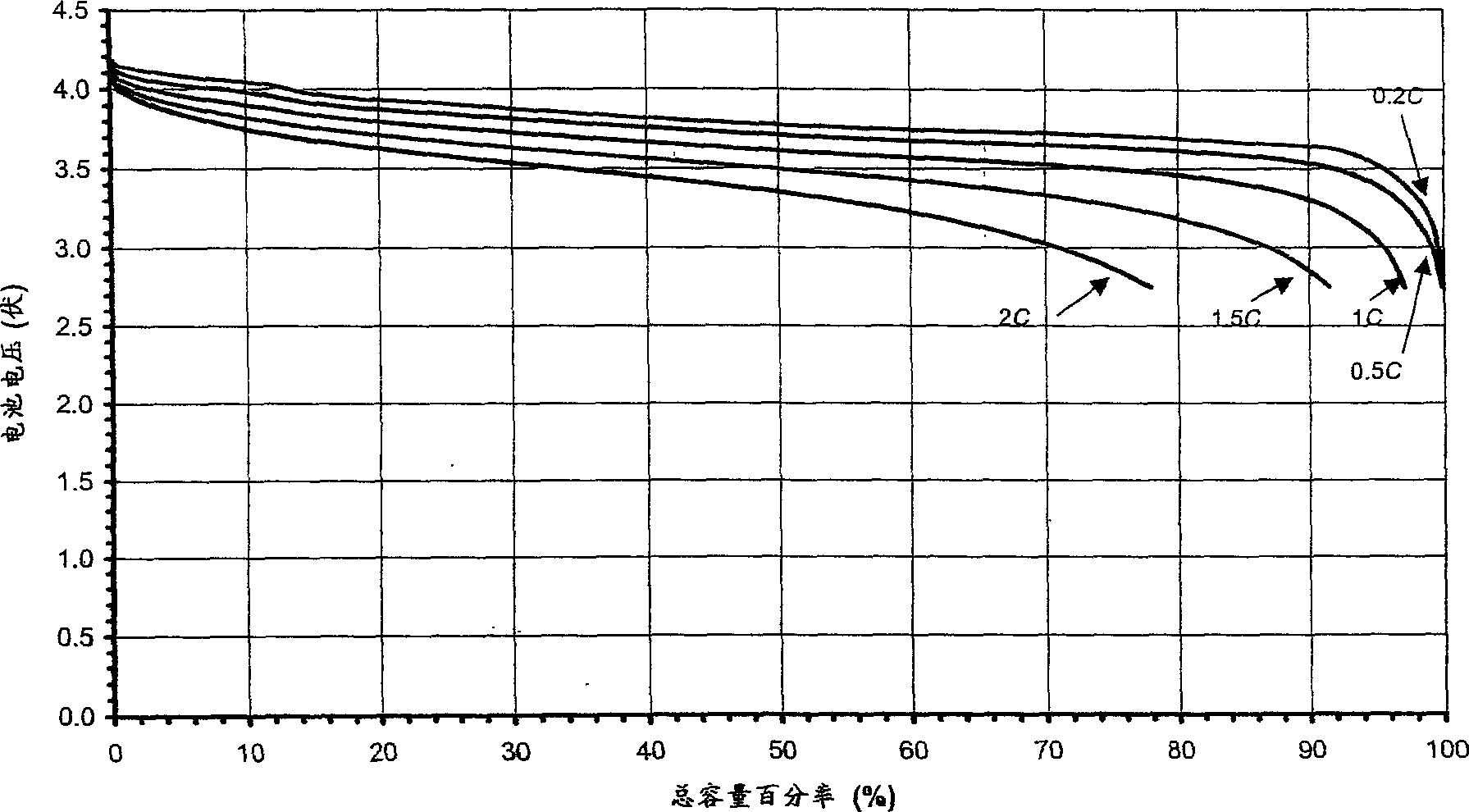

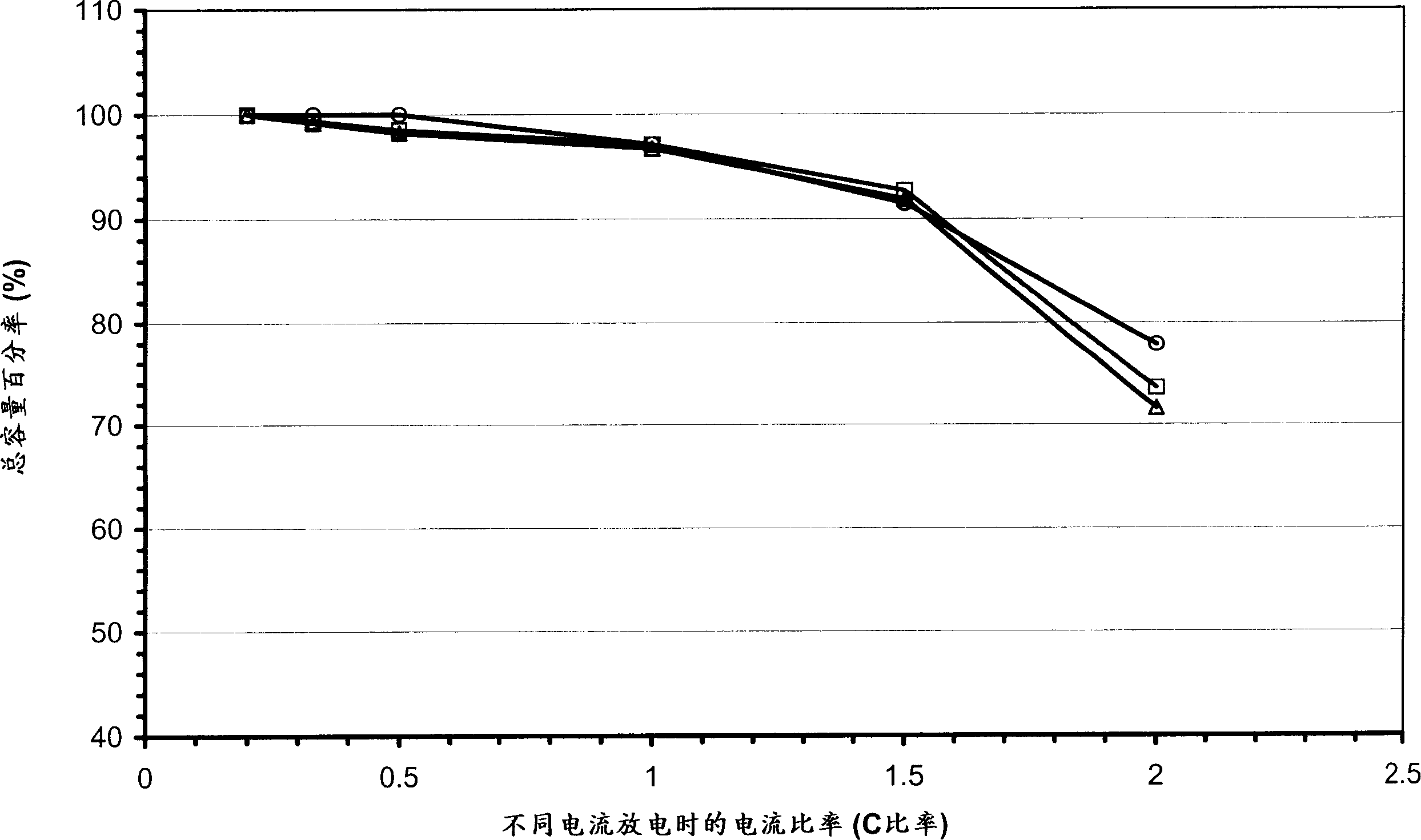

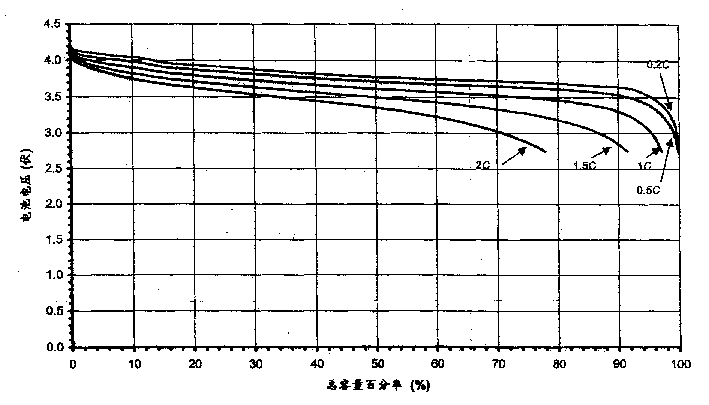

Heat activated microporous membrane and its application in battery

InactiveCN1439666AGood current charging and discharging abilityHigh porosityCell component detailsCalcium silicateFumed silica

PROBLEM TO BE SOLVED: To provide a porous membrane for use in fabricating a storage battery, and to provide a method for manufacturing the same.SOLUTION: The porous membrane comprises: (a) a hot melt adhesive agent such as poly(ethylene-vinyl acetate) or a poly(ethylene-alkyl acrylate) (b) an engineering plastic such as polysulfone, polycarbonate, or poly(styrene-methyl methacrylate). The membrane may also contain as required: (c) an adhesiveness providing agent such as an aromatically modified aliphatic hydrocarbon resin, aliphatic resin, hydrogenated alicyclic hydrocarbon resin, rosin resin, polyterpene resin, or PVdF-HFP; and / or (d) a filler such as fumed silica, alumina, titanium dioxide, molecular sieve, calcium carbonate, calcium silicate, glass, ceramic material, or polytetrafluoroethylene. The membrane is bonded to battery electrodes by thermal activation at approximately 35-125 °C and approximately 0.5-100 psi.

Owner:POLICELL TECH

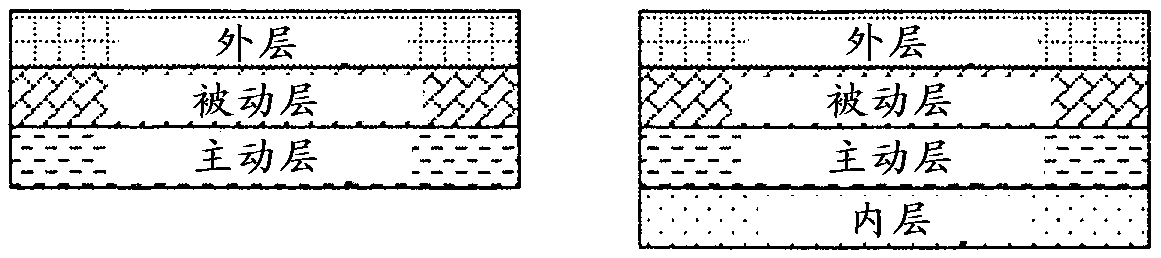

Oxygen barrier plastic material

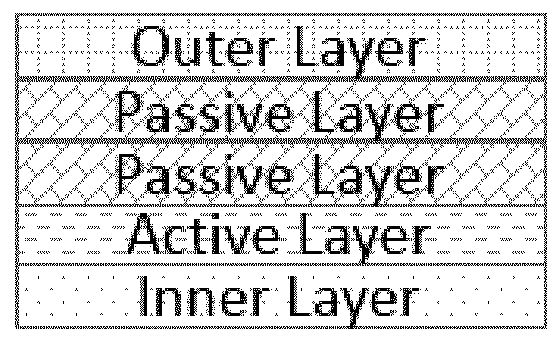

PendingCN109562609ASynthetic resin layered productsDomestic containersPolymer sciencePolyethylene terephthalate glycol

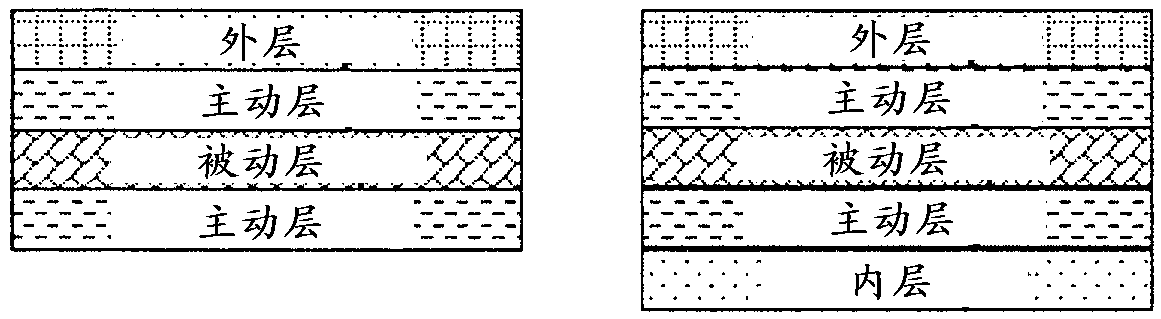

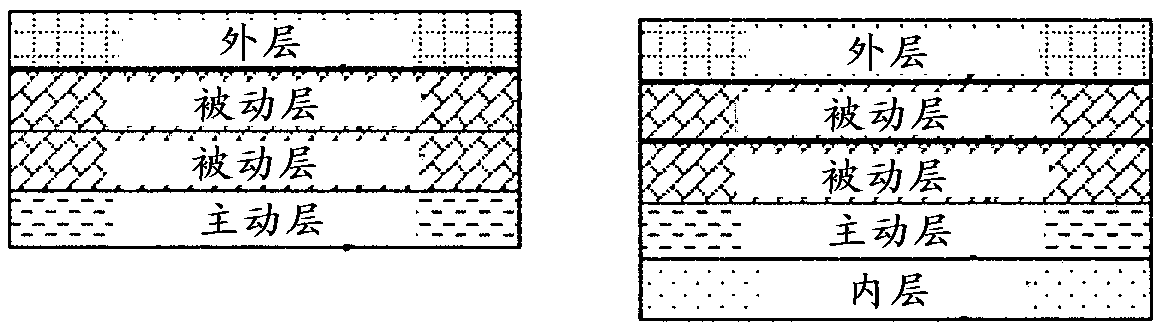

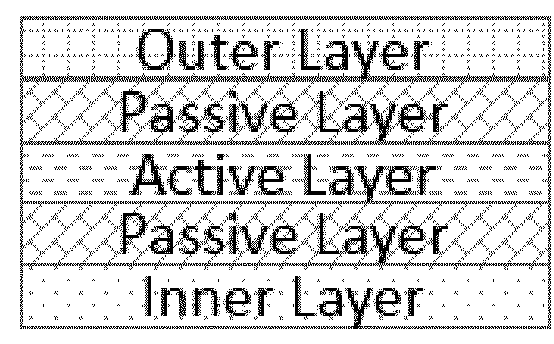

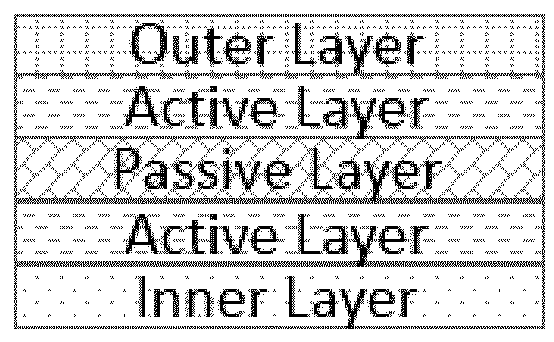

The invention relates to a multilayer packaging film comprising at least three different types of layers (A), (B), and (C): (A) is at least one outer layer, (B) is at least one passive oxygen barrierlayer, (C) is at least one active oxygen scavenging layer, characterized in that - the at least one outer layer (A) is a thermoplastic polymer; - the at least one passive oxygen barrier layer (B) is selected from the group consisting of ethylene vinyl alcohol copolymers, polyvinylchloride, copolymers of polyvinyl chloride, polyvinyl alcohol, polyvinylidene dichloride, copolymers of polyvinylidenedichloride, polyacrylonitrils, copolymers of polyacrylonitrils, polyethylene terephthalate, polyethylene naphthalate, polyethylenefuranoate, polysiloxanes, and polyamides; - the at least one active oxygen scavenging layer (C) comprises a) a plastic material which is a polyolefin, a polyolefin copolymer or a polystyrene, and additives (b) and (c), wherein b) is a polyterpenic resin; and c) is a transition metal catalyst.

Owner:CLARIANT PLASTICS & COATINGS LTD

Medical chewing gum

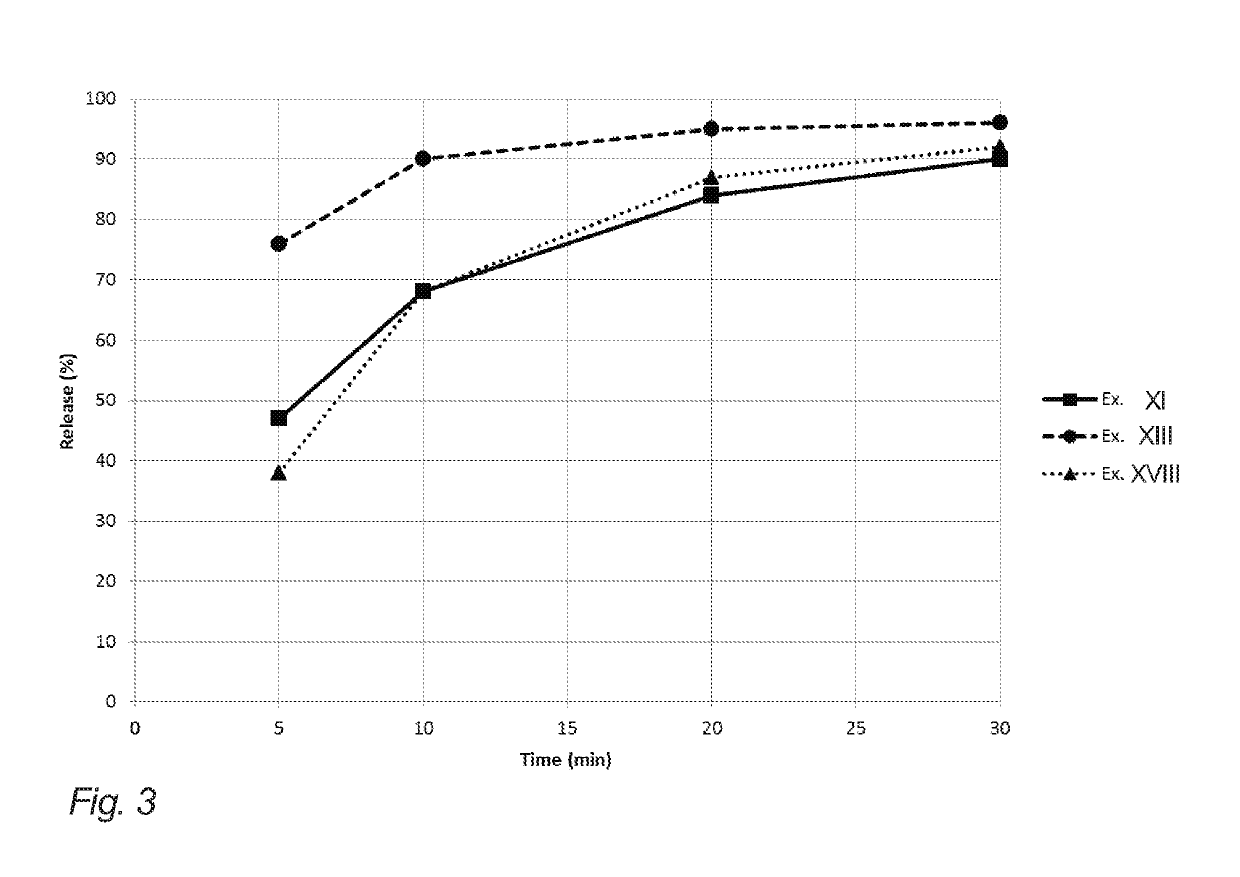

ActiveUS10426726B2Good reproducibilityOrganic active ingredientsNervous disorderPolyvinyl acetatePolymer science

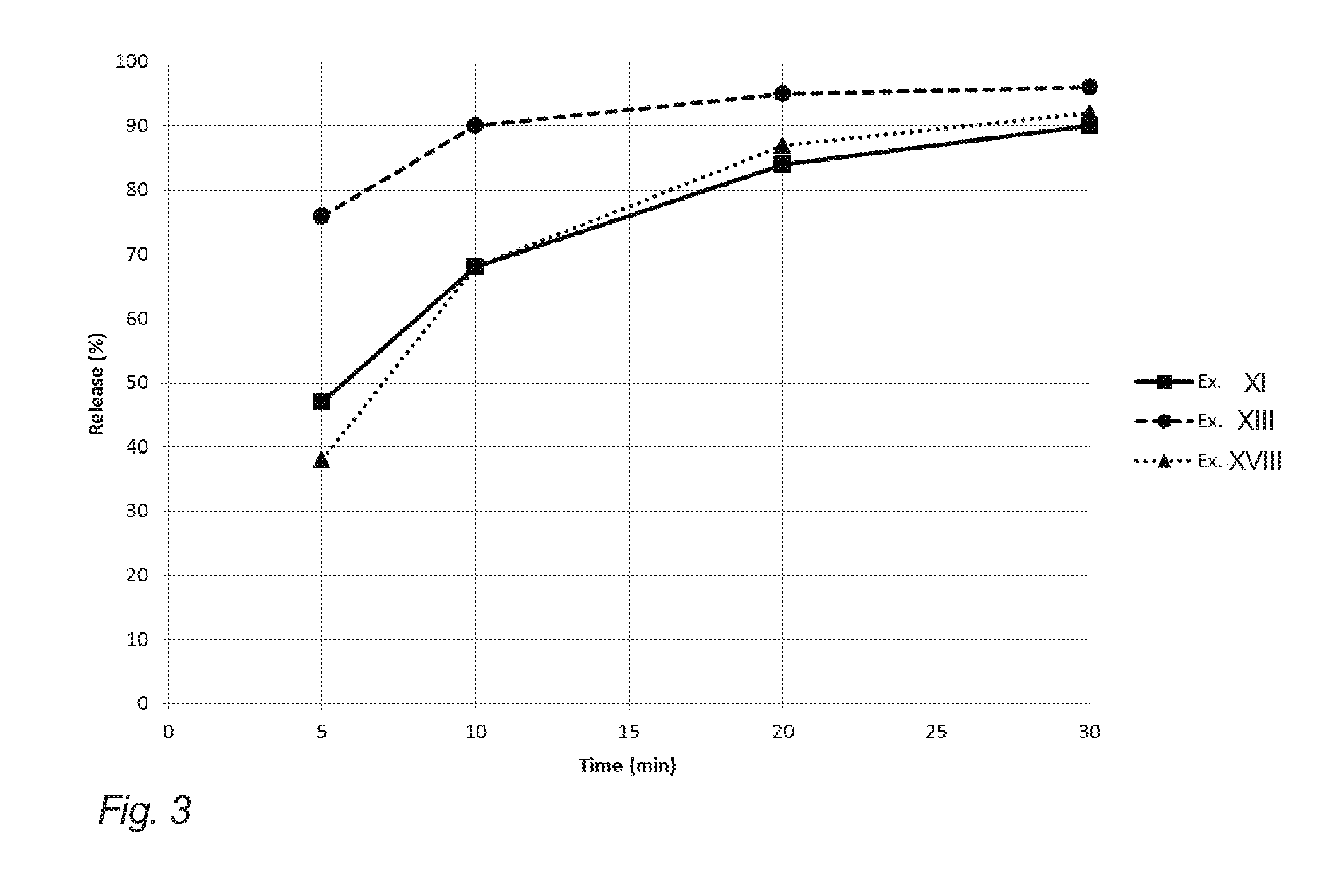

The invention relates to a medical chewing gum comprising gum base polymers and an active pharmaceutical ingredient, the gum base polymers comprising polyvinyl acetate and vinyl laurate-vinyl acetate copolymer in an amount of more than 90% by weight, wherein the gum base polymers include 20-95% by weight of polyvinyl acetate and -80% by weight of vinyl laurate-vinyl acetate copolymer, and wherein the chewing gum contains no polyterpene resins and no resins based on gum rosin, wood rosin or tall oil resin.

Owner:FERTIN PHARMA AS

Ester-soluble resin and preparation method thereof

InactiveCN101817965AImprove adaptabilityGood printing adaptabilityInksPolymer sciencePetroleum resin

The invention discloses an ester-soluble resin and a preparation method thereof. The ester-soluble resin comprises the following components in percentage by weight: 40 to 85 percent of a copolymer and 15 to 60 percent of a functional polymer, wherein the copolymer is copolymerized by 40 to 70 weight percent of a vinyl acetate monomer and 30 to 60 weight percent of an acrylate monomer in the action of reaction solvent and an evocating agent which accounts for 0.4 to 0.9 weight percent of the total weight of the monomers through free radicals; and the functional polymer is one or more of rosin, modified rosin, polyterpene, modified terpene, aliphatic petroleum resin and aromatic petroleum resin. When used in ink, the ester-soluble resin not only makes the ink environmentally-friendly, and but also endows the ink with the advantages of high paint adaptability, high printing adaptability and the like.

Owner:戎昌栋 +3

Anti-scraping corrosion-resistant ink and preparation method thereof

The invention provides anti-scraping corrosion-resistant ink which comprises, by weight parts, 55-68 parts of polyurethane modified epoxy-acrylate resin, 14-21 parts of gum dammar, 7-12 parts of polyterpene phenolic resin, 3-8 parts of butyl methacrylate, 4-9 parts of calcium lignosulfonate, 3-7 parts of nano silica, 1.8-3.4 parts of mica iron oxide, 3-6 parts of short carbon fiber, 2-5 parts of difenoconazole, 1-3.2 parts of coupling agent, 1.5-2.7 parts of flatting agent and 125-150 parts of solvent. After being dried, the prepared anti-scraping corrosion-resistant ink is high in hardness and adhesion and resistant to scraping. The anti-scraping corrosion-resistant ink is excellent in acid and alkali corrosion resistance testing performance, can meet the application requirements in the severe environment and is good in market prospect.

Owner:苏州市奎克力电子科技有限公司

Cross-linked rubber adhesive, high-bonding-strength shock absorbing and silencing tape applying rubber adhesive and preparation method of rubber adhesive and tape

ActiveCN109796880AHigh bonding strengthWaterproofNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCross-linkPolymer science

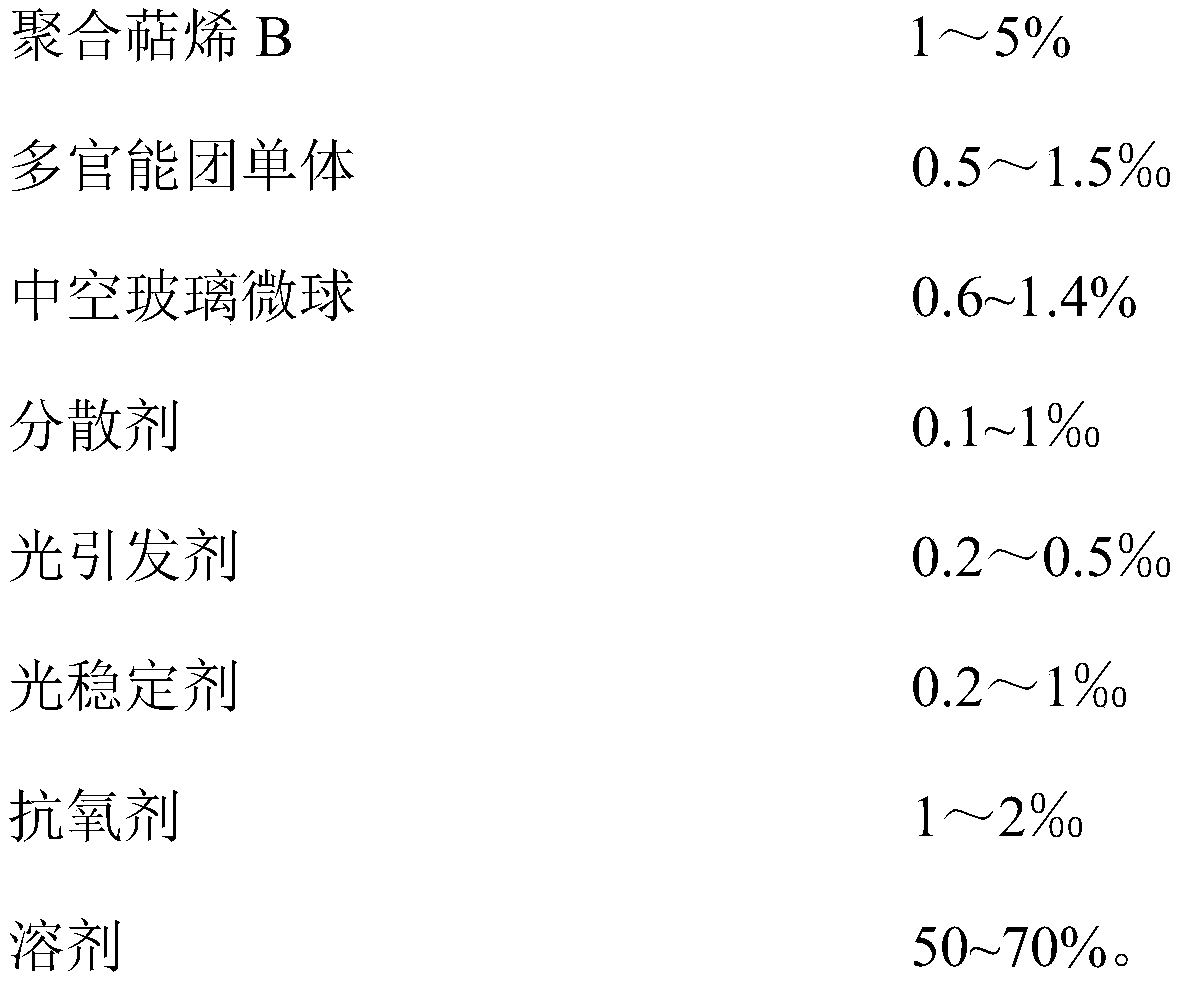

The invention discloses a cross-linked rubber adhesive. The cross-linked rubber adhesive is prepared from, by mass, 12-18% of star type SIS, 12-18% of polyterpene A, 1-5% of polyterpene B, 0.05-0.15%of a polyfunctional group monomer, 0.6-1.4% of hollow glass microspheres, 0.01-0.1% of a dispersing agent, 0.02-0.05% of a photoinitiator, 0.02-0.1% of a light stabilizer, 0.1-0.2% of an antioxidant and 50-70% of a solvent. The cross-linked rubber adhesive and high-bonding-strength shock absorbing and silencing tape applying the rubber adhesive have the advantages of water prevention, shock absorption, sound attenuation, high bonding strength, excellent aging performance and good subsequent die cutting processing performance, and can be used as double-sided adhesive tape in the fields of someautomobiles and electronics well.

Owner:新纶电子材料(常州)有限公司

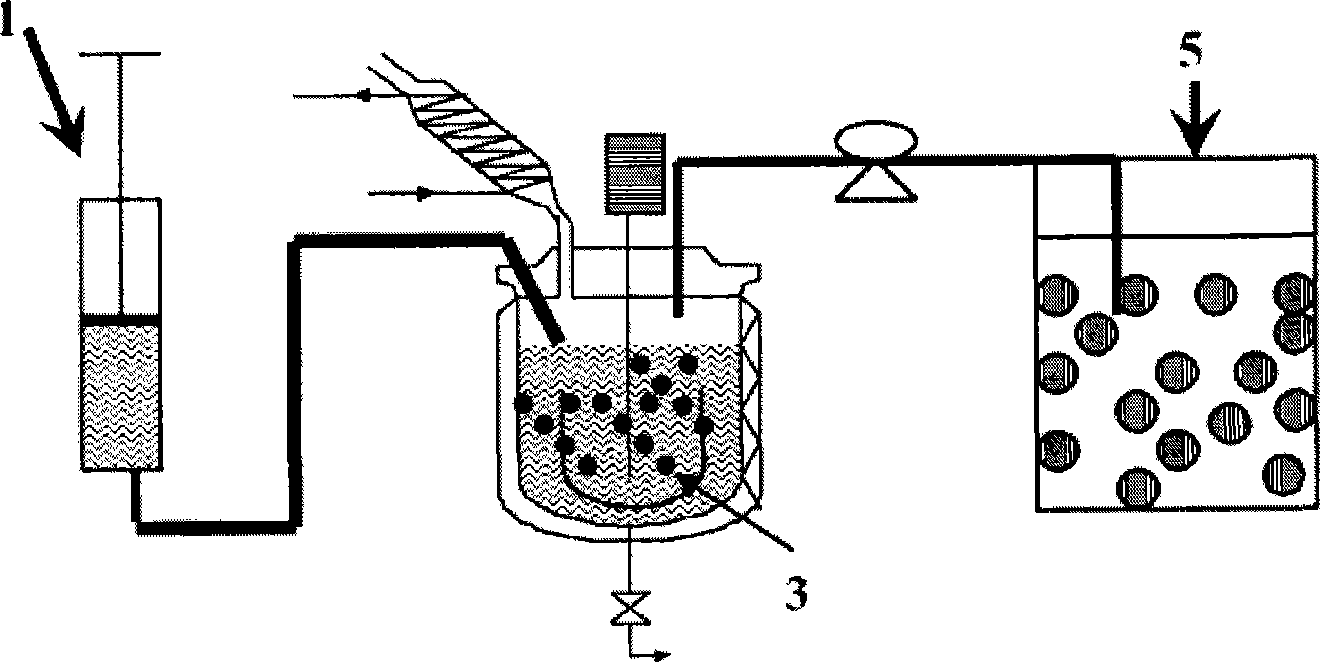

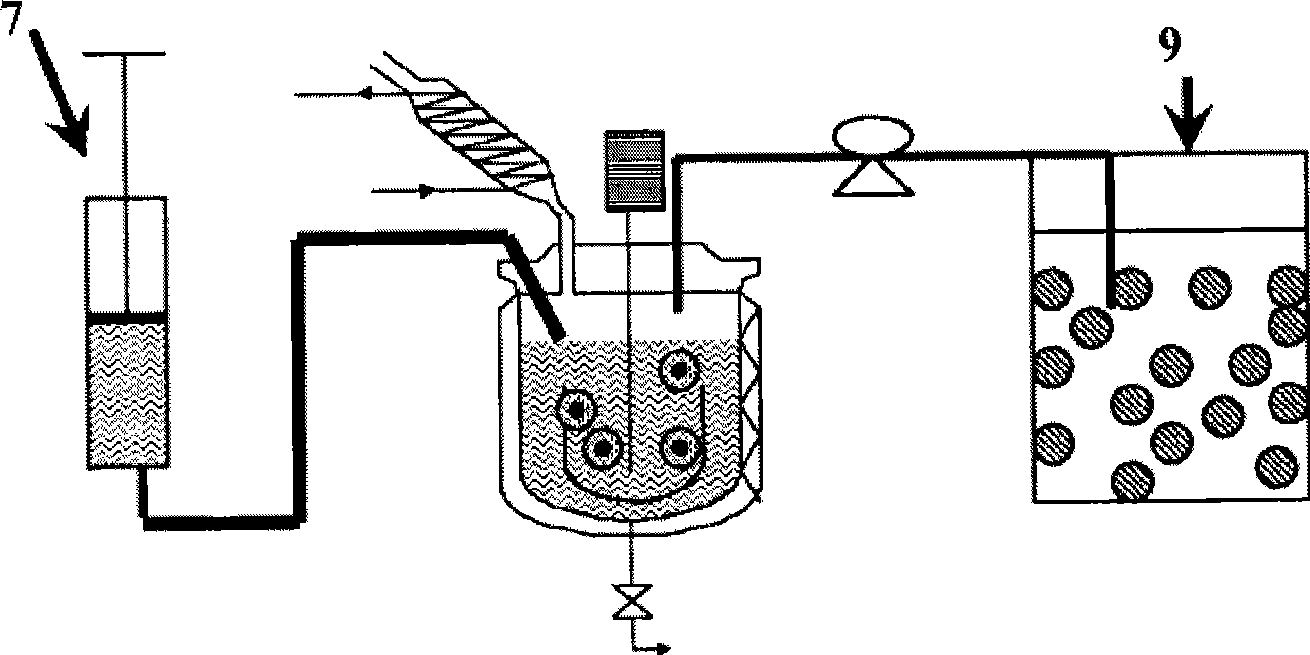

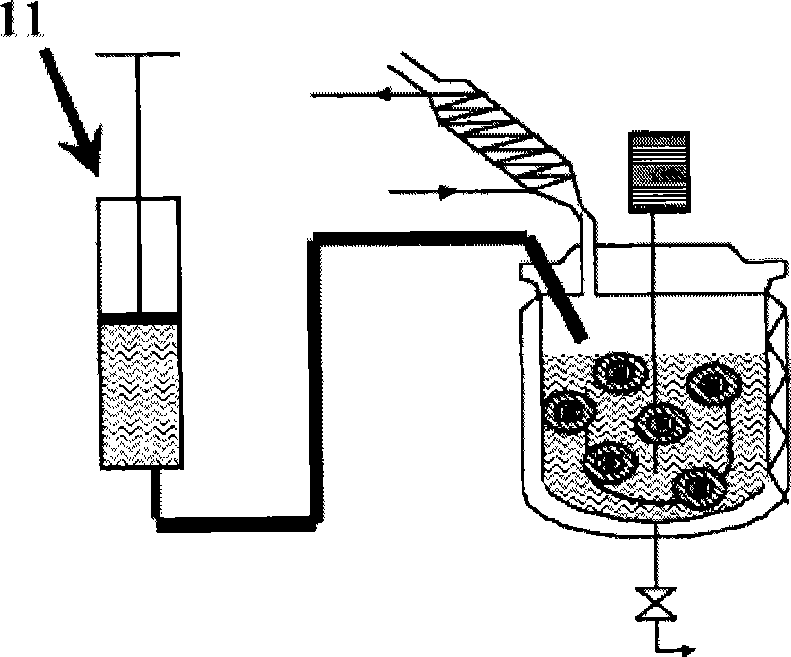

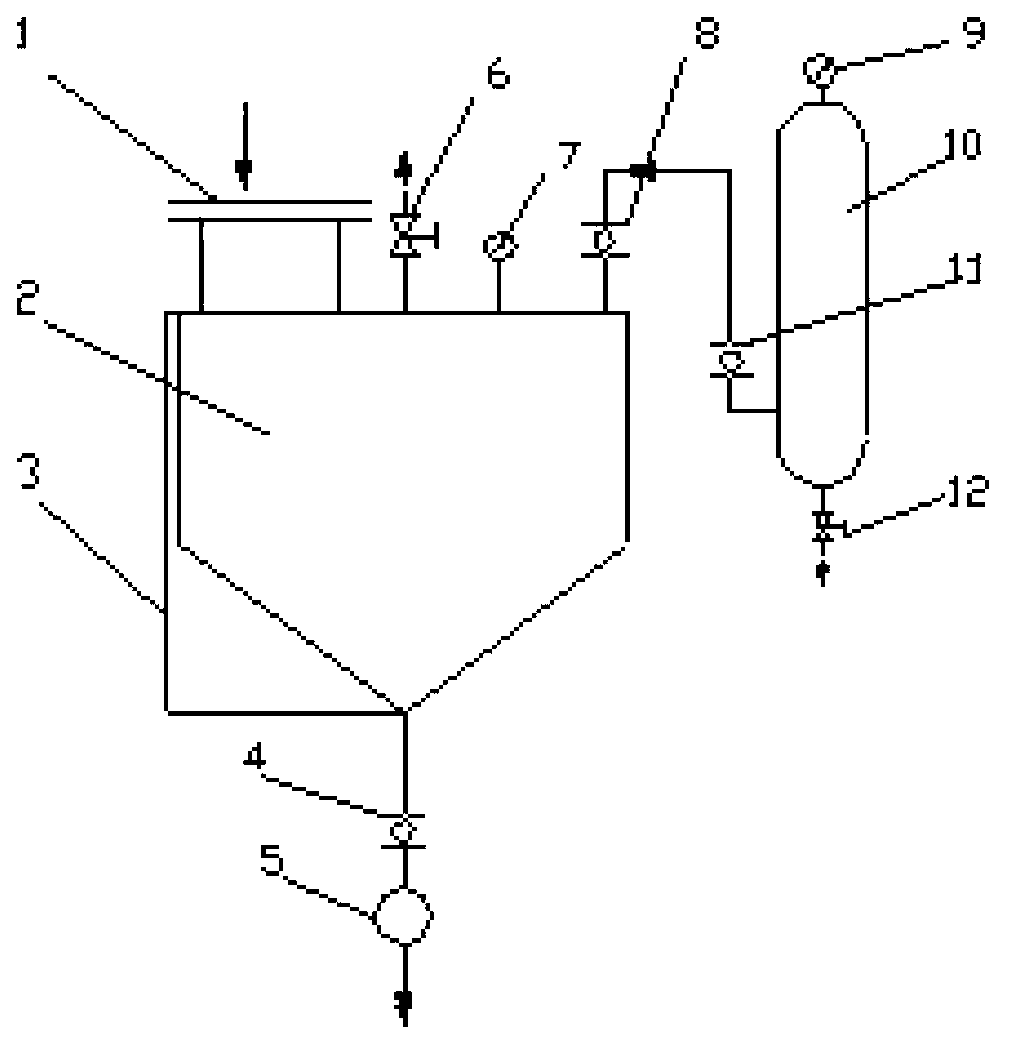

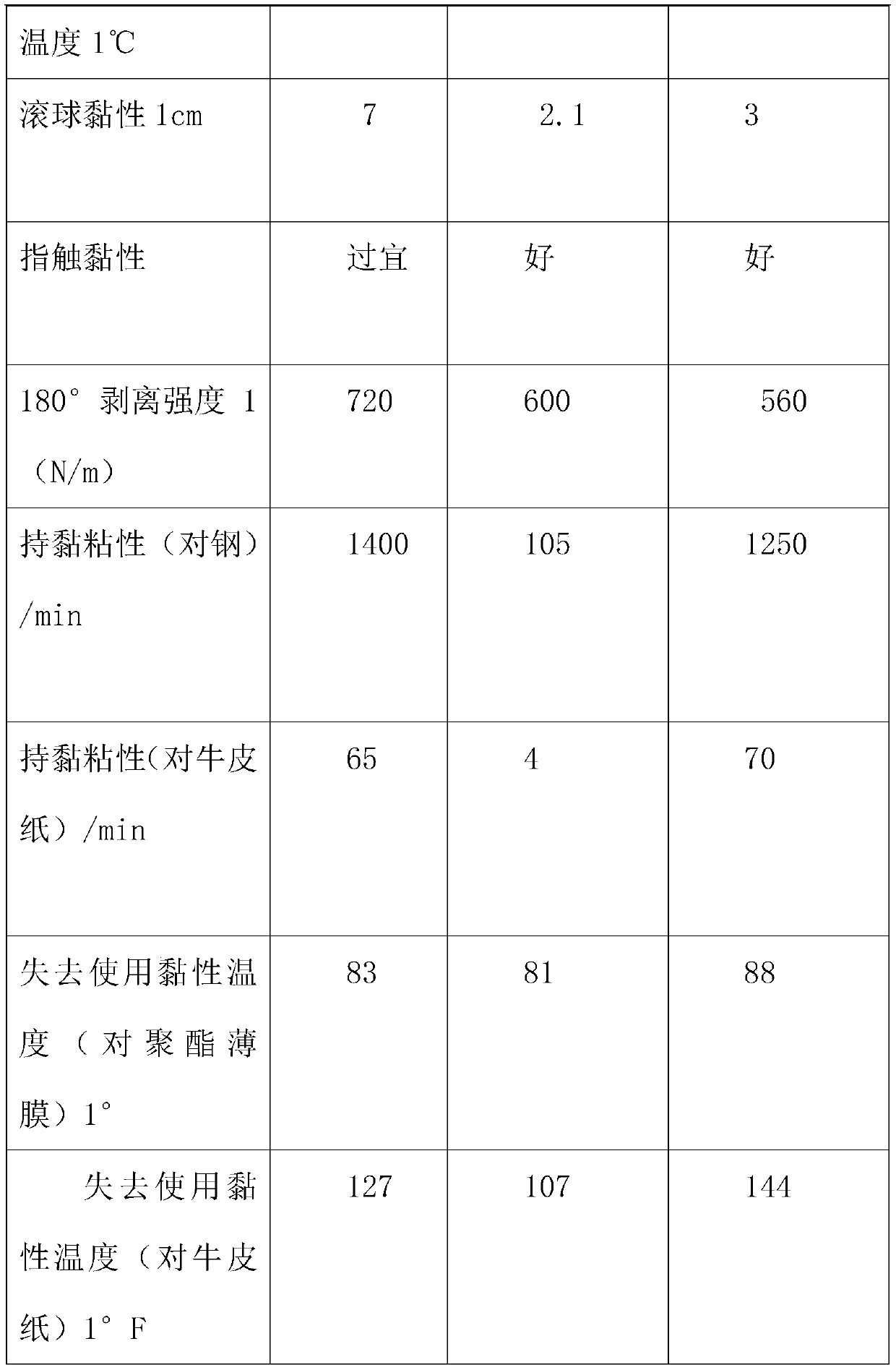

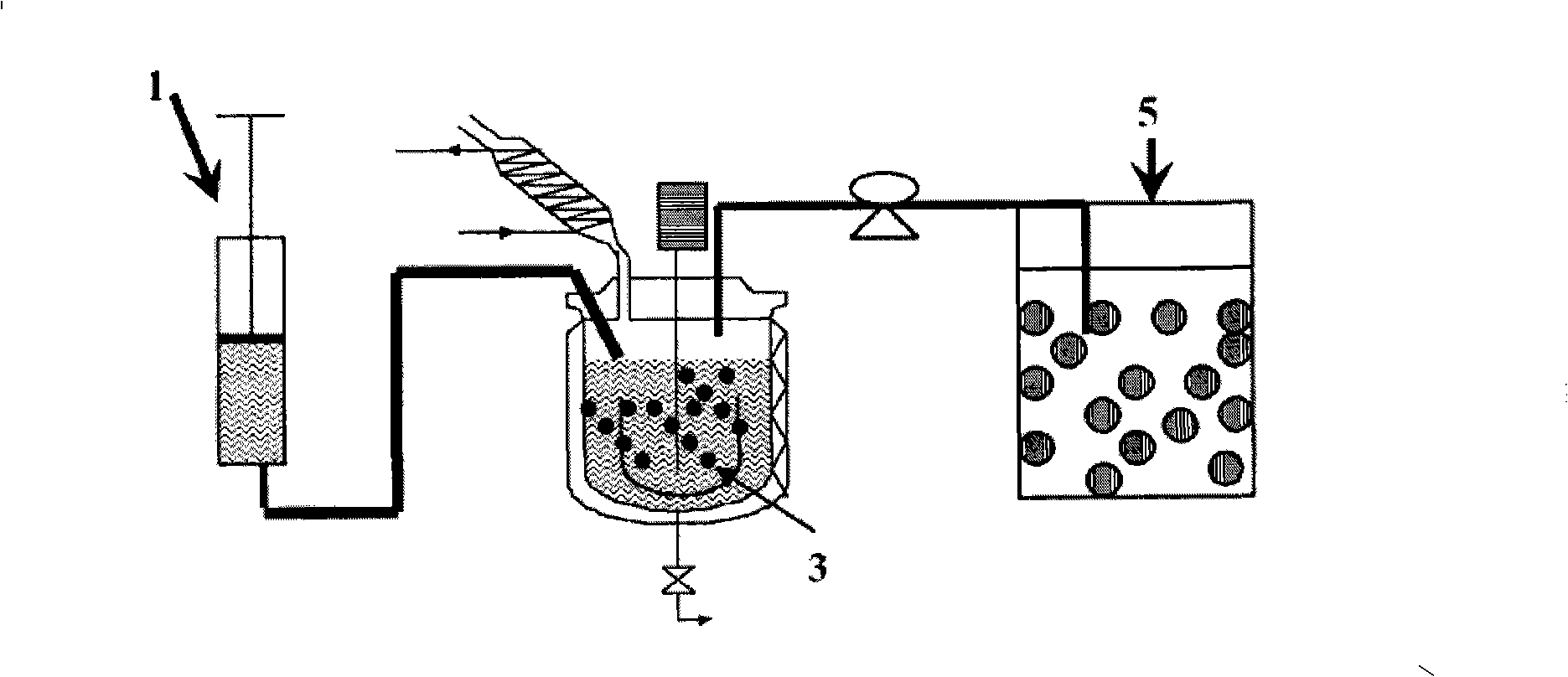

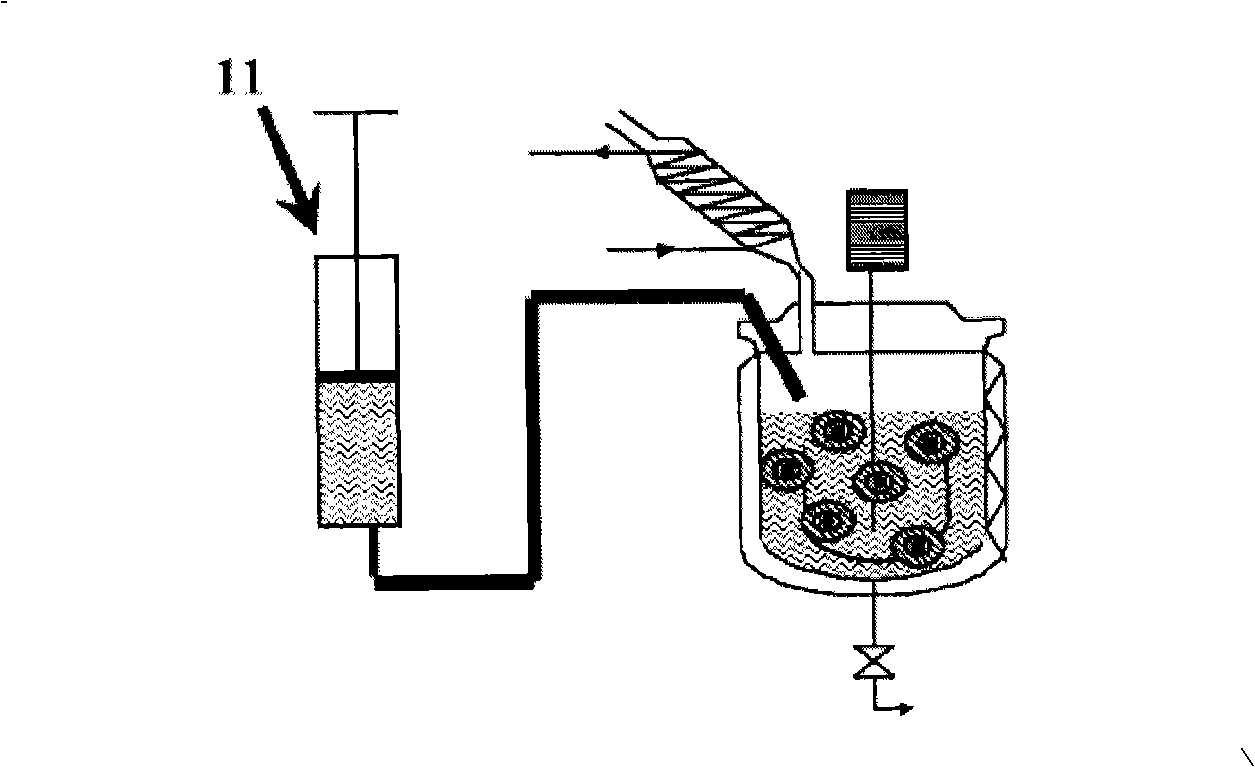

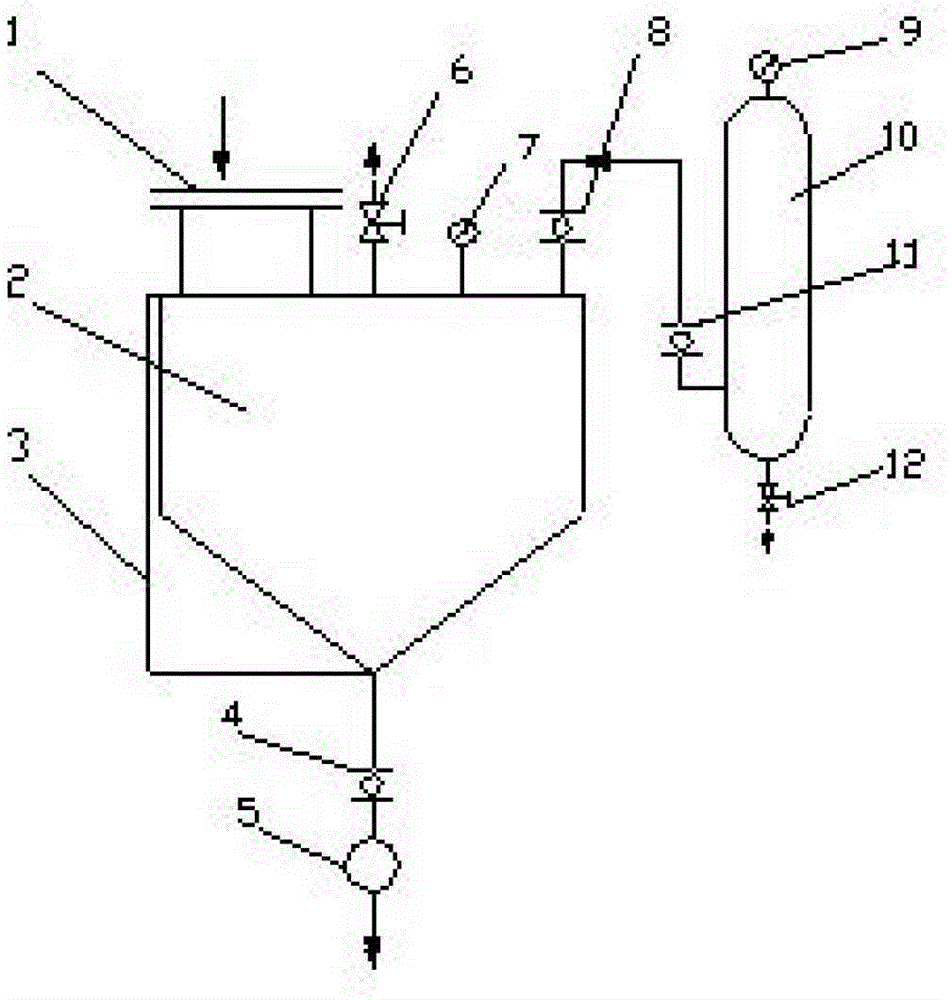

Method and special device for adding catalyst in polymerization reaction for producing polyterpene resin

The invention relates to a method and special device for adding a catalyst in polymerization reaction for producing polyterpene resin. The method is characterized by comprising the following steps of: 1) well preparing the special device for adding the catalyst, firstly closing a discharge butterfly valve, adding the catalyst (aluminum trichloride) required for one reaction process in the polymerization reaction for producing the polyterpene resin into a feed tank of the device for adding the catalyst once, and tightly covering a catalyst feed port of the feed tank; 2) filling nitrogen into the feed tank till the gas pressure in the feed tank achieves 0.05Mpa; and 3) adding turpentine oil into a reaction kettle, then slowly opening the catalyst discharge butterfly valve, and regulating the size of the valve to control the flow rate to achieve 10kg / 20-25min. According to the method disclosed by the invention, the connection from the catalyst feed port of the feed tank to the reaction kettle constitutes a fully closed reaction system, the catalyst which is added in the polymerization reaction is input once and automatically conveyed in a closed device, and the method has the beneficial effects of slow and uniform adding speed, mild material reaction and capability of ensuring safety of the device and safety in operation of staff.

Owner:广东星光脂胶科技股份有限公司

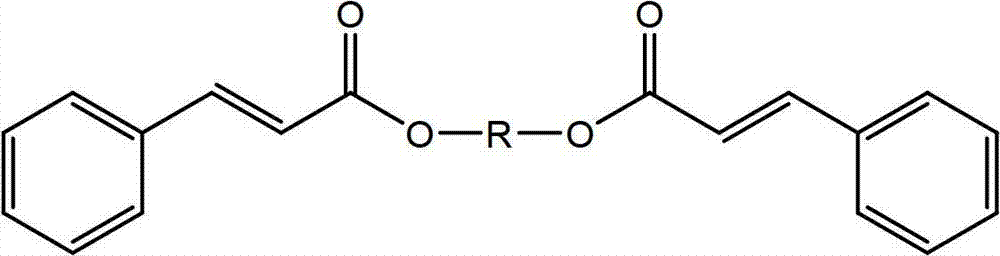

Phase change inks containing crystalline trans-cinnamic diesters and polyterpene resins

Disclosed is a phase change ink comprising an ink carrier which comprises: (a) a crystalline trans-cinnamic diester; and (b) an amorphous polyterpene resin.

Owner:XEROX CORP

Transparent heat-insulating polystyrene composite material

InactiveCN106751081AImprove insulation effectImprove flame retardant performancePolyvinyl butyralCellulose

The invention discloses a transparent heat-insulating polystyrene composite material. The transparent heat-insulating polystyrene composite material comprises the following raw materials in parts by weight: 70 to 100 parts of polystyrene, 10 to 30 parts of polyterpene phenolic resin, 3 to 7 parts of K resin, 5 to 10 parts of polyvinyl butyral, 1 to 5 parts of tert-butyl peroxybenzoate, 1 to 3 parts of resorcinol bis(diphenyl phosphate), 5 to 10 parts of hydroxy propyl distarch phosphate, 1 to 3 parts of hydroxyl silicone oil, 0.5 to 2 parts of sodium polyacrylate, 100 to 200 parts of heat-insulating filler, 0.5 to 1.5 parts of an antioxidant and 0.5 to 1.5 parts of a light stabilizer; the heat-insulating filler comprises modified transparent powder, hollow nano-silicon dioxide microspheres and polyanionic cellulose which are in the mass ratio of 2-4:1-2:1. Through a plurality of experiments, the transparent heat-insulating polystyrene composite material has good heat insulating performance, simultaneously can maintain good fire resistance, transparency and corrosion resistance, and is convenient to process and plasticize; the application range of the heat-insulating material is further enlarged.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

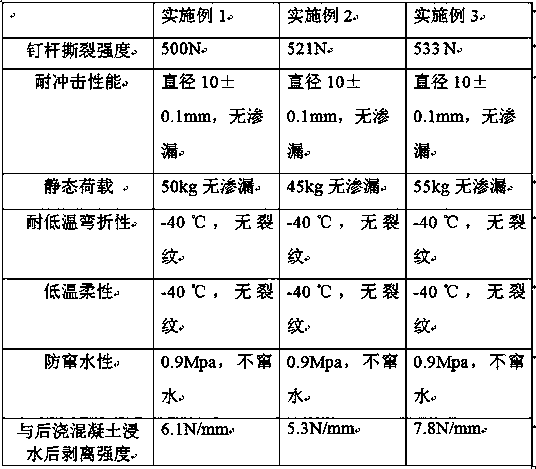

Pre-laying self-adhesion polymer modified bituminous waterproof sheet material and preparation method thereof

InactiveCN110106715AGood self-adhesive effectStrong anti-channelingTextiles and paperPolymer modifiedBituminous waterproofing

The invention provides a pre-laying self-adhesion polymer modified bituminous waterproof sheet material. The waterproof sheet material comprises a modified bitumen layer, and the modified bitumen layer is prepared from, by weight, 75-80 parts of bitumen 130, 50-55 parts of bitumen 90, 8-9 parts of wax oil, 7-8 parts of propyl p-hydroxybenzoate, 11-14 parts of coumarone resin, 9-12 parts of SBR, 5-5.8 parts of EVA, 7-9 parts of coal tar, 7-8 parts of xanthan gum, 12-15 parts of dicyclopentadiene petroleum resin, 15-17 parts of polyterpene phenolic resin, 2-2.5 parts of sorbitol, 4-5 parts of ananti-oxidant and 4-5 parts of a thickening agent. The bituminous waterproof sheet material is used for underground waterproof engineering in a cold region, the pre-laying self-adhesion effect is goodin a low-temperature environment, after the bituminous waterproof sheet material and post-cast concrete are immersed into water, the peeling strength is high, the static load capacity is high, and the water channeling resistance is high.

Owner:富华防水科技股份有限公司

Temperature-resistant hot melt adhesive for military electronic components and preparation method thereof

InactiveCN108676523AGood high and low temperature resistanceImprove performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesLinear low-density polyethyleneAntioxidant

The invention discloses temperature-resistant hot melt adhesive for military electronic components and a preparation method thereof. The temperature-resistant hot melt adhesive comprises the followingraw materials (by weight): 30-45 parts of EVA resin, 18-26 parts of thermosetting liquid polyimide pure resin, 16-25 parts of polyterpene phenolic resin, 5-8 parts of polyethylene wax, 2-4 parts of isobutyl triethoxysilane, 3-5 parts of expandable graphite, 2-4 parts of linear low density polyethylene, 2.5-4.5 parts of an adhesive modifier, 0.8-1.3 parts of an antioxidant, and 1-1.5 parts of a heat stabilizer. The formula of the temperature-resistant hot melt adhesive for military electronic components is reasonable. After prepared, the temperature-resistant hot melt adhesive for military electronic components has good high-and-low temperature resistance, adhesive property, thermal stability, mechanical properties and the like, has excellent comprehensive performance, can be used in the preparation of parts or equipment in the industries of aerospace, ships and warships, radar, electronic information equipment and the like, and has good effects.

Owner:ANHUI NIKOLA ELECTRONICS TECH CO LTD

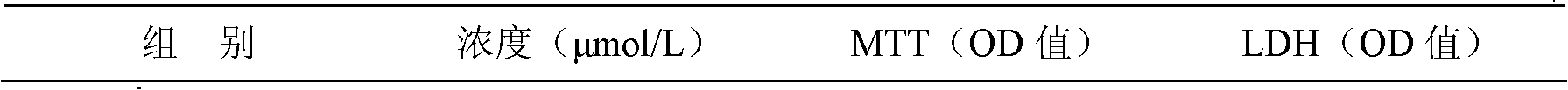

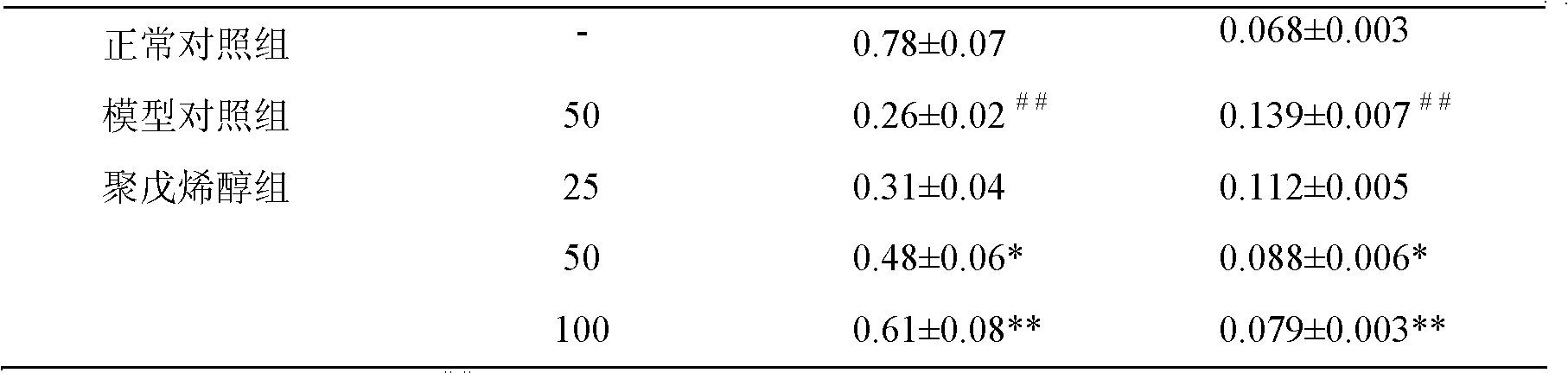

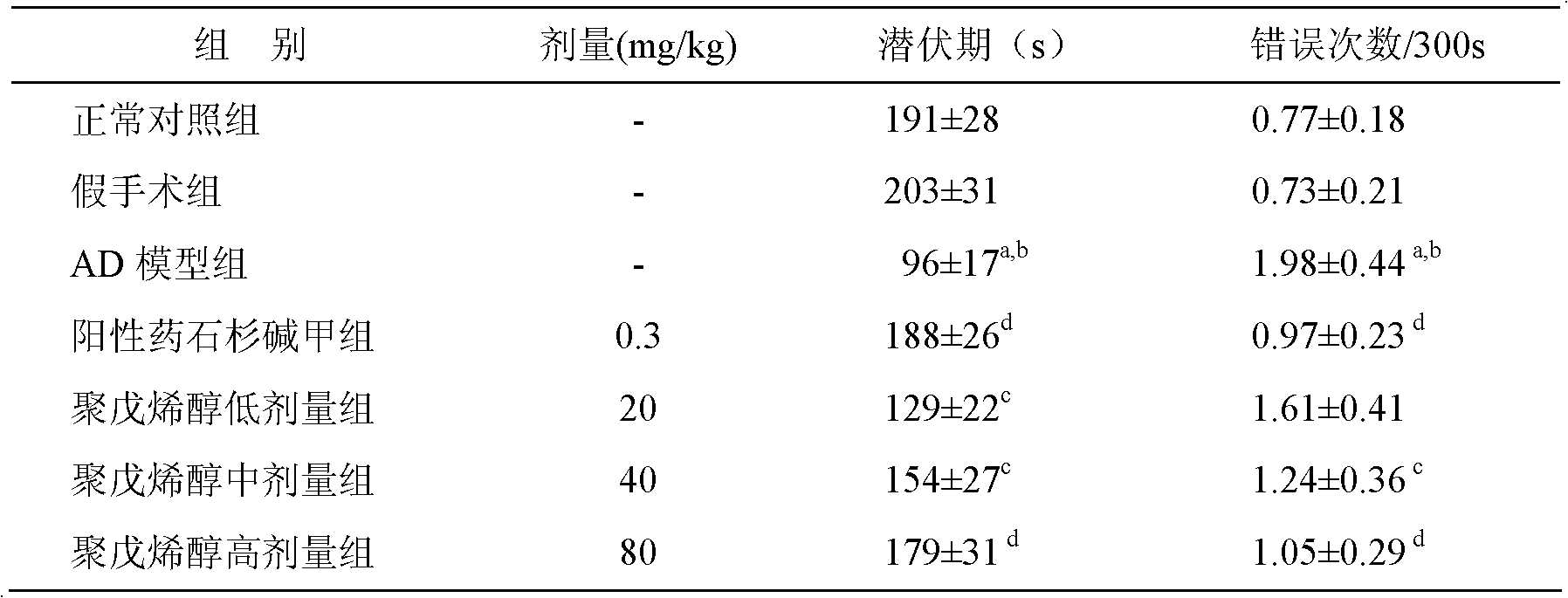

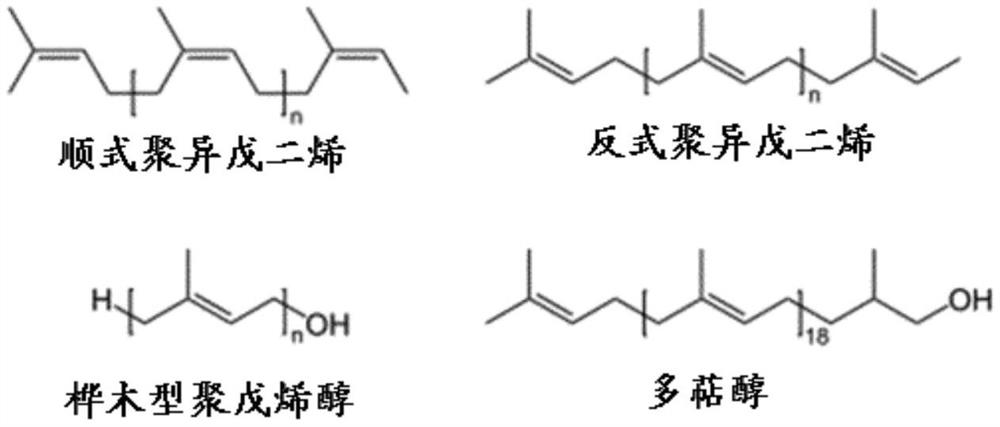

Application of needle-leaved polyprenol in preparing medicines for preventing and treating Alzheimer disease

InactiveCN102028674AHas a preventive effectNo side effectsNervous disorderHydroxy compound active ingredientsPheochromocytomaLarch

The invention belongs to the technical field of medicines, and discloses an application of needle-leaved polyprenol in preparing medicines for preventing and treating Alzheimer disease. The needle-leaved polyprenol is obtained from needle leaves of pinaceae plants such as pinus, picea, larch, fir and cedar and the like by extraction, separation and purification. The needle-leaved polyprenol is long-chain polyterpene compound formed by 14-24 isopentene group units. Cell and animal experimental results indicates that the needle-leaved polyprenol has functions of preventing and treating the Alzheimer disease, i.e., the needle-leaved polyprenol has a protection function for damage of pheochromocytoma (PC) 12 nerve cells caused by amyloid-beta protein, and can improve the passive avoidance memory capability and space learning memory capability of demented mice. Therefore, the needle-leaved polyprenol can be used for preparing the medicines for preventing and treating the Alzheimer disease.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Radiology tumor imaging agent and preparation method thereof

InactiveCN107569694AHigh softening pointClear imagingNMR/MRI constrast preparationsSide effectAdditive ingredient

The invention discloses a radiology tumor imaging agent and a preparation method thereof, and belongs to the technical field of imaging agents. The radiology tumor imaging agent is prepared from the following raw materials: beta-polyterpene resin, polyvinyl alcohol, hollow spherical hydroxyapatite, nanometer gadolinium oxalate, titanium dioxide, radix et caulis opuntiae dillenii, rhei radix et rhizoma, roasted galli gigerii endothelium corneum, rehmanniae radix praeparata, scutellariae barbatae herba, pericarpium citri reticulatae and radix et rhizoma glycyrrhizae. According to the radiology tumor imaging agent and the preparation method thereof, four raw materials, i.e. the beta-polyterpene resin, the hollow spherical hydroxyapatite, the nanometer gadolinium oxalate and the titanium dioxide, are used as basic materials, and are mutually complemented by Chinese herbal ingredients used as auxiliaries to increase the cure rate of tumors and prevent a human body from extra damage caused by radiation. The tumor imaging agent has a certain therapeutic effect on the tumors, the tumor volume reduction rate is 82 to 85 percent, the radiation protection rate is 92.6 to 94.8 percent, pains and side effects are avoided, a relatively good therapeutic effect is achieved, and the symptoms are obviously improved after 40 to 45 days.

Owner:杨润

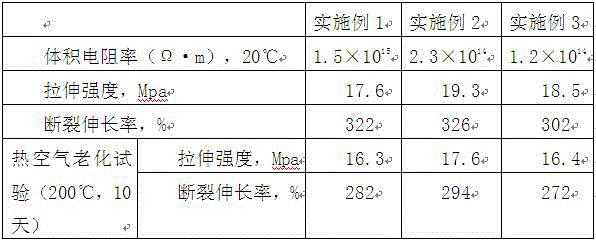

Modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and preparation method thereof

InactiveCN106589494AHigh volume resistivityGood compatibilityRubber insulatorsRubber materialPolymer science

The invention discloses a modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and a preparation method thereof. The modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material is prepared from the following raw materials in parts by weight: 50 to 60 parts of acrylonitrile rubber, 30 to 35 parts of pseudo-boehmite, 20 to 30 parts of thermoplastic polyurethane elastomer, 30 to 40 parts of poly(isobutylene-co-p-methyl-styrene-co-p-bromomethylstyrene), 10 to 12 parts of neopentyl glycol dibenzoate, 6 to 8 parts of calcium stearate, 30 to 40 parts of 2-ethylhexyl diphenyl phosphate, 3 to 5 parts of zinc oxide, 6 to 8 parts of chloropropyl triethoxy silane, 4 to 6 parts of polyterpene phenolic resin, and the like. According to the modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and the preparation method thereof provided by the invention, the modified pseudo-boehmite butadiene-acrylonitrile rubber is used, so that the volume resistivity of the acrylonitrile rubber is increased, and an electrical insulation property of the acrylonitrile rubber is improved; and the pseudo-boehmite treated by the chloropropyl triethoxy silane, the epoxidized methyl acetorieinoleate and the 2-ethylhexyl diphenyl phosphate is used as a filler, so that a mechanical property of the product is improved, the surface states of pseudo-boehmite particles can be well improved, the compatibility of the pseudo-boehmite particles and the acrylonitrile rubber is improved, and the ageing resistance of the acrylonitrile rubber material can be remarkably improved.

Owner:盛天洋

Special medicinal rhubarb organic fertilizer and manufacturing method thereof

InactiveCN109456124APromote growthImprove water retentionCalcareous fertilisersBio-organic fraction processingDiseaseGuano

The invention discloses a special medicinal rhubarb organic fertilizer and a manufacturing method thereof, and belongs to the technical field of fertilizers. The organic fertilizer is prepared from, by weight, 30-40 parts of cow dung, 5-10 parts of bamboo charcoal, 2-5 parts of fulvic acid, 1-3 parts of nicotinic acid amide, 20-30 parts of chicken manure, 10-15 parts of chimney ash, 1-5 parts of attapulgite powder, 20-30 parts of bran, 20-25 parts of fish bone meal, 20-30 parts of salt, 10-15 parts of sodium carbonate, 20-25 parts of guano, 15-20 parts of sunflower straw ash, 5-7 parts of medical stone powder, 5-10 parts of carnallite, 3-7 parts of polyterpene bacillus agents, 5-8 parts of actinomycete agents, 5-7 parts of glauconite, 10-15 parts of seaweed, 5-10 parts of fatty acid, 3-10parts of dolomite, 1-3 parts of zeolite, 2-5 parts of oxalic acid and 5-8 parts of potassium salt. According to the organic fertilizer, stress resistance of medicinal rhubarb can be effectively improved, reproduction of harmful and pathogenic microorganisms in soil can be effectively restrained, the acre yield of the medicinal rhubarb can reach 742kg or more after the organic fertilizer is applied, and the incidence rate of root rot diseases of the medicinal rhubarb is lower than 27%.

Owner:陇南远大生物科技有限公司

Oxygen Barrier Plastic Material

PendingUS20190210337A1High oxygen permeabilitySynthetic resin layered productsDomestic containersPolymer sciencePolyethylene terephthalate glycol

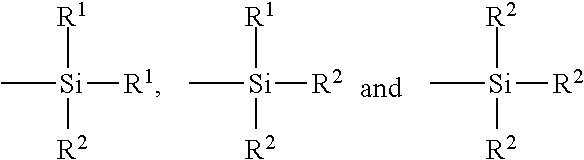

The invention relates to a multilayer packaging film comprising at least three different types of layers (A), (B), and (C): (A) is at least one outer layer, (B) is at least one passive oxygen barrier layer, (C) is at least one active oxygen scavenging layer, characterized in that —the at least one outer layer (A) is a thermoplastic polymer; —the at least one passive oxygen barrier layer (B) is selected from the group consisting of ethylene vinyl alcohol copolymers, polyvinylchloride, copolymers of polyvinyl chloride, polyvinyl alcohol, polyvinylidene dichloride, copolymers of polyvinylidene dichloride, polyacrylonitrils, copolymers of polyacrylonitrils, polyethylene terephthalate, polyethylene naphthalate, polyethylenefuranoate, polysiloxanes, and polyamides; —the at least one active oxygen scavenging layer (C) comprises a) a plastic material which is a polyolefin, a polyolefin copolymer or a polystyrene, and additives (b) and (c), wherein b) is a polyterpenic resin; and c) is a transition metal catalyst

Owner:CLARIANT PLASTICS & COATINGS LTD

Medical chewing gum

ActiveUS20170020812A1Good reproducibilityOrganic active ingredientsNervous disorderPolyvinyl acetatePolymer science

The invention relates to a medical chewing gum comprising gum base polymers and an active pharmaceutical ingredient, the gum base polymers comprising polyvinyl acetate and vinyl laurate-vinyl acetate copolymer in an amount of more than 90% by weight, wherein the gum base polymers include 20-95% by weight of polyvinyl acetate and -80% by weight of vinyl laurate-vinyl acetate copolymer, and wherein the chewing gum contains no polyterpene resins and no resins based on gum rosin, wood rosin or tall oil resin.

Owner:FERTIN PHARMA AS

Repair adhesive for tires and preparation method of repair adhesive

InactiveCN109280517AEffective protectionWear-resistantMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesAntioxidantAdhesive

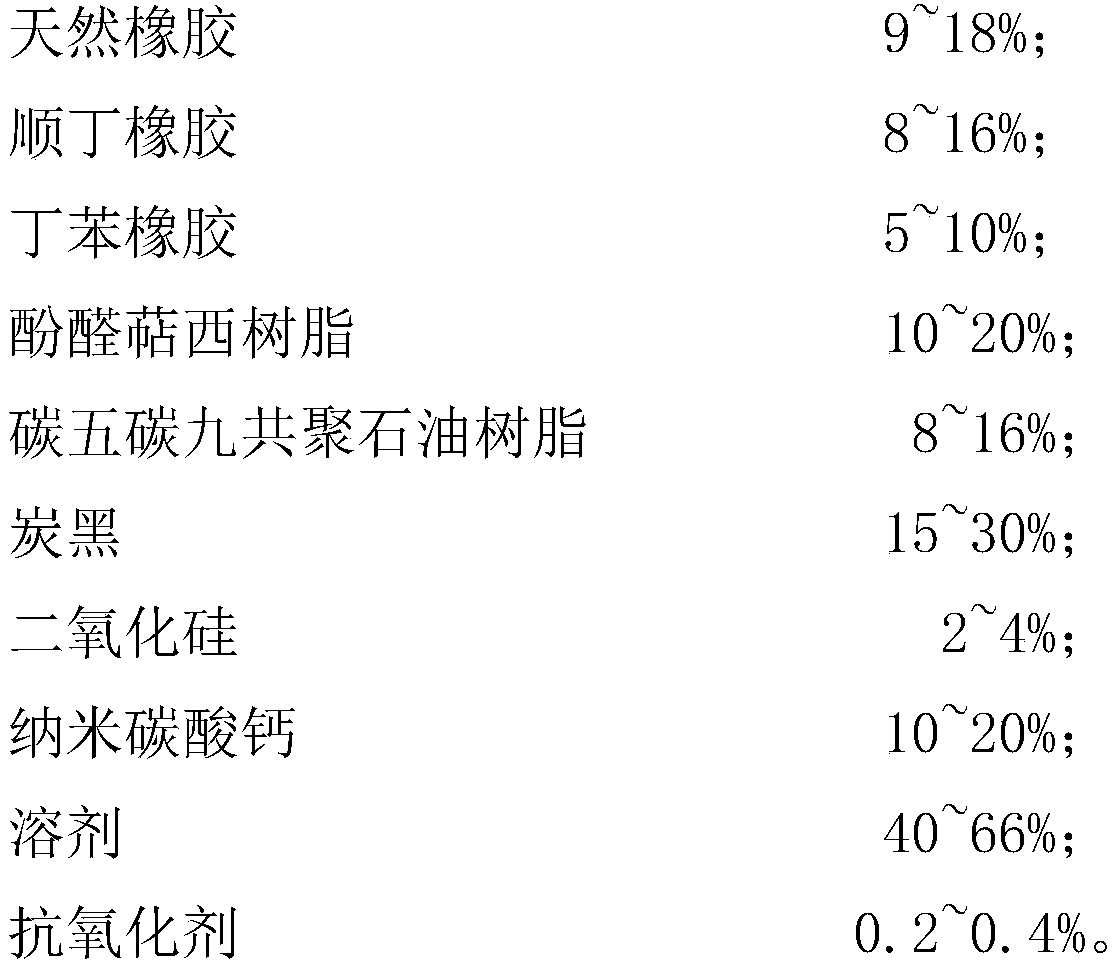

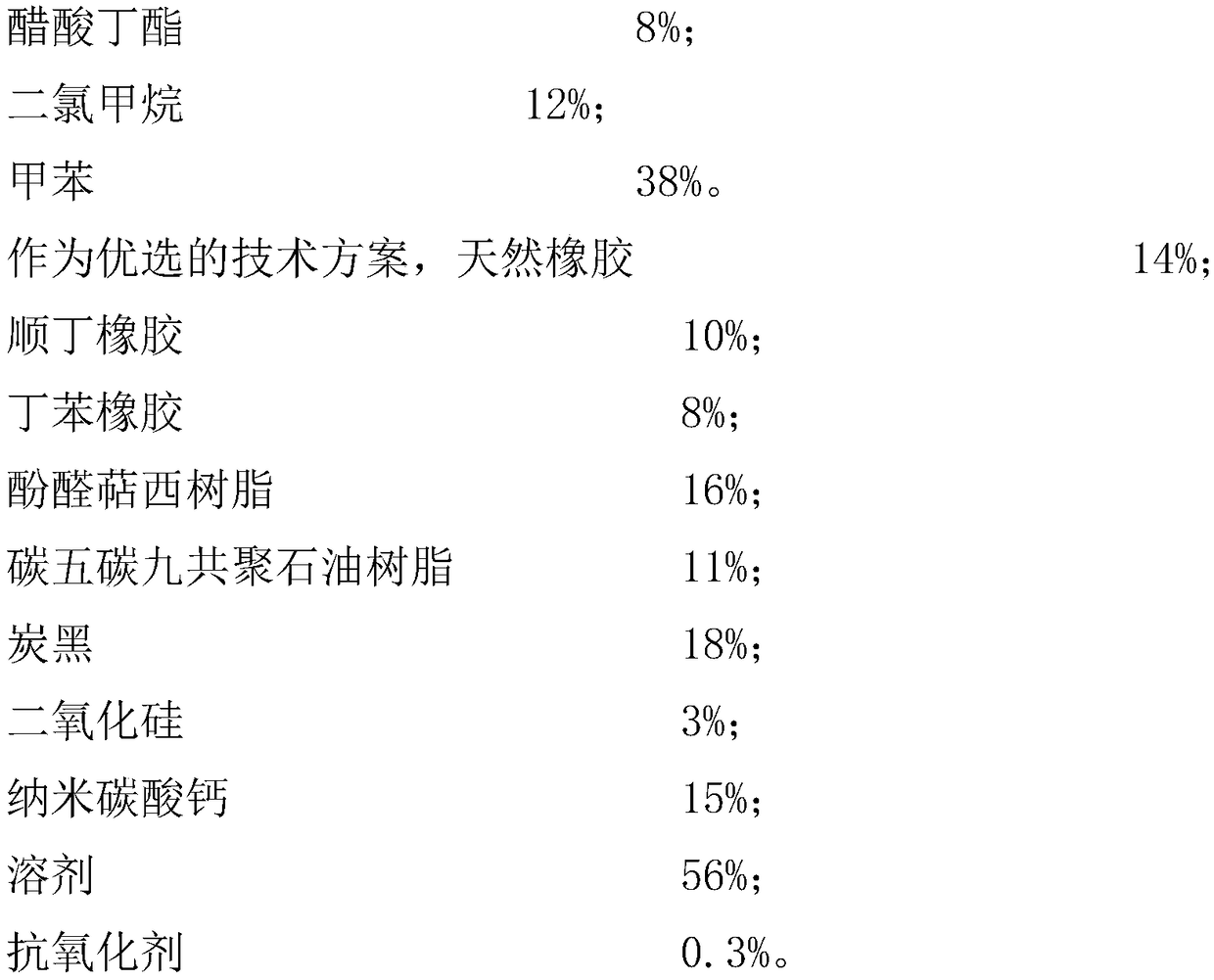

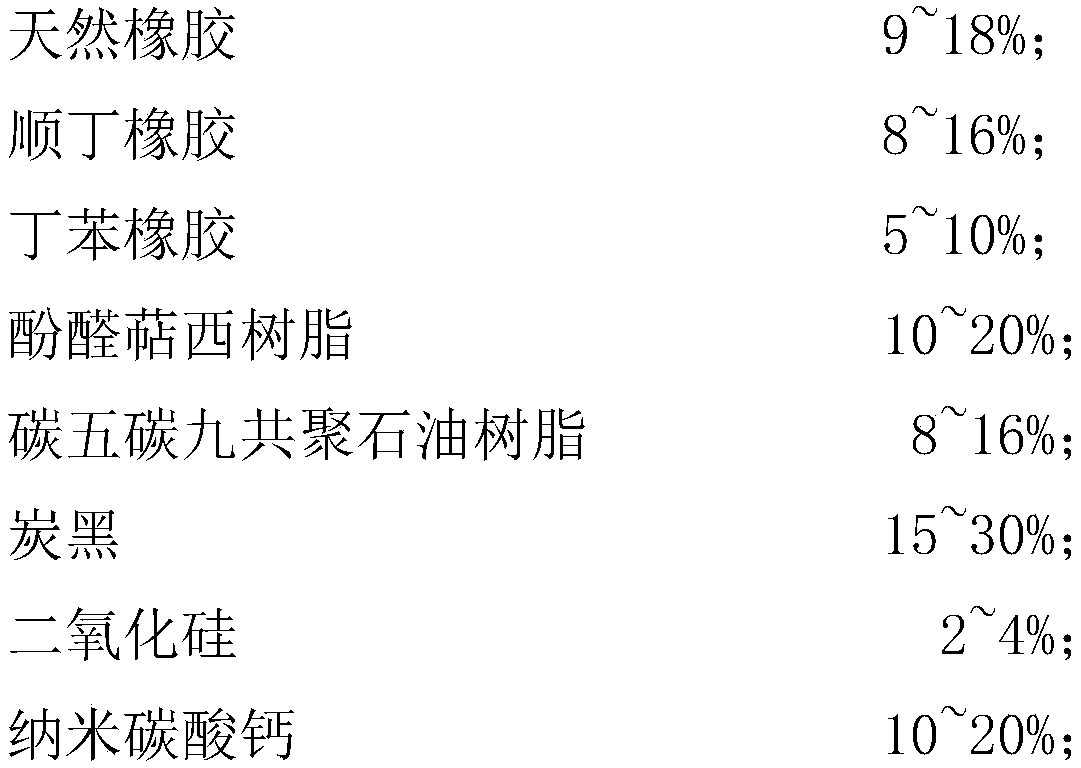

The invention discloses a repair adhesive for tires and a preparation method of the repair adhesive. The repair adhesive is prepared from the following raw materials in parts by weight: 9-18% of natural rubber, 8-16% of cis-butadiene rubber, 5-10% of styrene-butadiene rubber, 10-20% of polyterpene phenolic resin, 8-16% of C5-C9 copolymerized petroleum resin, 15-30% of carbon black, 2-4% of silicondioxide, 10-20% of nano calcium carbonate, 40%-66% of a solvent and 0.2%-0.4% of an antioxidant. The repair adhesive provided by the invention has the excellent characteristics of good bonding strength, fast drying, high solid content, wear resistance, high-temperature resistance, cold resistance, water resistance, acid and alkali resistance and the like, is used for repairing cracks, scratches and holes in tire surfaces and tire surface damages, can effectively protect tires, and can also repair air leakage from tack holes of the tires.

Owner:QUZHOU DONGKAI GLUE IND CO LTD

Anti-puncturing self-repairing tire upgrade rubber material

InactiveCN110283559AImprove adhesionImprove repair effectOther rubber adhesivesRubber materialPolymer science

The invention discloses an anti-puncturing self-repairing tire upgrade rubber material, and specifically relates to the technical field of preparation of rubber materials. The rubber material is prepared from the following raw materials in parts by weight: 95-105 parts of linear thermophilic rubber, 90-125 parts of hydrogenated polyterpene resin, and 20-50 parts of a butylene polymer. The rubber material has strong bonding capacity and can repair a tire automatically, and the repairing effect is relatively good.

Owner:辽宁神州风火轮轮胎科技有限公司

Moisture curable polyurethane adhesive and preparation method thereof

InactiveCN102108279AAffect application effectTechnical Defects Affecting ErgonomicsPolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

The invention relates to a moisture curable polyurethane adhesive and a preparation method thereof. The adhesive adopts polyether polyol, polyterpene phenolic resin and dibutyltin dilaurate for preparing a prepolymer; a cross-linking agent, a filler and color paste are added for preparing the polyurethane adhesive, the polyurethane adhesive comprises the following components in parts by weight: 66-68 parts of the polyether polyol (M is equal to 2800), 6.6-6.8 parts of the polyterpene phenolic resin, 0.12-0.14 part of stannous octoate, 0.66-0.68 part of the dibutyltin dilaurate, 3.0-3.6 parts of the cross-linking agent, 22.0-23.0 parts of the filler and an appropriate amount of the color paste, and the adhesive is obtained by reaction. After the adhesive is cured, the strength and the elongation rate of a body are higher, and the adhesive has high curing rate at low temperature. The adhesive is applicable to elastic adhesion under environments with high and low temperature, high and low humidity, high mechanical properties and the like, such as the adhesion of metal, wood, stone and the like, and is particularly applicable to toilets and kitchens for use.

Owner:GUANGXI NANNING QISHUN CHEM

Composition of special fluid and use

Composition of special fluid comprising at least one hydrogenated mono- and / or at least one polyterpene, in a mixture with at least one special fluid for industrial applications such as the petroleum industry, in construction as sealants and paints, adhesives, the inks industry, metal working, the treatment and protection of metals, but also for domestic uses and in the agric-food and plumbing industries.

Owner:TOTAL MARKETING SERVICES SA

Aqueous polymer dispersion and process

There is described a multi step process for preparing an aqueous dispersion of heterogeneous polymer particles by mini-emulsion polymerisation, the process comprising the steps of (I) (a) forming a mixture comprising: (i) water; (ii) at least one stabiliser (such as a surfactant and a hydrophobic co-stabliiser); (iii) at least one tackifier (such as polyterpenes, rosin resins and / or hydrocarbon resins); (iv) at least one ±,²-ethylenically unsaturated monomer;, (b) applying high shear to the mixture from step (a) to form an essentially stable mini-emulsion comprising an aqueous continuous phase and dispersed therein stabilised droplets of average diameter from about 10 to about 1000 nm, (c) polymerising the monomer(s) within the droplets in the presence of a free radical initiator; (d) adding further monomer to the dispersed phase to form a dispersion; then: (II) using the dispersion from step (I) as a seed to form a dispersion of heterogeneous polymer particles in a subsequent emulsion polymerisation. The resultant tackified PSAs may have a core shell structure and are stable under high shear.

Owner:CYTEC SURFACE SPECIALTIES INC

Bacteriostatic toothpaste containing seaweed enzyme and manufacture method thereof

InactiveCN109953910AEnhance humoral immunityInhibit productionAntibacterial agentsCosmetic preparationsDiseaseToothpaste

The present invention discloses a bacteriostatic toothpaste containing a seaweed enzyme and a manufacture method thereof. The bacteriostatic toothpaste comprises the following components in parts by weight: 40%-50% of a humectant, 10%-20% of a friction agent, 2%-3% of sodium lauroyl sarcosinate, 2%-4% of xanthan gum, 3%-5% of xylitol, 1%-2% of essence, 5%-7% of a seaweed enzyme, 3%-5% of a peony root bark extract and the balance water. The peony root bark extract is used at the same time to conduct sterilization of oral cavities and besides inhibits growth of bacteria in the oral cavities fora long time. Seaweed polysaccharide and polyterpene substances in the seaweed enzyme can effectively promote cellular immunity in the oral cavities, improve humoral immunity of the oral cavities and increase disease resistance of the oral cavities.

Owner:ZHEJIANG SHENYING TECH CO LTD

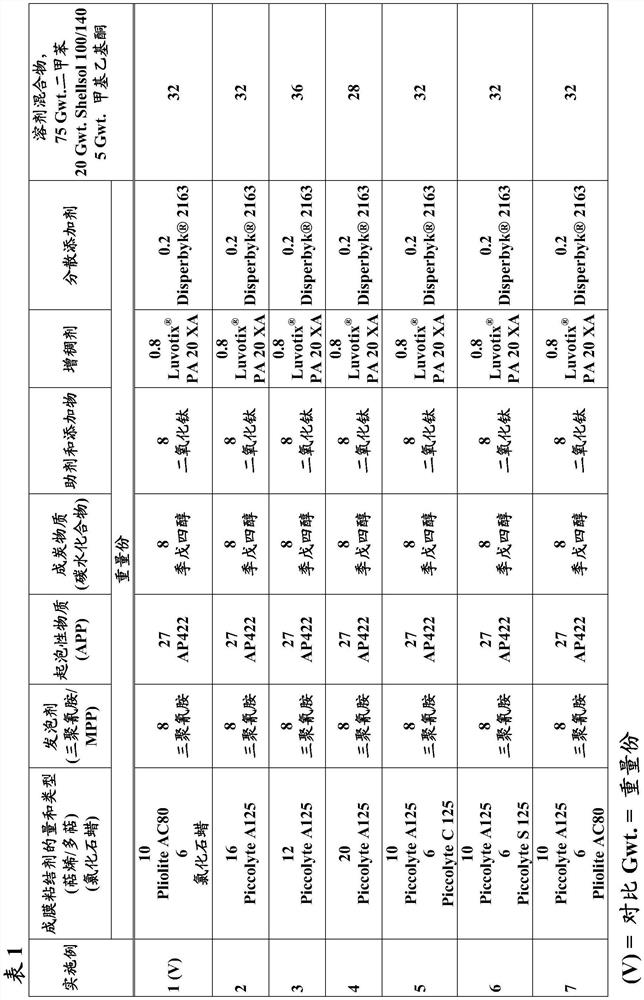

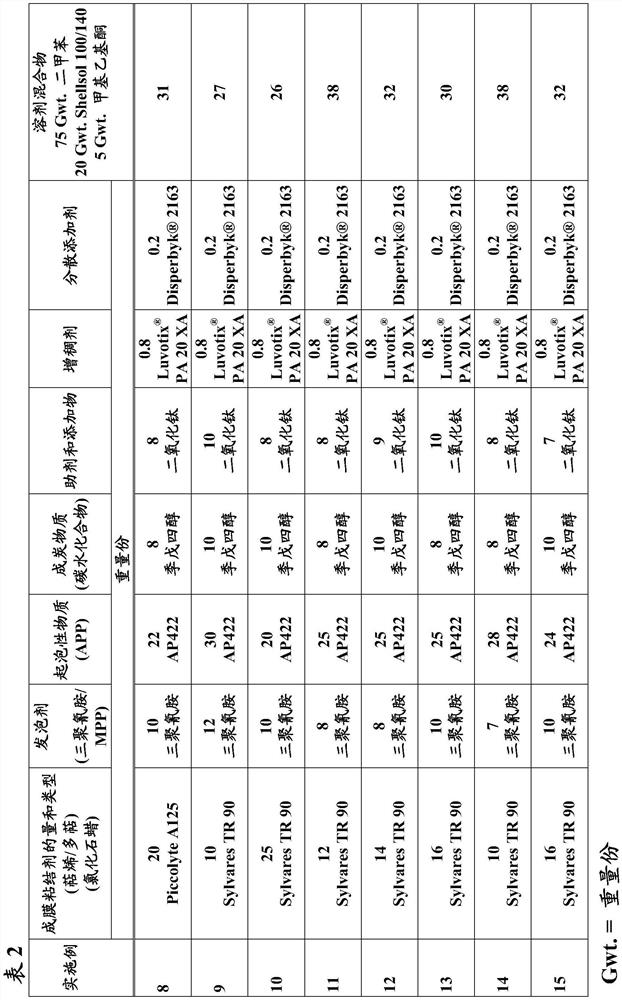

Halogen-free fire retardant coating capable of forming a barrier layer and use thereof

Owner:CLARIANT INT LTD

Method and special equipment for adding catalyst in polymerization reaction of terpene resin production

ActiveCN103288992BGuaranteed normal operationThe safety of the operator will be guaranteedButterfly valveNitrogen gas

The invention relates to a method and special device for adding a catalyst in polymerization reaction for producing polyterpene resin. The method is characterized by comprising the following steps of: 1) well preparing the special device for adding the catalyst, firstly closing a discharge butterfly valve, adding the catalyst (aluminum trichloride) required for one reaction process in the polymerization reaction for producing the polyterpene resin into a feed tank of the device for adding the catalyst once, and tightly covering a catalyst feed port of the feed tank; 2) filling nitrogen into the feed tank till the gas pressure in the feed tank achieves 0.05Mpa; and 3) adding turpentine oil into a reaction kettle, then slowly opening the catalyst discharge butterfly valve, and regulating the size of the valve to control the flow rate to achieve 10kg / 20-25min. According to the method disclosed by the invention, the connection from the catalyst feed port of the feed tank to the reaction kettle constitutes a fully closed reaction system, the catalyst which is added in the polymerization reaction is input once and automatically conveyed in a closed device, and the method has the beneficial effects of slow and uniform adding speed, mild material reaction and capability of ensuring safety of the device and safety in operation of staff.

Owner:广东星光脂胶科技股份有限公司

Non-toxic and harmless environment-friendly emulsifier

InactiveCN108641762ANon-toxic and no moisture phenomenonNo water separationLiquid carbonaceous fuelsAlkylphenolPhenol

The invention provides a non-toxic and harmless environment-friendly emulsifier. The non-toxic and harmless environment-friendly emulsifier is prepared from sorbitan fatty acid ester, alkylphenol ethoxylates, polyether, alkyl benzene sulfonic acid, polyterpene, N-(cyclohexylthio)phthalimide, phenol or benzene. The emulsifier is non-toxic and harmless to a human body, free of special smell, non-corrosive to equipment and safe to store and transport. Emulsified oil prepared from the emulsifier is stable in performance, long in shelf life and heat preservation period and low in consumption and cost, avoids demulsification and water-separation phenomena, realizes complete burning and eliminates black smoke and coking, and with the adoption of a concentrated emulsion technology and furnaces andkilns with thermal efficiency being about 40%, the fuel saving ratio can reach 10% or higher. The emulsifier can adapt to various emulsification processes and emulsification equipment.

Owner:NANTONG HAOLILAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com