Repair adhesive for tires and preparation method of repair adhesive

A technology for repairing rubber and tires, applied in the field of repairing rubber and its preparation, can solve the problems of sticking rubber, waste of resources, time-consuming, etc., and achieve the effects of good bonding strength, protection of tires, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

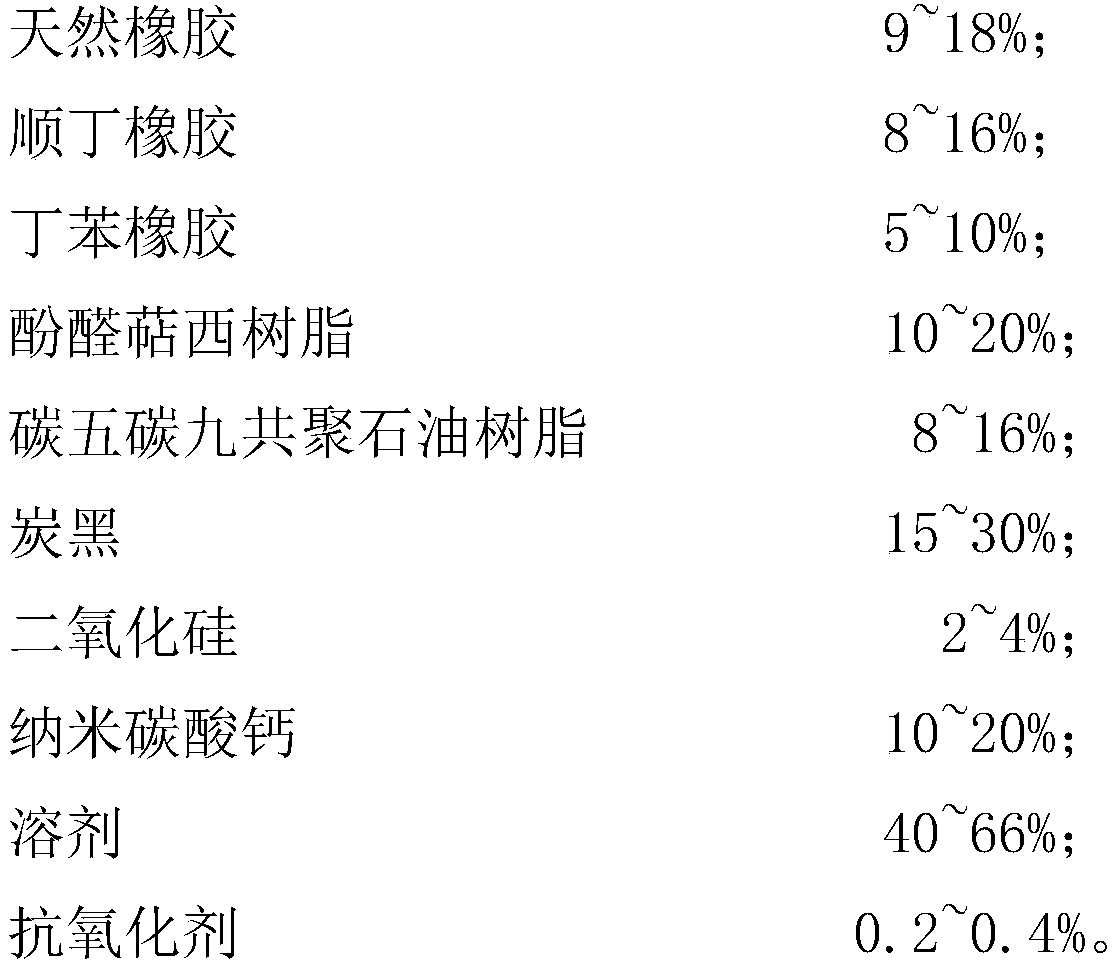

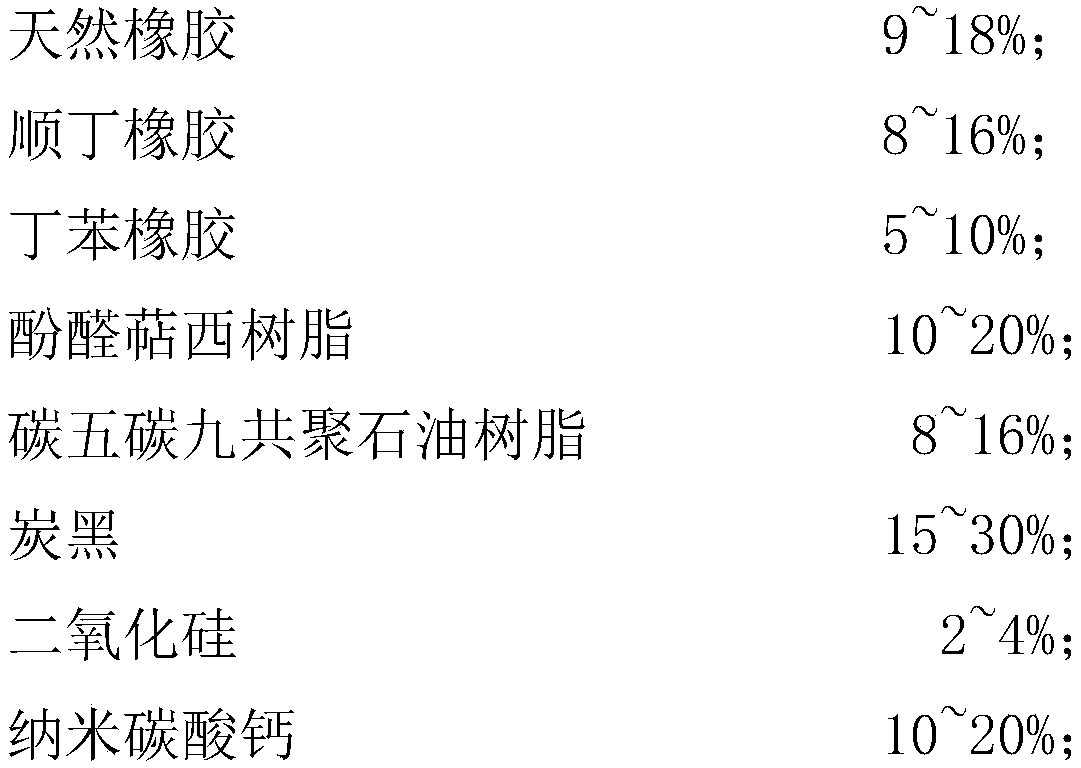

[0043] 1) earlier the natural rubber of 9% by weight is cut into small pieces, put on the rubber mixing machine and refine 5 times, cut into flake small pieces for later use, then cut the butadiene rubber of 8% by weight into small pieces, put Refine 5 times on the rubber mixer, cut into flakes for later use, then cut 5% styrene-butadiene rubber into smaller pieces, put it on the rubber mixer and refine for 5 times, cut into flakes for later use;

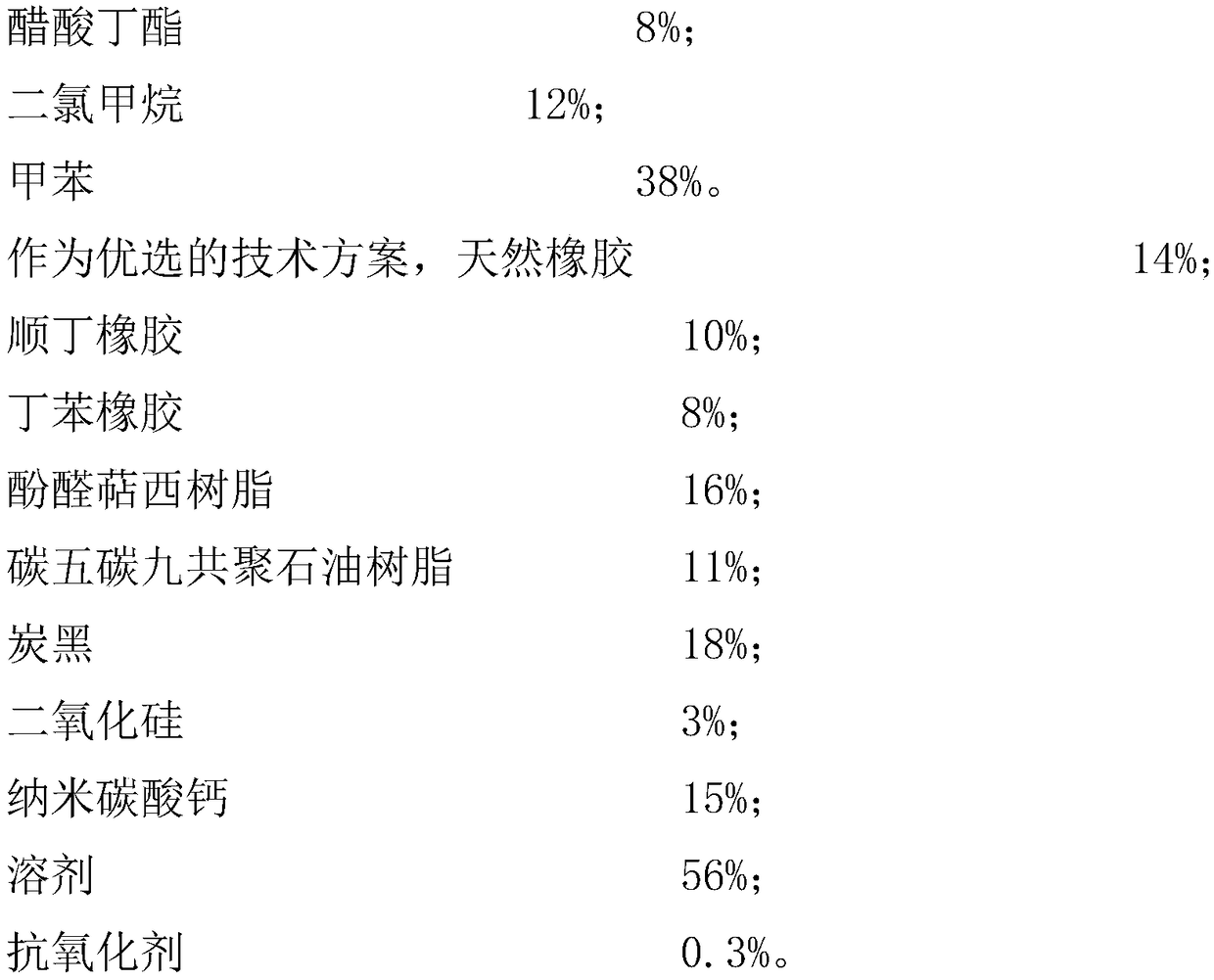

[0044] 2) Put the solvent of 40% by weight into the reactor, take step 1) refined natural rubber film, cis-butadiene rubber film, and styrene-butadiene rubber film one by one and drop into the reactor one by one, after stirring for 24 hours, wait for After the films in the reactor were all dissolved, add 10% by weight of phenolic terpene resin, 8% by weight of C5C9 copolymerized petroleum resin in the reactor, then add 0.2% by weight of antioxidant, stir for 4 hours standby;

[0045] 3) After the stirring is completed, the stirring...

Embodiment 2

[0049] 1) earlier cut the natural rubber of 18% by weight into small pieces, put it on the rubber mixing machine and refine it 8 times, cut into flake small pieces for later use, then cut the butadiene rubber of 16% by weight into small pieces, put Refine 8 times on the rubber mixer, cut into flakes for later use, then cut 10% styrene-butadiene rubber into smaller pieces, put it on the rubber mixer and refine 8 times, cut into flakes for later use;

[0050] 2) Put 40-66% of the solvent by weight into the reactor, take step 1) refined natural rubber film, butadiene rubber film, and styrene-butadiene rubber film one by one and put them into the reactor one by one, and stir for 26 hours After the film in the reactor is all dissolved, add 20% by weight of the phenolic terpene resin, 16% by weight of the carbon five carbon nine copolymerized petroleum resin in the reactor, then add the antioxidant of 0.4% by weight, Stir for 6 hours and set aside;

[0051] 3) After the stirring is...

Embodiment 3

[0055] 1) First cut the natural rubber of 14% by weight into small pieces, put it on the rubber mixing machine and refine it 8 times, cut into flake small pieces for use, then cut the 10% butadiene rubber into small pieces, put Refine 8 times on the rubber mixer, cut into flakes for later use, then cut 8% styrene-butadiene rubber into smaller pieces, put it on the rubber mixer and refine for 8 times, cut into flakes for later use;

[0056] 2) Put the solvent of 56% by weight into the reactor, take step 1) refined natural rubber film, cis-butadiene rubber film, and styrene-butadiene rubber film one by one and drop into the reactor one by one, after stirring for 25 hours, wait for After the films in the reactor were all dissolved, add 16% by weight of phenolic terpene resin, 11% by weight of C5C9 copolymerized petroleum resin in the reactor, then add 0.3% by weight of the antioxidant, stir for 5 hours standby;

[0057] 3) After the stirring is completed, the stirring will gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com