Method and special equipment for adding catalyst in polymerization reaction of terpene resin production

A terpene resin and polymerization reaction technology, which is applied in the field of chemical production equipment, can solve the problems of endangering human health, catalysts are easy to be affected by moisture, and materials are easy to wash out, etc., and achieve the effects of ensuring human health, easing the reaction of materials, and adding at a slow and uniform speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

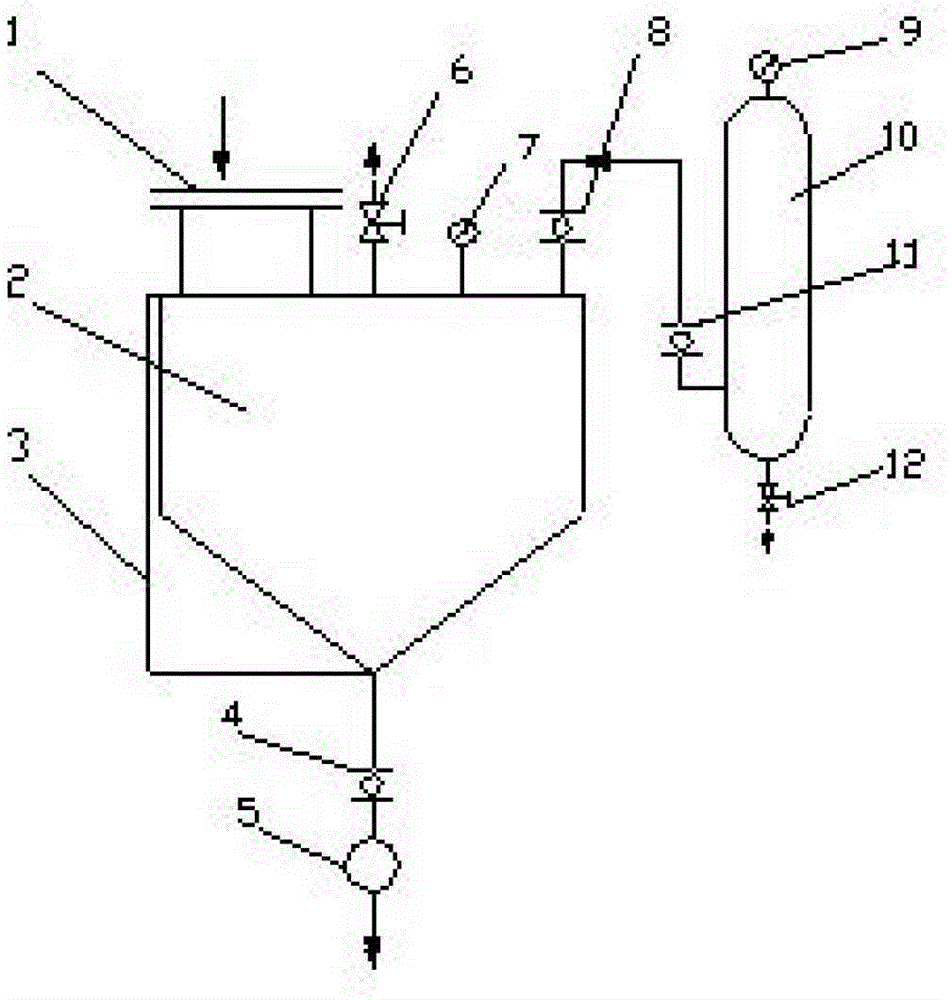

[0024] refer to figure 1 , the special equipment involved in this embodiment includes a feed tank 2 and a nitrogen buffer tank 10, the discharge port at the bottom of the feed tank 2 is provided with a discharge butterfly valve 4, and the top of the feed tank 2 is provided with a closable catalyst feed port 1, venting Valve 6, pressure gauge 7 and nitrogen input port, the gas output end of nitrogen buffer tank 10 is connected to the nitrogen input port of feeding tank 2 through regulating valve 11 and gas filling valve 8; a sight glass barrel is provided at the output end of discharging butterfly valve 4 5. An external port is formed to facilitate the observation of the catalyst feeding rate and dosage through the viewing tube 5; a transparent scale 3 is provided on the side wall of the feeding tank 2 to facilitate the observation of the catalyst stock in the feeding tank 2.

[0025] In this example:

[0026] The upper part of the feeding tank 2 is cylindrical and the lower p...

specific Embodiment 2

[0035] The characteristics of this specific embodiment 2 are: the upper part of the feeding tank 2 is in the shape of a polygonal cylinder, and the lower part is in the shape of a polygonal cone. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com