Aqueous polymer dispersion and process

A dispersion and polymer technology, applied in the direction of graft polymer adhesives, adhesive types, coatings, etc., can solve the problem of not prompting, stabilizing tackifiers and microemulsions at the same time, combining tackifiers, etc. question

Inactive Publication Date: 2009-09-02

CYTEC SURFACE SPECIALTIES INC

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0022] None of the existing literature suggests the incorporation of tackifiers in the dispersed hydrophobic phase of microemulsions, and given the difficulty of simultaneously stabilizing both tackifiers and microemulsions, there is every reason not to do so

Method used

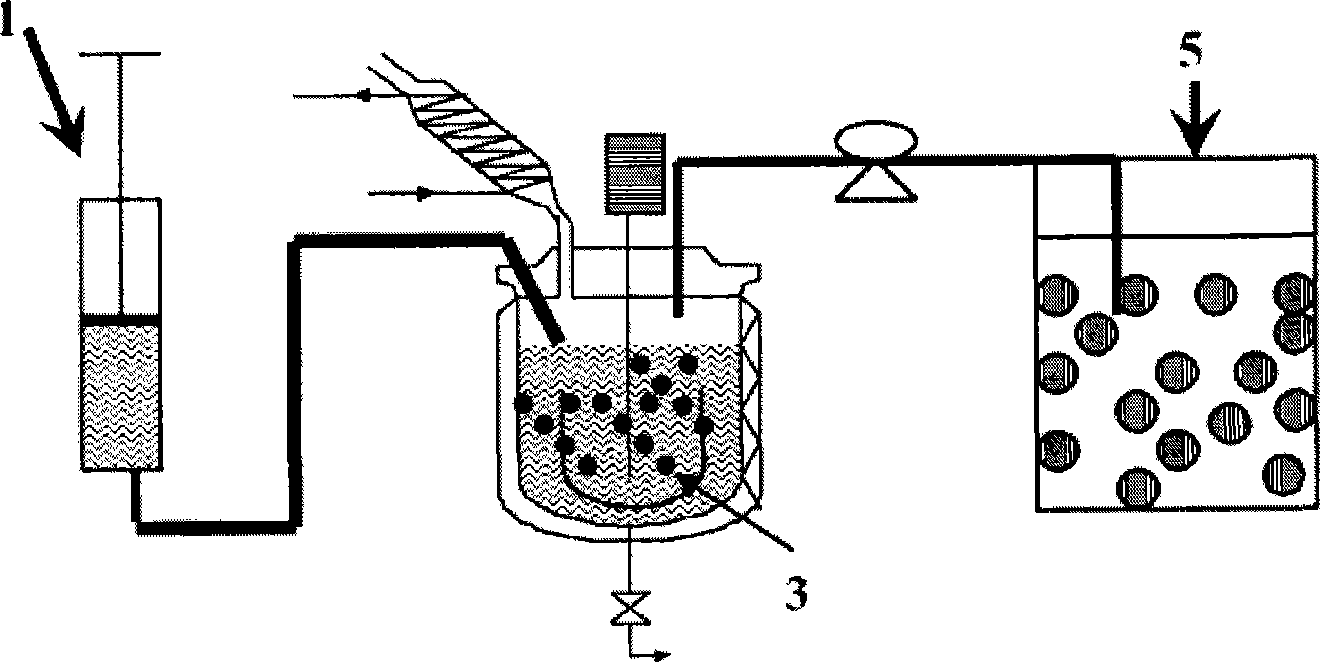

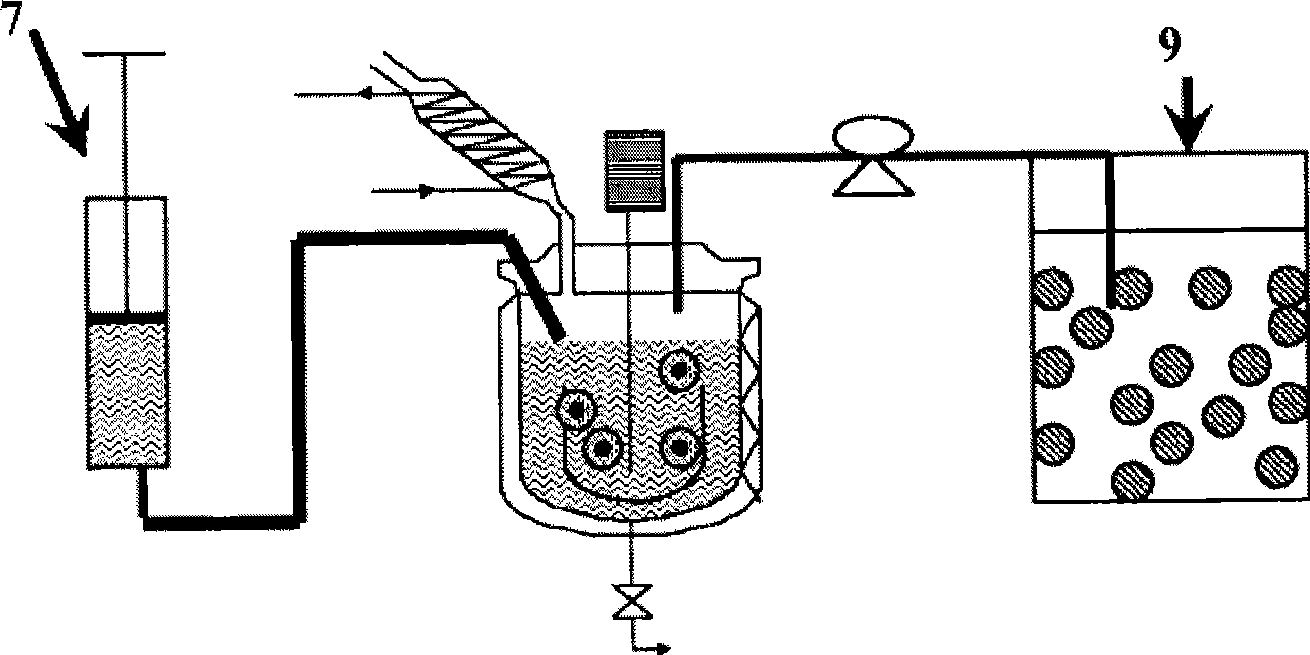

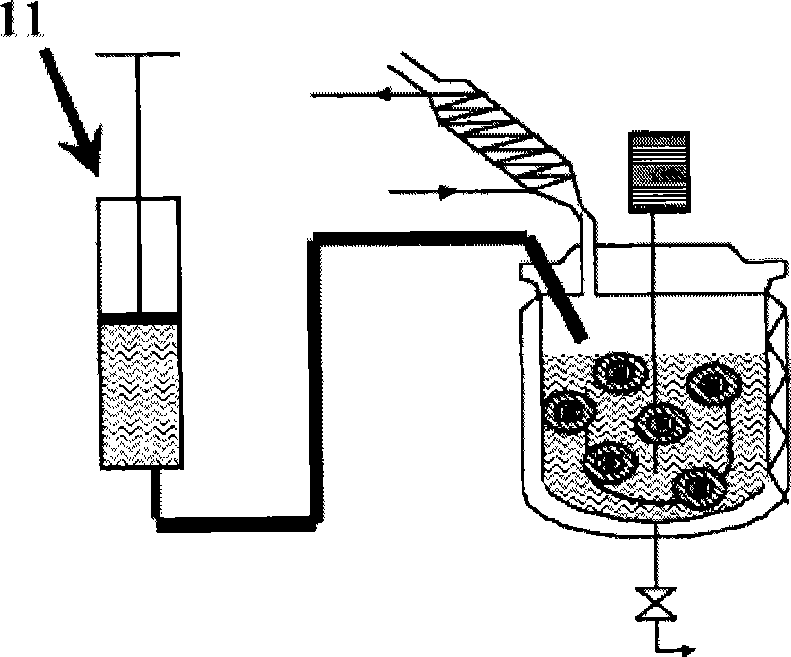

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0251] Table 1

[0252]

Embodiment 1

[0253] Embodiment 1 (continued on next page)

[0254] Embodiment 1 (continued)

[0255] Table 1 (continued)

[0256]

example 2

[0258] Table 2

[0259]

[0260] Example 2 (continued on next page)

[0261] Example 2 (continued)

[0262] Table 2 (continued)

[0263]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

There is described a multi step process for preparing an aqueous dispersion of heterogeneous polymer particles by mini-emulsion polymerisation, the process comprising the steps of (I) (a) forming a mixture comprising: (i) water; (ii) at least one stabiliser (such as a surfactant and a hydrophobic co-stabliiser); (iii) at least one tackifier (such as polyterpenes, rosin resins and / or hydrocarbon resins); (iv) at least one +-,-ethylenically unsaturated monomer;, (b) applying high shear to the mixture from step (a) to form an essentially stable mini-emulsion comprising an aqueous continuous phaseand dispersed therein stabilised droplets of average diameter from about 10 to about 1000 nm, (c) polymerising the monomer(s) within the droplets in the presence of a free radical initiator; (d) adding further monomer to the dispersed phase to form a dispersion; then: (II) using the dispersion from step (I) as a seed to form a dispersion of heterogeneous polymer particles in a subsequent emulsionpolymerisation. The resultant tackified PSAs may have a core shell structure and are stable under high shear.

Description

technical field [0001] The present invention relates to the field of pressure sensitive adhesives (PSAs) comprising tackified acrylic emulsions. Background technique [0002] It is desirable for PSA emulsions to have higher adhesion to a variety of substrates such as substrates with lower surface energies such as polymeric films and other substrate types such as cardboard. One of the ways to achieve this is to add tackifiers such as polyterpenes, rosin resins and / or hydrocarbons. Addition of tackifiers to emulsions, however, can have an adverse effect on the stability of aqueous latexes, especially when the latex is subjected to high shear. [0003] Dispersions of tackifiers in water are unstable under high shear due to coagulation. For example, hydrocarbon tackifiers are usually at 4000 to 5000s -1 coagulation at higher shear rates. When this tackifier dispersion is added to a conventional acrylic PSA emulsion, the resulting mixture also coagulates under high shear. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F2/22C08F2/26C08F265/04C08F265/06C08F257/02C08L51/00C09D151/00C09J151/00C09D11/00

CPCC08F2/22C08F2/26C09D151/003C08F257/02C08F265/04C09J151/003C08F220/18C08F265/06C08F220/28C08L51/003C08L2666/02C08F220/1818C08F220/1802C08F220/283C08F220/1804C08J3/02

Inventor 凯尔顿·乌兹纳郭众胜奥古斯丁·陈江盛里欧·泰尔诺卢斯盖

Owner CYTEC SURFACE SPECIALTIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com