Catalytic composition for producing 1-alkene and acrylates copolymer and method for producing 1-alkene and acrylates copolymer

A technology for acrylates and copolymers, applied in the field of catalytic compositions for preparing 1-alkene and acrylate copolymers and the preparation of 1-alkenes and acrylate copolymers, can solve the problem of low content of polar monomers, etc. achieve easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

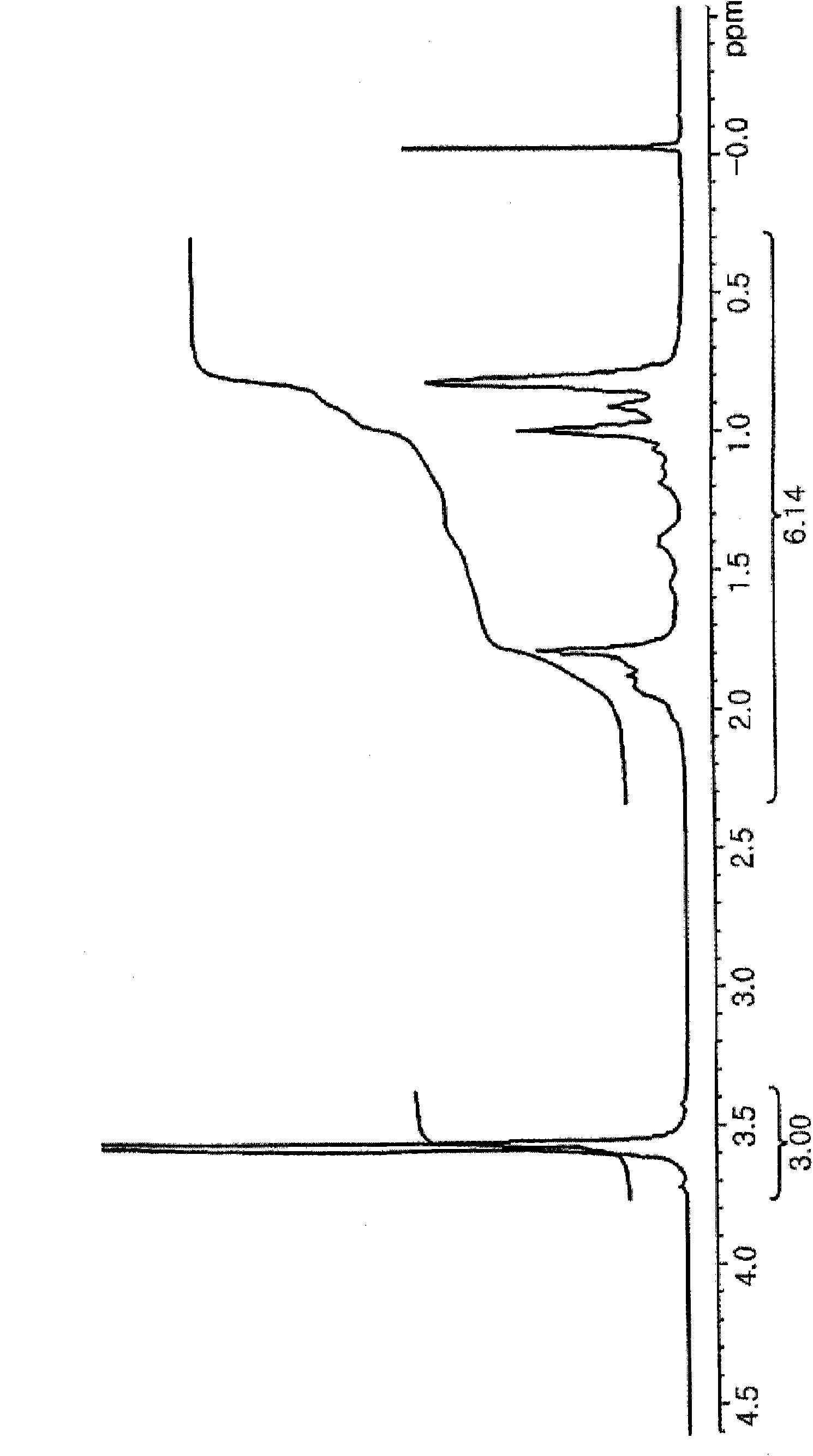

[0091] After the 125mL high-pressure reactor was evacuated, it was filled with argon. Under an argon atmosphere, a metal nanocatalyst (2.86 g, 28.05 mmol) containing 0.1 wt% ruthenium, 23 mL of toluene, and methyl methacrylate (2.81 g, 28.05 mmol) were added to the reactor. Separately, 0.056 mmol of initiator AIBN dissolved in toluene was added. Then, after charging ethylene at a pressure of 30 bar, the temperature of the reactor was raised to 70° C., stirred at a rate of 500 rpm with a magnetic bar, and polymerized for 18 hours to prepare a polymer solution.

[0092] After the polymerization reaction is completed, the reaction temperature is lowered to normal temperature, and the metal nano-catalyst is recovered by filtration. Subsequently, ethanol not used as a solvent was added dropwise to the polymer solution from which the metal nanocatalyst was removed to precipitate the polymer in a solid form. The supernatant was removed by precipitating the solid phase, ethanol was ...

Embodiment 2

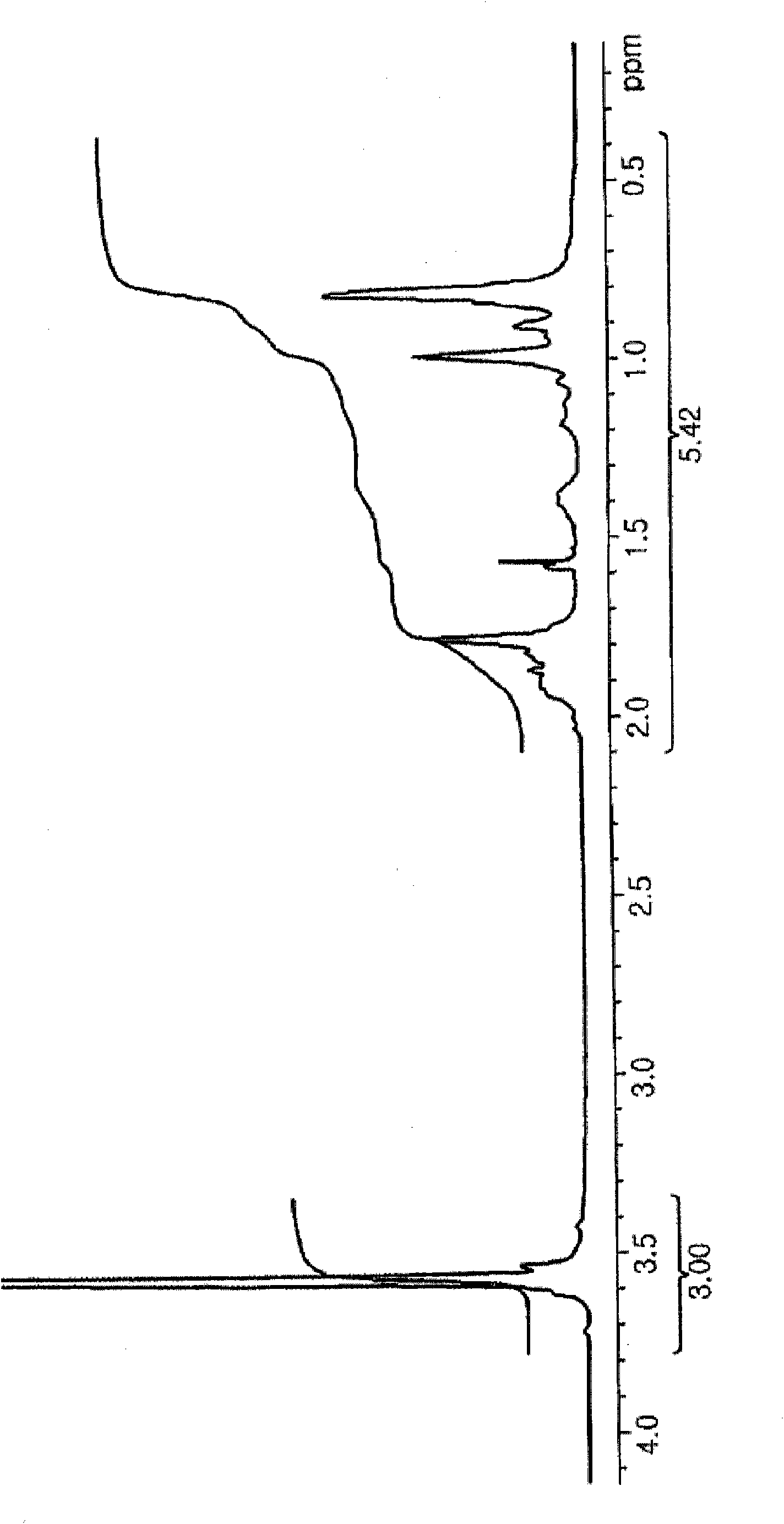

[0094] Except for using a metal nanocatalyst containing 1 wt% ruthenium, the same polymerization conditions and post-treatment process as in Example 1 were used to prepare a copolymer.

Embodiment 3

[0096] Except for using a metal nanocatalyst containing 5 wt% ruthenium, the same polymerization conditions and post-treatment process as in Example 1 were used to prepare a copolymer.

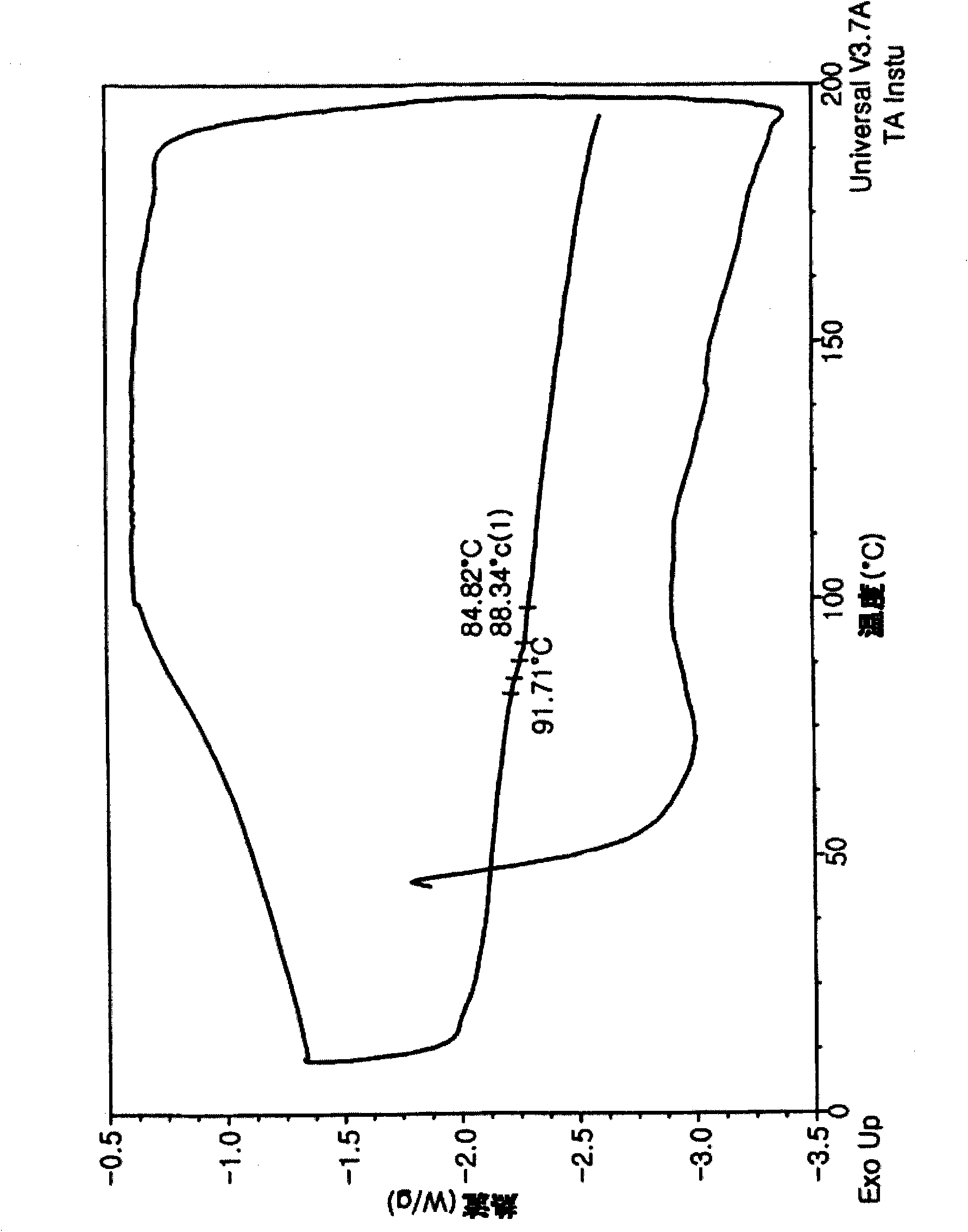

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com