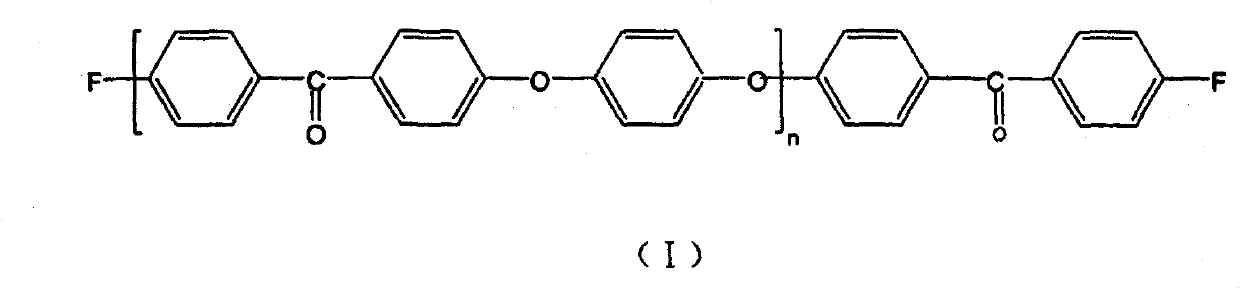

High-strength carbon fiber reinforced polyether-ether-ketone composite material and preparation method thereof

A technology of high-strength carbon fiber and polyetheretherketone, which is applied in the field of high-strength carbon fiber-reinforced polyether ether ketone composite materials and its preparation, can solve the problems of low heat resistance, poor compatibility, and inability to play a compatibilizing role. problem, to achieve the effect of low heat resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

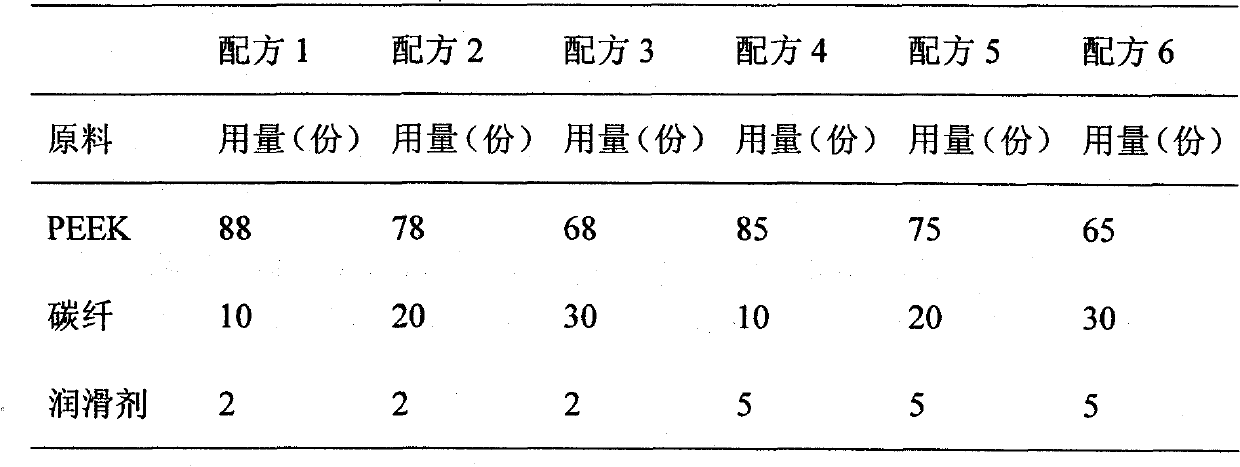

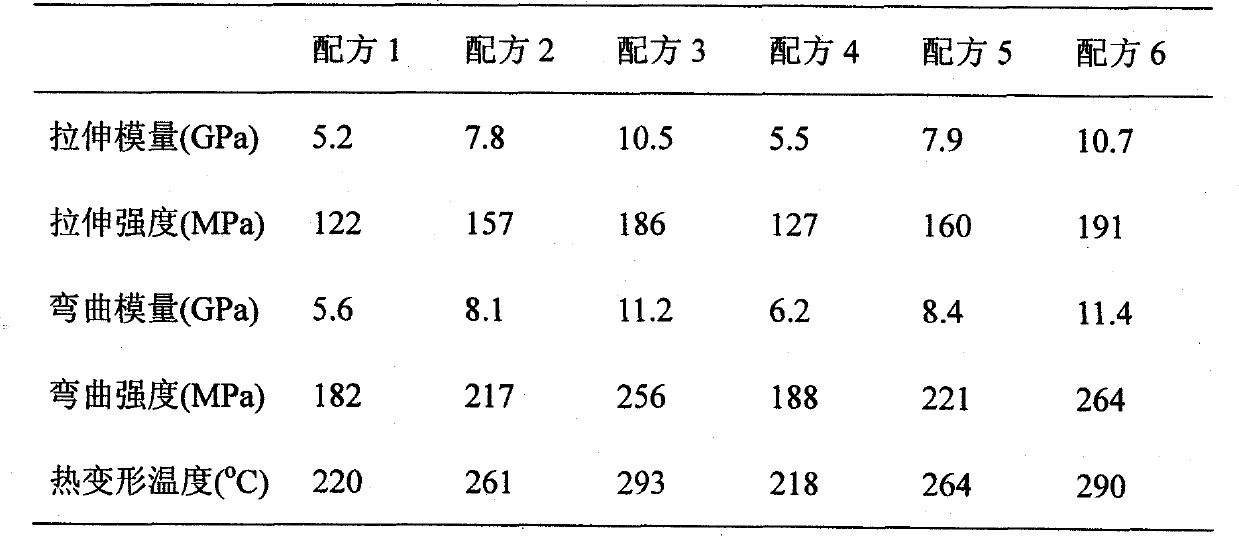

Embodiment 1

[0017] Set the temperature of each process section of the twin-screw extruder to 320°C, 340°C, 355°C, 355°C, 355°C, 355°C, 355°C, 355°C, 350°C, 340°C. After the temperature reaches the set value, first Turn on the first loss-in-weight scale, add PEEK powder from the main feeding port at a feeding speed of 20Kg / h, wherein the PEEK melt index is 21g / 10min, after the PEEK is extruded from the die, open the second loss-in-weight scale, Add high-temperature-resistant lubricant at a speed of 2.27Kg / h and control the twin-screw speed to 300-500Rad / min after the extruder runs stably. , the torque does not exceed 80%, the head melt temperature does not exceed 400°C, and a composite material with a PEEK content of 88%, a high-temperature resistant lubricant content of 2%, and a carbon fiber content of 10% is obtained. Adjust the feeding parameters to obtain different formulas, the formulas are shown in Table 1, and the properties of each formula are shown in Table 2.

[0018] Table 1 C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com