Curing agent for pure polyester powder coating system and preparation method thereof

A technology of polyester powder and curing agent, used in powder coatings, polyester coatings, coatings, etc., can solve the problems of insufficient leveling on the surface of the coating film, prone to pinholes, unsatisfactory application or application effect, etc. Enhance outdoor weather resistance, moderate speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

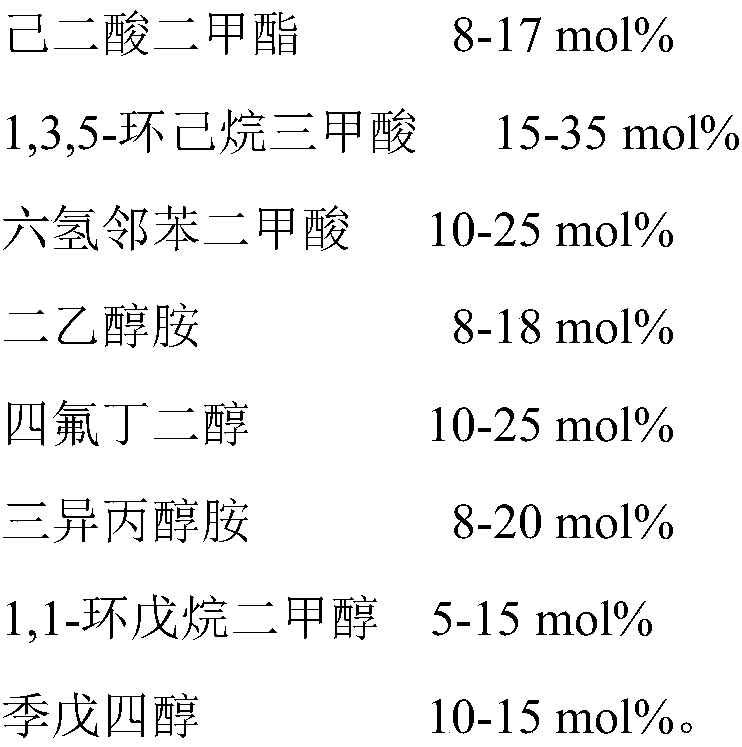

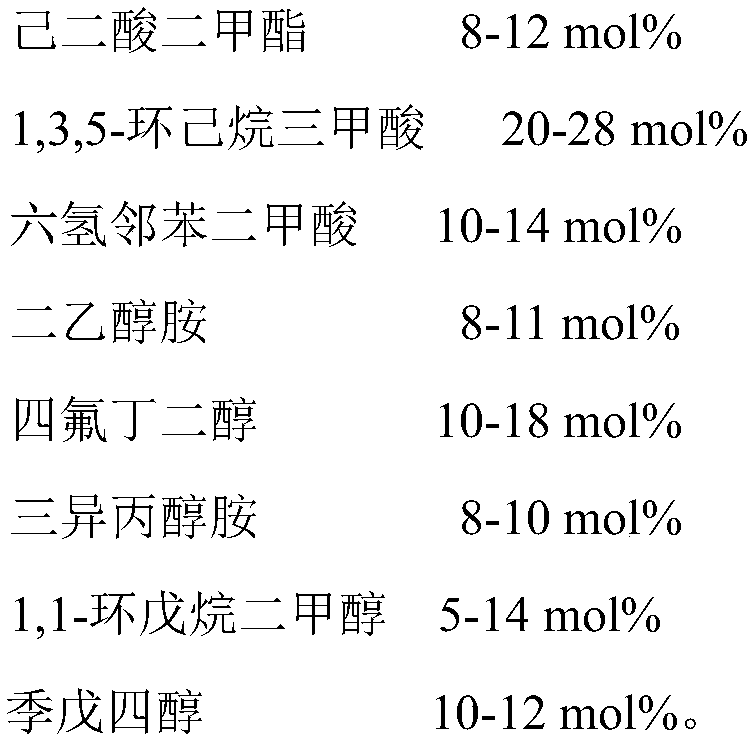

Method used

Image

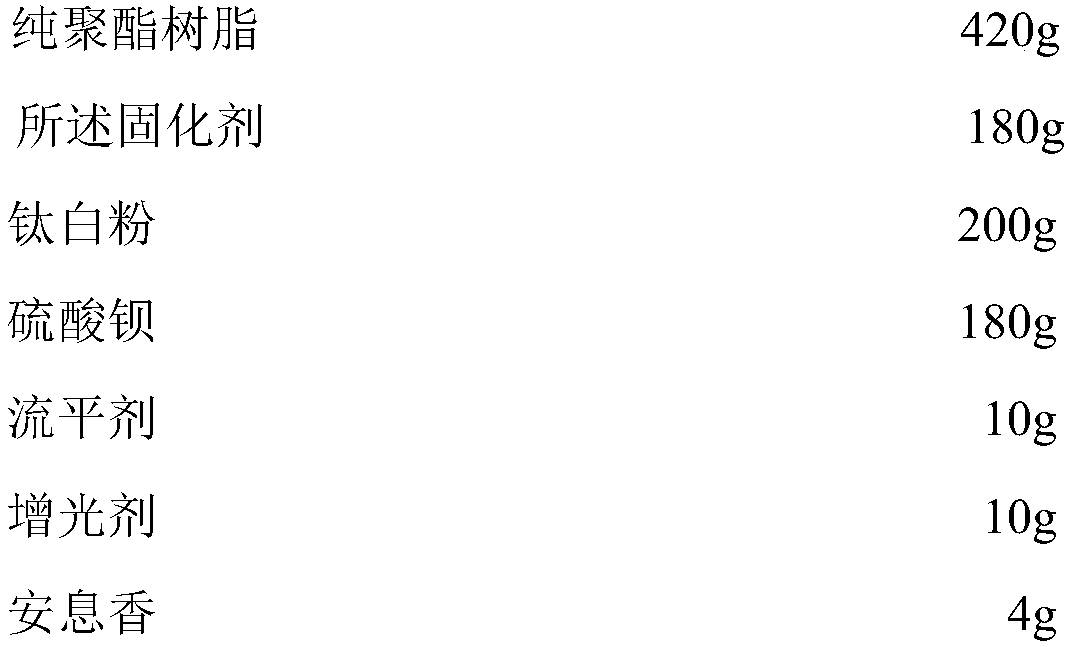

Examples

Embodiment 1

[0029] A curing agent composition for pure polyester powder coating system, the components include 15 mol of dimethyl adipate, 25 mol of 1,3,5-cyclohexanetricarboxylic acid, 10 mol of hexahydrophthalic acid, 8 mol of diethanolamine, Tetrafluorobutanediol 10mol, triisopropanolamine 8mol, 1,1-cyclopentanedimethanol 14mol, pentaerythritol 10mol, tetraethoxytitanium 0.2mol, antioxidant 300, 0.3mol.

[0030] The preparation method of described pure polyester powder coating system hardener composition is, comprises and steps:

[0031] A. Add diethanolamine, tetrafluorobutanediol, triisopropanolamine, and 1,1-cyclopentanedimethanol into the reactor, and heat and melt at 105°C;

[0032] B, add the dimethyl adipate of formula quantity, 1,3,5-cyclohexane tricarboxylic acid, hexahydrophthalic acid in above-mentioned mixture material, add the catalyst tetraethoxytitanium of formula quantity simultaneously, in Under the protection of nitrogen, gradually increase the temperature until no o...

Embodiment 2

[0038] A curing agent composition for a pure polyester powder coating system, the components include dimethyl adipate 8mol, 1,3,5-cyclohexanetricarboxylic acid 28mol, hexahydrophthalic acid 12mol, diethanolamine 9mol, Tetrafluorobutanediol 18mol, triisopropanolamine 9mol, 1,1-cyclopentanedimethanol 6mol, pentaerythritol 10mol, tetraethoxytitanium 0.3mol, antioxidant 300, 0.4mol.

[0039] The preparation method is the same as in Example 1.

[0040] Prepared curing agent product index:

[0041] Appearance: Colorless transparent particles, the hydroxyl value is 242mgKOH / g, and the softening point is 121°C.

Embodiment 3

[0043] A curing agent composition for pure polyester powder coating system, the components include 15 mol of dimethyl adipate, 23 mol of 1,3,5-cyclohexanetricarboxylic acid, 11 mol of hexahydrophthalic acid, 11 mol of diethanolamine, Tetrafluorobutanediol 15mol, triisopropanolamine 10mol, 1,1-cyclopentanedimethanol 5mol, pentaerythritol 10mol, tetraethoxytitanium 0.2mol, antioxidant 300, 0.4mol.

[0044] The preparation method is the same as in Example 1.

[0045] Prepared curing agent product index:

[0046] Appearance: Colorless transparent particles, the hydroxyl value is 212mgKOH / g, and the softening point is 115°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com