Method for preparing hexahydrophthalic anhydride

A technology of hexahydrophthalic anhydride and phthalic anhydride, which is applied in the field of fine chemical synthesis, can solve the problems of insufficient utilization of hexahydrophthalic anhydride, high requirements for catalyst hydrogenation activity, etc., achieves good economic benefits and industrial application prospects, improves productivity, and improves operation flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

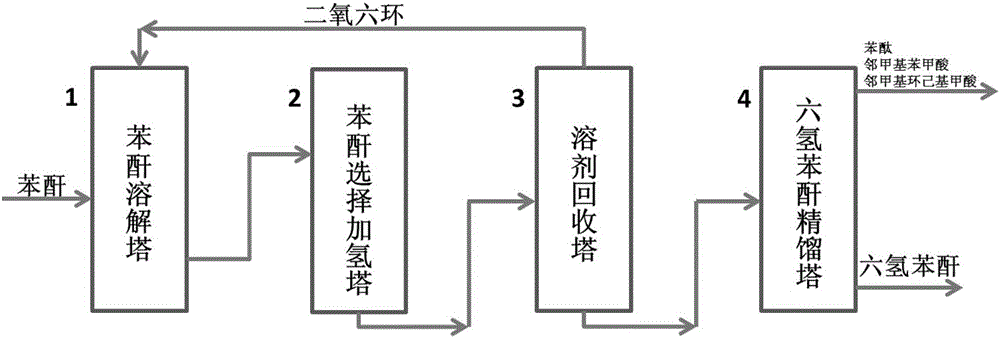

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of eggshell type PdRu catalyst to form Al 2 O 3 , MgO, ZnO, TiO 2 As carrier, with PdCl 2 And RuCl 3 It is a metal precursor that uses reactive deposition to prepare eggshell-type PdRu / Al 2 O 3 , PdRu / MgO, PdRu / ZnO, PdRu / TiO 2 Catalyst, reactive deposition is the use of rapid reduction reaction to deposit metal particles on the surface of the carrier. The metal ratio can be controlled by controlling the ratio of metal precursors. The eggshell catalyst can be controlled by controlling the system viscosity, carrier surface properties, and metal ion reduction speed. Layer thickness. By controlling experimental conditions, eggshell catalysts with different metal ratios and loadings were prepared. The eggshell catalyst is beneficial to the separation of the intermediate products of the hydrogenation reaction. For the hydrogenation of phthalic anhydride to prepare hexahydrophthalic anhydride, the eggshell catalyst can significantly improve the selectivity...

Embodiment 2

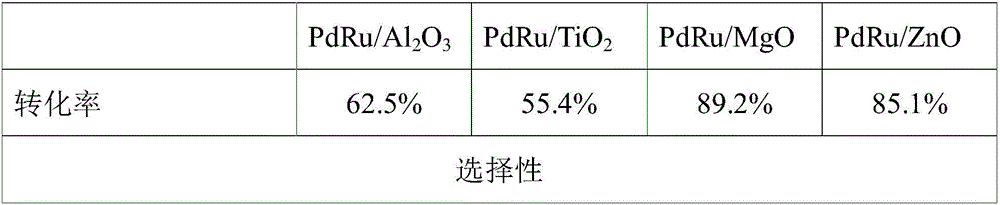

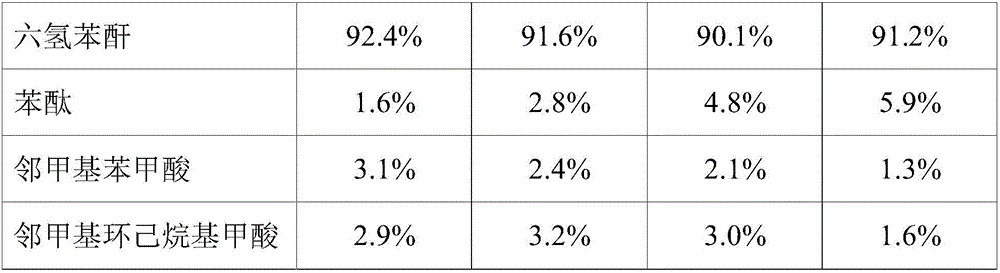

[0023] Example 2: Prepare different carrier eggshell type PdRu / Al with Pd loading of 0.1% and Ru loading of 0.8% 2 O 3 , PdRu / MgO, PdRu / ZnO, PdRu / TiO 2 The catalyst is used in the constant-pressure tank reaction to prepare hexahydrophthalic anhydride. For PdRu / Al 2 O 3 And PdRu / TiO 2 The catalyst, after reducing the above catalyst at 300℃ for 2h, pour it into a dioxane constant pressure reactor filled with 10% phthalic anhydride, and then add the auxiliary Na 2 CO 3 Or NaOH, the reaction conditions are: the reaction pressure is 10MPa, the reaction temperature is 100°C, the mass ratio of the substrate to the catalyst is 5:1, the reaction time is 8h, and the mass of the auxiliary agent is 5% of the substrate. The role of the auxiliary agent is: one is to inhibit the hydrolysis of phthalic anhydride and hexahydrophthalic anhydride, the second is to inhibit the hydrogenation of the side chain of p-phthalic anhydride, and the third is the water produced during the adsorption reaction. ...

Embodiment 3

[0026] Example 3: Eggshell PdRu / Al with Pd loading of 0.1% and Ru loading of 0.8% 2 O 3 The catalyst, after reducing the above catalyst at 300℃ for 2h, pour it into a constant pressure reactor containing 10% phthalic anhydride, dioxane, tetrahydrofuran, cyclohexane and decalin, and then add the auxiliary Na 2 CO 3 The reaction conditions are: reaction pressure 10MPa, reaction temperature 100°C, substrate to catalyst mass ratio 5:1, reaction time 8h, and auxiliary agent mass 5% of the substrate. Table 2 below shows the results of selective hydrogenation of phthalic anhydride to hexahydrophthalic anhydride as a solvent.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com