Epoxy powder coating for pipeline and preparation method of epoxy powder coating

An epoxy powder and coating technology, applied in powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of unsatisfactory needs, high cost, single variety, etc., and achieve low production cost, long service life, and weather resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

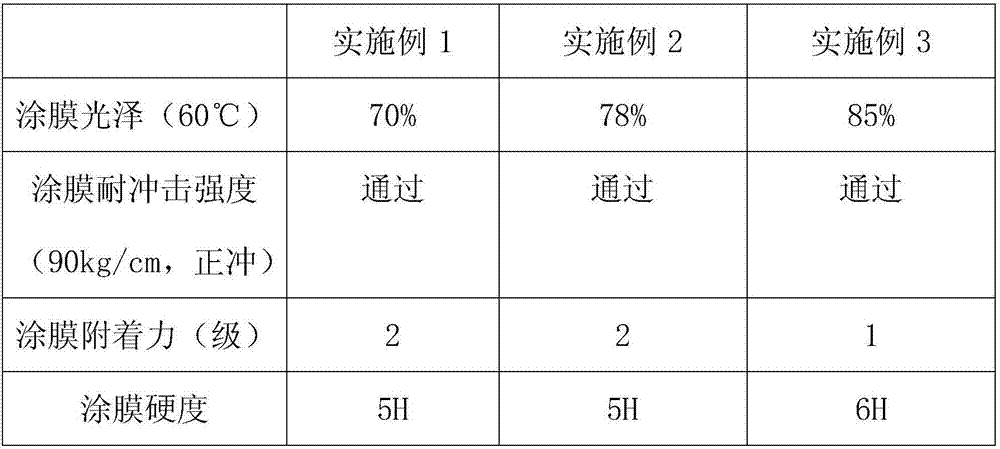

Embodiment 1

[0016] An epoxy powder coating for pipelines, the raw material components are: 50 parts of diglycidyl hexahydrophthalate, 10 parts of polyester resin, 0.1 part of choline chloride, 0.5 part of benzoin , 20 parts of titanium dioxide, 10 parts of light calcium carbonate, 0.5 parts of leveling agent, 0.5 parts of powder flow aid, 5 parts of talcum powder, 0.5 parts of edge covering agent, 0.1 part of anti-caking agent, and 1 part of pigment. The particle size of titanium dioxide, light calcium carbonate and talcum powder is 800 mesh. The powder flow aid is charge-modified low-molecular-weight polyethylene, and the particle size of polyethylene is 800 mesh.

[0017] A kind of epoxy powder coating preparation method for pipeline, its preparation steps are as follows:

[0018] S1, each raw material is weighed by the weight part of composition raw material;

[0019] S2. The selected diglycidyl hexahydrophthalate, polyester resin, choline chloride, benzoin, titanium dioxide, light c...

Embodiment 2

[0023] An epoxy powder coating for pipelines, the raw material components are: 60 parts of diglycidyl hexahydrophthalate, 20 parts of polyester resin, 0.5 parts of choline chloride, and 1 part of benzoin , 30 parts of titanium dioxide, 20 parts of light calcium carbonate, 1 part of leveling agent, 1.5 parts of powder flow aid, 10 parts of talcum powder, 1.5 parts of edge covering agent, 0.5 parts of anti-caking agent, 3 parts of pigment. The particle size of titanium dioxide, light calcium carbonate and talcum powder is 800 mesh. The powder flow aid is charge-modified low-molecular-weight polyethylene, and the particle size of polyethylene is 800 mesh.

[0024] A kind of epoxy powder coating preparation method for pipeline, its preparation steps are as follows:

[0025] S1, each raw material is weighed by the weight part of composition raw material;

[0026] S2. The selected diglycidyl hexahydrophthalate, polyester resin, choline chloride, benzoin, titanium dioxide, light ca...

Embodiment 3

[0030] An epoxy powder coating for pipelines, the raw material components are: 55 parts of diglycidyl hexahydrophthalate, 15 parts of polyester resin, 0.3 parts of choline chloride, 0.7 parts of benzoin , 25 parts of titanium dioxide, 15 parts of light calcium carbonate, 0.8 parts of leveling agent, 1 part of powder flow aid, 8 parts of talcum powder, 1 part of edge covering agent, 1 part of anti-caking agent, and 2 parts of pigment. The particle size of titanium dioxide, light calcium carbonate and talcum powder is 800 mesh. The powder flow aid is charge-modified low-molecular-weight polyethylene, and the particle size of polyethylene is 800 mesh.

[0031] A kind of epoxy powder coating preparation method for pipeline, its preparation steps are as follows:

[0032] S1, each raw material is weighed by the weight part of composition raw material;

[0033] S2. The selected diglycidyl hexahydrophthalate, polyester resin, choline chloride, benzoin, titanium dioxide, light calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com