High-performance water-based resin and preparation method thereof

A water-based resin, high-performance technology, used in the preparation of high-performance water-based resins, can solve the problems of slow drying, low hardness, poor water resistance and corrosion resistance, and achieve reduced drying time of the coating film, good water solubility and dryness. and improved adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

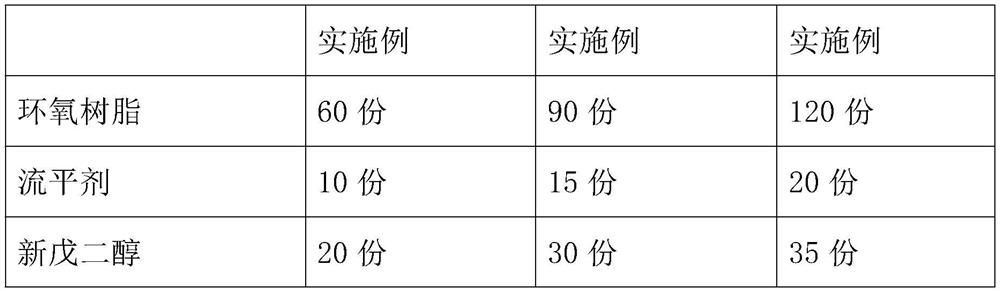

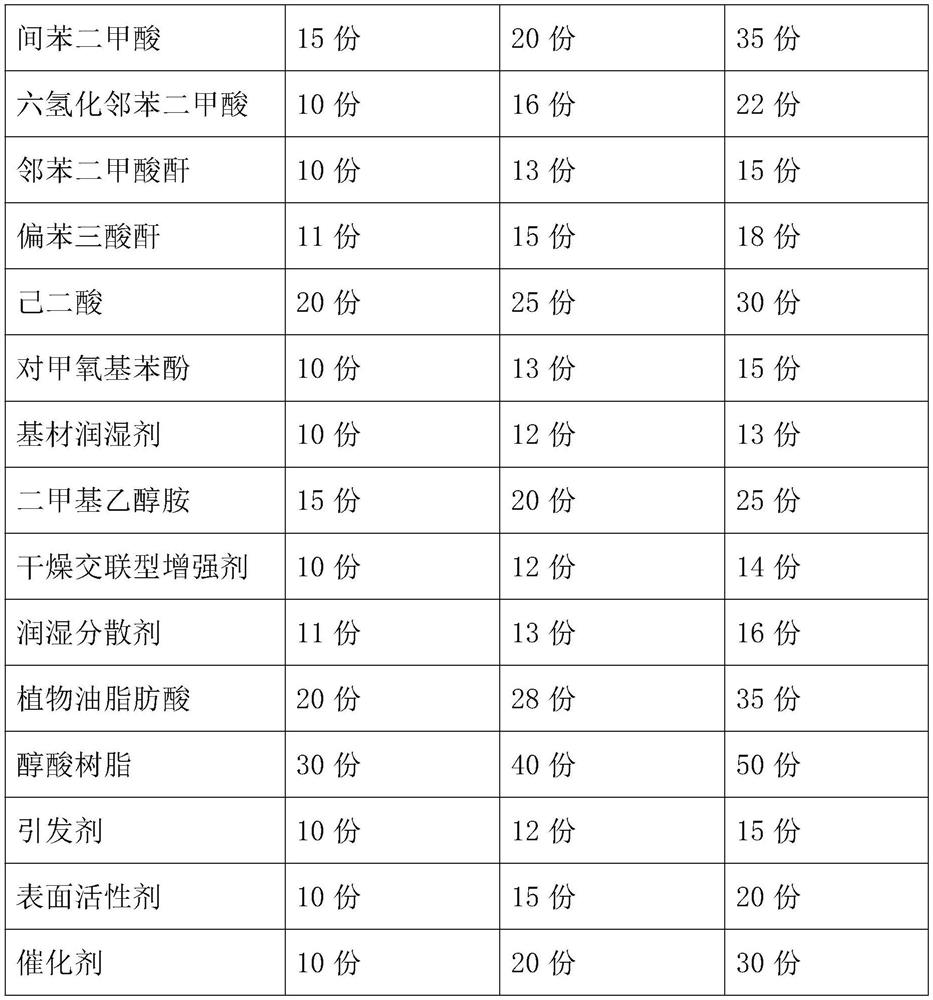

[0023] A high-performance water-based resin, in parts by mass, the formula of the high-performance water-based resin includes: 60 parts of epoxy resin, 10 parts of leveling agent, 20 parts of neopentyl glycol, 15 parts of isophthalic acid, hexahydrogenated 10 parts of phthalic acid, 10 parts of phthalic anhydride, 11 parts of trimellitic anhydride, 20 parts of adipic acid, 10 parts of p-methoxyphenol, 10 parts of substrate wetting agent, 15 parts of dimethylethanolamine, drying gel 10 parts of joint reinforcing agent, 11 parts of wetting and dispersing agent, 20 parts of vegetable oil fatty acid, 30 parts of alkyd resin, 10 parts of initiator, 10 parts of surfactant, and 10 parts of catalyst;

[0024] Wherein, the vegetable oil fatty acid includes: oleic acid, soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, sesame oil, camellia oil, rice bran oil, linseed oil, corn oil, safflower oil, palm oil , olive oil, tung oil or a mixture thereof;

[0025] The cata...

Embodiment 2

[0033] The difference in Example 1 is:

[0034] Optionally, in terms of parts by mass, the formula of the high-performance water-based resin includes: 90 parts of epoxy resin, 15 parts of leveling agent, 30 parts of neopentyl glycol, 20 parts of isophthalic acid, hexahydrophthalic acid 16 parts of formic acid, 13 parts of phthalic anhydride, 15 parts of trimellitic anhydride, 25 parts of adipic acid, 13 parts of p-methoxyphenol, 12 parts of substrate wetting agent, 20 parts of dimethylethanolamine, dry cross-linked reinforcement 12 parts of agent, 13 parts of wetting and dispersing agent, 28 parts of vegetable oil fatty acid, 40 parts of alkyd resin, 12 parts of initiator, 15 parts of surfactant, 20 parts of catalyst;

[0035] Wherein, the vegetable oil fatty acid includes: oleic acid, soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, sesame oil, camellia oil, rice bran oil, linseed oil, corn oil, safflower oil, palm oil , olive oil, tung oil or a mixture ...

Embodiment 3

[0038] The difference with embodiment 1 and embodiment 2 is:

[0039]Optionally, in terms of parts by mass, the formula of the high-performance water-based resin includes: 120 parts of epoxy resin, 20 parts of leveling agent, 35 parts of neopentyl glycol, 35 parts of isophthalic acid, hexahydrophthalic acid 22 parts of formic acid, 15 parts of phthalic anhydride, 18 parts of trimellitic anhydride, 30 parts of adipic acid, 15 parts of p-methoxyphenol, 13 parts of substrate wetting agent, 25 parts of dimethylethanolamine, dry cross-linked reinforcement 14 parts of agent, 16 parts of wetting and dispersing agent, 35 parts of vegetable oil fatty acid, 50 parts of alkyd resin, 15 parts of initiator, 20 parts of surfactant, 30 parts of catalyst;

[0040] Wherein, the vegetable oil fatty acid includes: oleic acid, soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, sesame oil, camellia oil, rice bran oil, linseed oil, corn oil, safflower oil, palm oil , olive oil, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com