Modified master batch for polyethylene films as well as preparation and use methods thereof

A technology of polyethylene film and polyethylene powder, which is applied in the field of modified masterbatch, can solve the problems of film tearing performance, falling dart impact strength, etc., and achieve the effect of improving film clarity and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

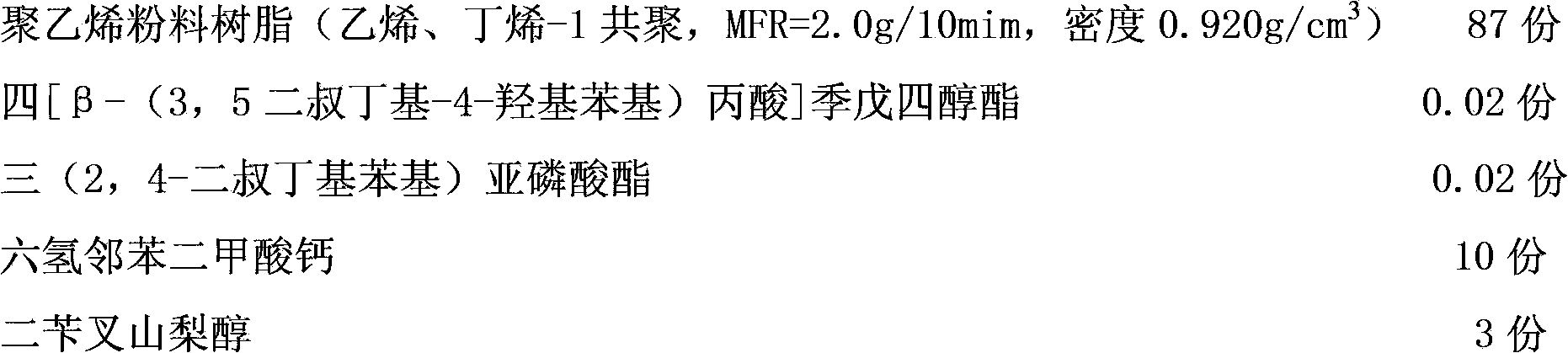

Examples

Embodiment 1

[0033] Polyethylene pellet resin (copolymerization of ethylene and butene-1, MFR=2.0g / 10mim, density 0.920g / cm 3 ) 99 copies

[0034] Modified masterbatch 1 1 parts

[0035] Screw aspect ratio: 30

[0036] Screw combination: 8 sections of shear block, 3 sections of reverse shear

[0037] Processing temperature: 190℃

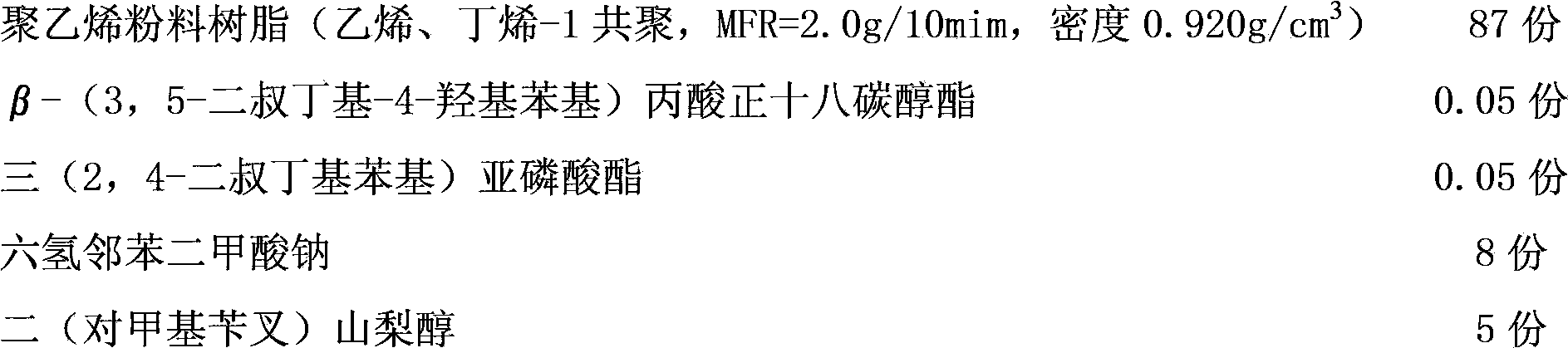

Embodiment 2

[0039] Polyethylene pellet resin (copolymerization of ethylene and butene-1, synthesized by slurry catalyst, MFR=2.0g / 10mim, density 0.918g / cm 3 )

[0040] 99 copies

[0041] Modified masterbatch 21 parts

[0042] High stirring blending direct blown film

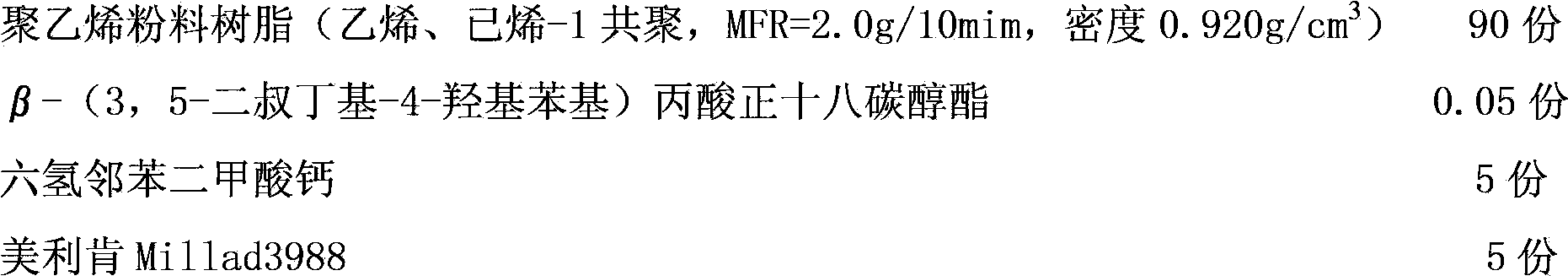

Embodiment 3

[0044] Polyethylene pellet resin (copolymerization of ethylene and hexene-1, synthesized by slurry catalyst, MFR=2.0g / 10mim, density 0.920g / cm 3 )

[0045] 98 copies

[0046] Modified masterbatch 3 2 parts

[0047] Screw aspect ratio: 35

[0048] Screw combination: 6 sections of shear block, 3 sections of reverse shear

[0049] Processing temperature: 200℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com